Grinding equipment for preparing granule dispersion

A technology of dispersion and equipment, applied in the field of grinding equipment for preparing particle dispersion and grinding equipment, can solve the problems of low grinding efficiency, prolong downtime, and stop production of grinding equipment, so as to improve grinding efficiency, reduce clogging, and expand effective The effect of grinding the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in detail, but protection scope of the present invention is not limited to following embodiment, promptly all the simple equivalent changes and modifications that are done with the patent scope of the present invention and description content, All still belong to the scope covered by the patent of the present invention. For example, in the equipment shown in the drawings of the present invention, a cooling system is added to the outer wall of the grinding bucket to reduce the temperature of the material to be ground and improve the grinding efficiency.

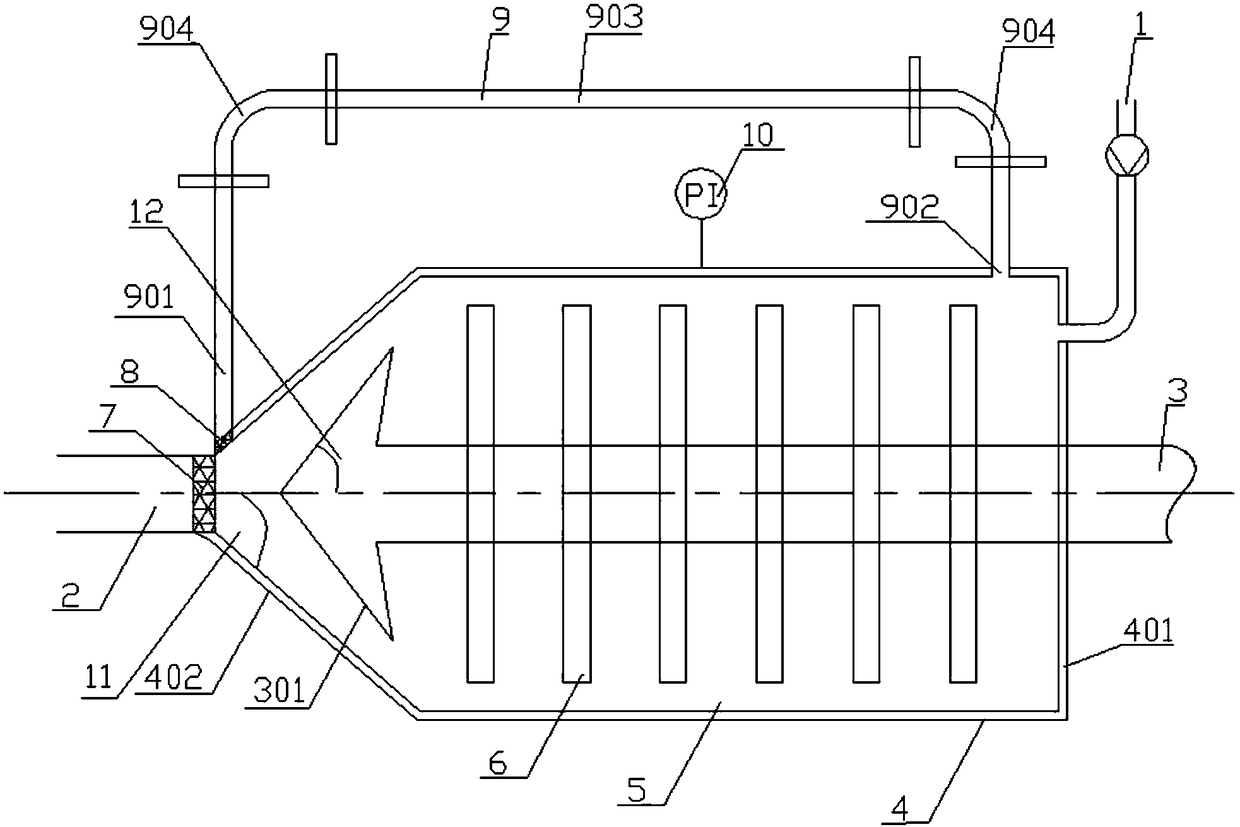

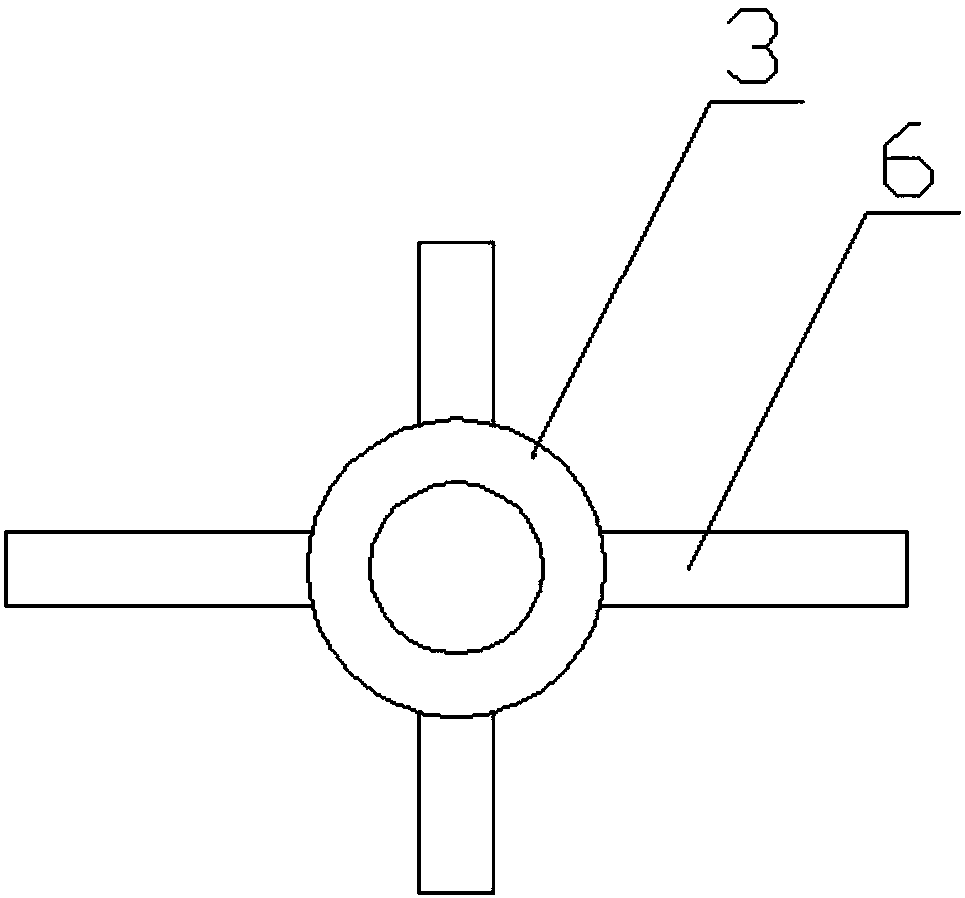

[0037] Such as figure 1 with figure 2 A kind of grinding equipment for the preparation of particle dispersion shown in , including feed inlet 1, discharge outlet 2, rotating shaft 3, grinding cylinder 4, grinding chamber 5, stirring blade 6, first separator 7, second Separator 8, return pipe 9 and pressure gauge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com