Electronic beam physical vapor deposition method for large-area uniform deposition of thermal barrier coating layers

A technology of physical vapor deposition and thermal barrier coating, which is used in coatings, metal material coating processes, ion implantation plating, etc. Layer uniformity can not be guaranteed and other problems, to achieve the effect of uniform preparation, solve the preparation of uniform thermal barrier coating, and increase the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

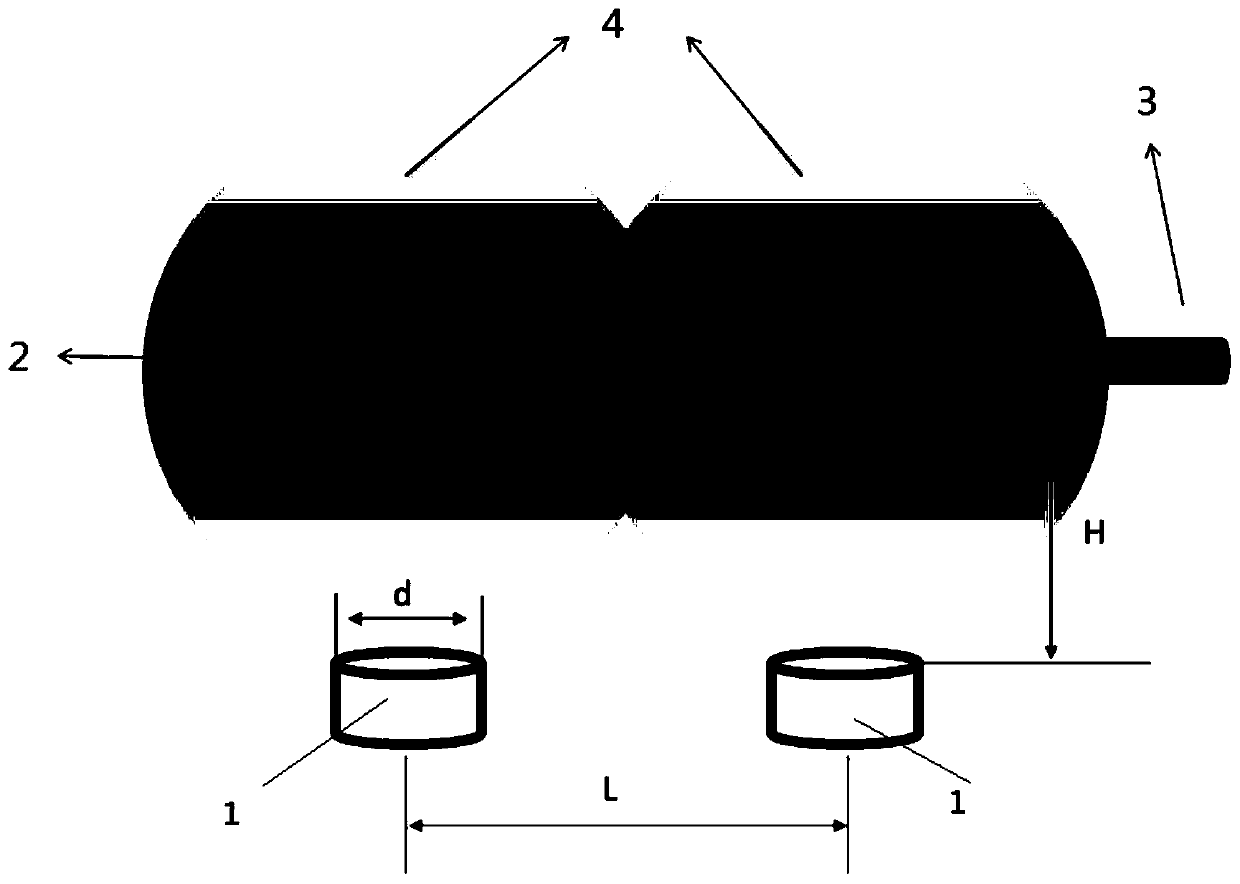

[0029] Such as figure 1 As shown, in this embodiment, two crucibles 1 are selected, the inner diameter d of the crucibles 1 is 60 mm, the distance L between the centers of the two crucibles 1 is 300 mm, and the vertical distance H between the crucible 1 and the workpiece 2 is 270 mm.

[0030] Sandblasting is performed on the surface of the workpiece 2, and the surface of the workpiece 2 is cleaned, and the workpiece 2 is fixed on the rotating shaft 3.

[0031] The workpiece 2 is heated to a temperature of 850°C.

[0032] The YSZ material in the evaporation crucible 1 is heated by the electron beam, and a stable vapor cloud 4 is formed above the middle of the two crucibles 1 .

[0033] The workpiece 2 is sent into the steam cloud 4 through the rotating shaft 3 for coating deposition, the rotation speed of the workpiece 2 is 10 rad / min, and the coating deposition time is 25 min.

[0034] After the coating is deposited, the electron beam is turned off, the vapor cloud 4 disappe...

Embodiment 2

[0036] Such as figure 1 As shown, in this embodiment, two crucibles 1 are selected, the inner diameter d of the crucibles 1 is 70 mm, the distance L between the centers of the two crucibles 1 is 600 mm, and the vertical distance H between the crucible 1 and the workpiece 2 is 660 mm.

[0037] Sandblasting is performed on the surface of the workpiece 2, and the surface of the workpiece 2 is cleaned, and the workpiece 2 is fixed on the rotating shaft 3.

[0038] The workpiece 2 is heated to a temperature of 1100°C.

[0039] The YSZ material in the evaporation crucible 1 is heated by the electron beam, and a stable vapor cloud 4 is formed above the middle of the two crucibles 1 .

[0040] The workpiece 2 is sent into the steam cloud 4 through the rotating shaft 3 for coating deposition, the rotation speed of the workpiece 2 is 25 rad / min, and the coating deposition time is 40 min.

[0041] After the coating is deposited, the electron beam is turned off, the vapor cloud 4 disapp...

Embodiment 3

[0043] Take the turbine blade of the engine, sandblast the surface of the blade, clean the surface of the blade and fix the blade on the rotating shaft 3 .

[0044] Such as figure 1 As shown, in this embodiment, two crucibles 1 are selected, the inner diameter d of the crucibles 1 is 50 mm, the distance L between the centers of the two crucibles 1 is 400 mm, and the vertical distance H between the crucibles 1 and the blades is 470 mm.

[0045] The blade is heated, and the heating temperature is up to 900°C.

[0046] The YSZ material in the evaporation crucible 1 is heated by the electron beam, and a stable vapor cloud 4 is formed above the middle of the two crucibles.

[0047] The blade is sent into the steam cloud 4 through the rotating shaft 3 to deposit the coating, the rotation speed of the blade is 10 rad / min, and the coating deposition time is 25 min.

[0048] After the coating is deposited, the electron beam is turned off, and the steam cloud 4 disappears, and the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com