Fluorescent display tube

A fluorescent display tube and anode technology, applied in the field of fluorescent display tubes, can solve the problems of digital grid shape and complex combination, and achieve the effect of reducing the number of installation man-hours and high-density fluorescent display tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

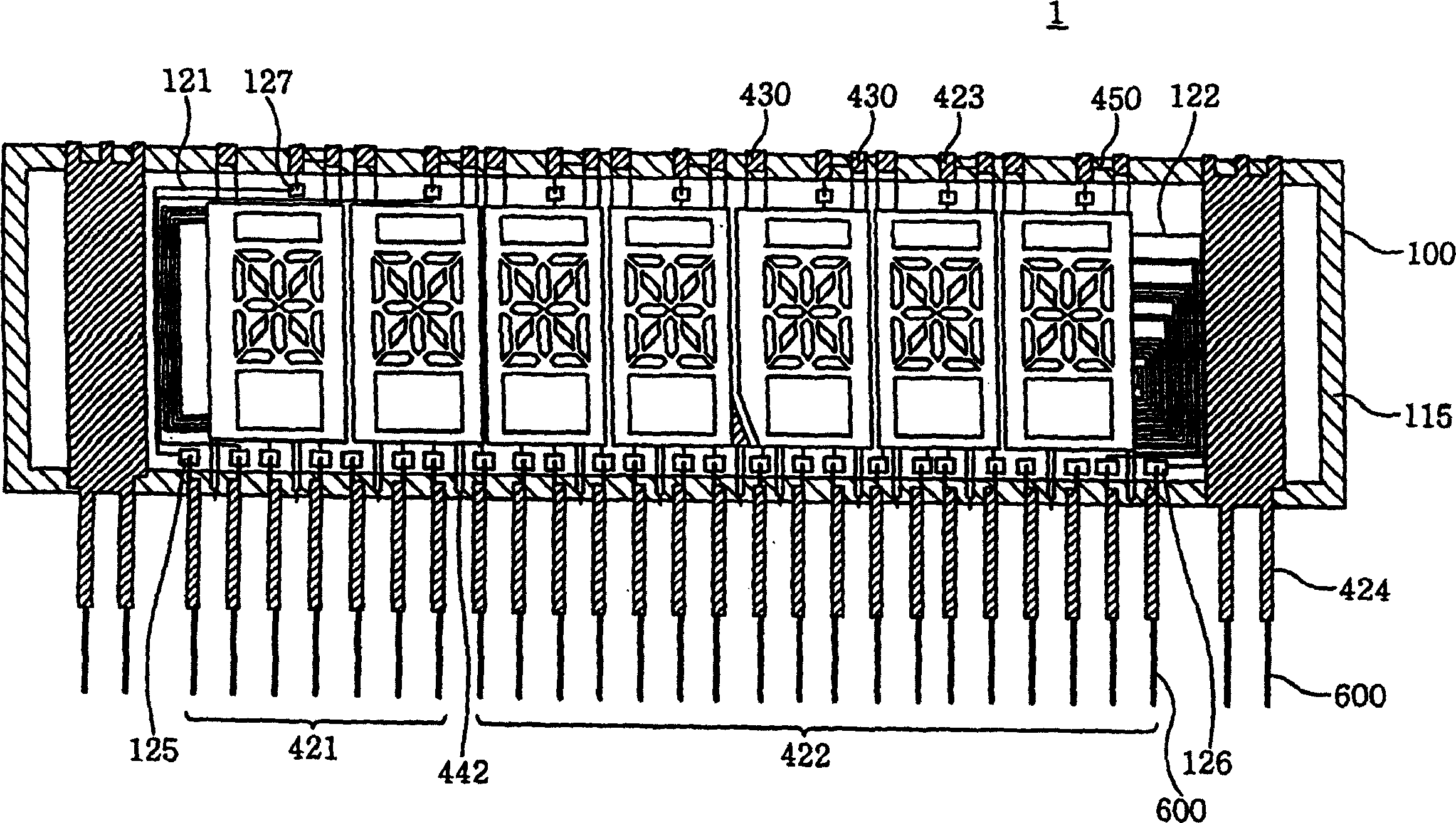

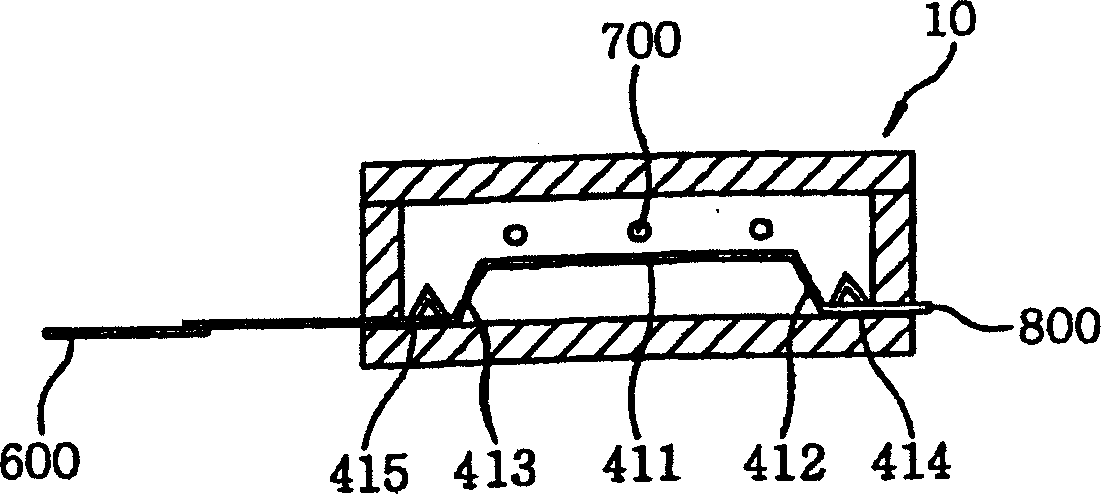

[0108] Below to Figure 1A-1D as well as figure 2 Based on this, the fluorescent display tube of the present invention will be described.

[0109] (Formation of anode substrate)

[0110] An aluminum film layer is arranged on the upper surface of an insulating substrate (110) made of soda-lime glass, and then a wiring layer is formed by photolithography, and the wiring layer includes: (i) gate wiring (121); (ii) ) electrically connecting the gate wiring (121) and the gate terminal A (127) of the gate (410); (iii) electrically connecting the gate for energizing the gate wiring (121) from the outside The grid terminal B (125) of the wire (421); (iv) the anode wiring (122); (v) the anode of the anode wire (422) electrically connected to the anode wiring (122) from the outside terminal (126).

[0111] Next, in order to cover the wiring layer, an insulating layer (130) is formed by using a paste mainly composed of low-melting glass and a pigment by a thick film printing method....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com