Spiral-wound membrane element winding method

A manufacturing method and roll-type membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low membrane utilization, easy accumulation of impurities, low membrane utilization, etc., to improve volume Production efficiency, short process, and improved anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment, but should not be interpreted as that the scope of the subject matter of the present invention is only limited to following embodiment, under the situation of not departing from above-mentioned technical thought of the present invention, all according to this field Various modifications, substitutions and alterations made by ordinary technical knowledge and common means are included in the scope of the present invention.

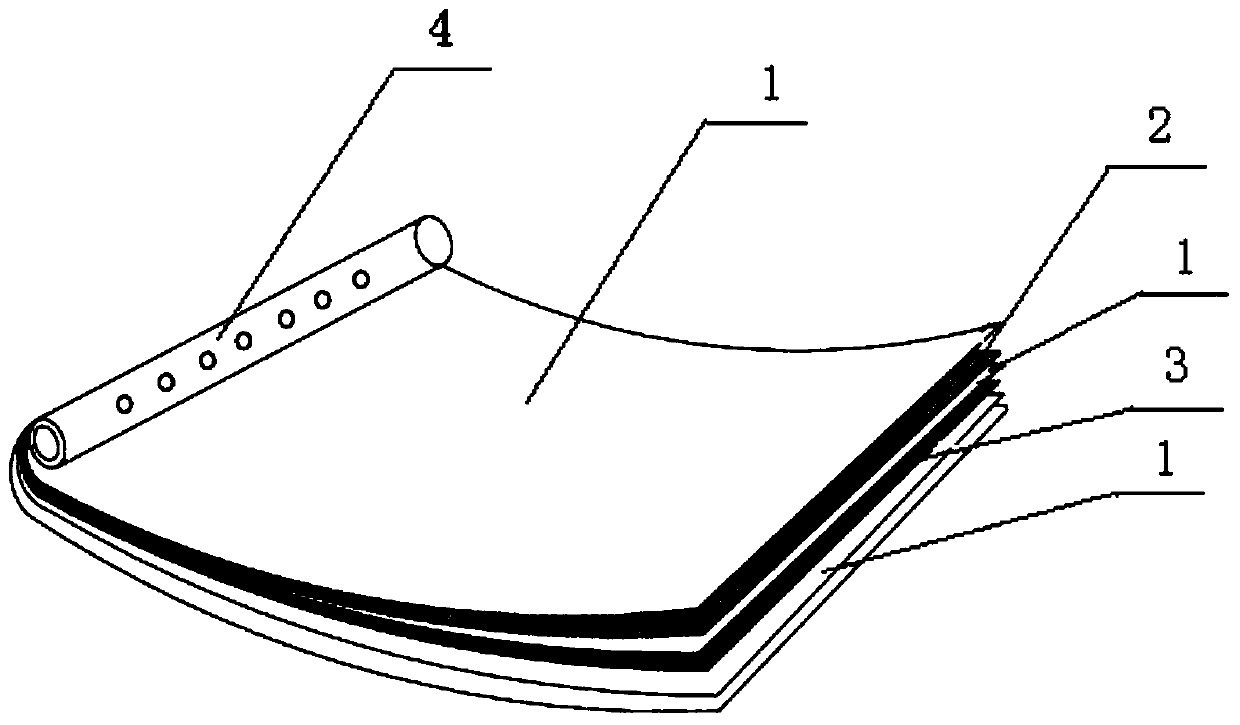

[0028] Such as figure 1 As shown, a method for rolling a roll-type membrane element according to the present invention includes the following steps:

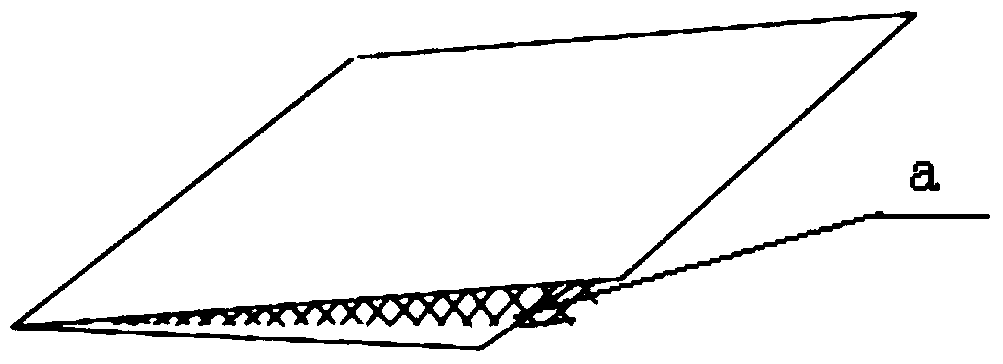

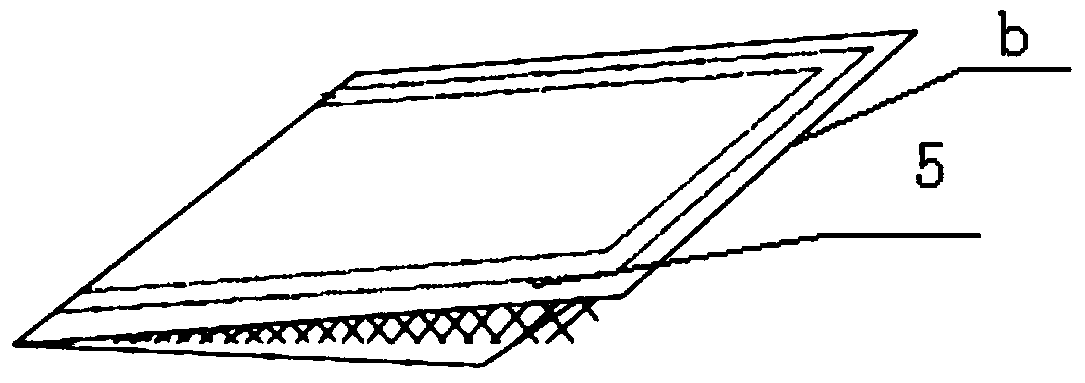

[0029] Step 1: Fold the two diaphragms in half to form a "v" shape after applying glue in the same direction, and fold the two "v" shapes end to end to form an "M" shape. In the "M" shape, two consecutive "V" A water separator is placed in the groove.

[0030] Step 2: Fold several un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com