Methods of fabricating retroreflector prisms with polygonal apertures and devices thereof

A retroreflector and prism technology is applied in the field of manufacturing retroreflector prisms with polygonal apertures and devices thereof, and can solve problems such as being unsuitable for manufacturing retroreflecting prisms and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

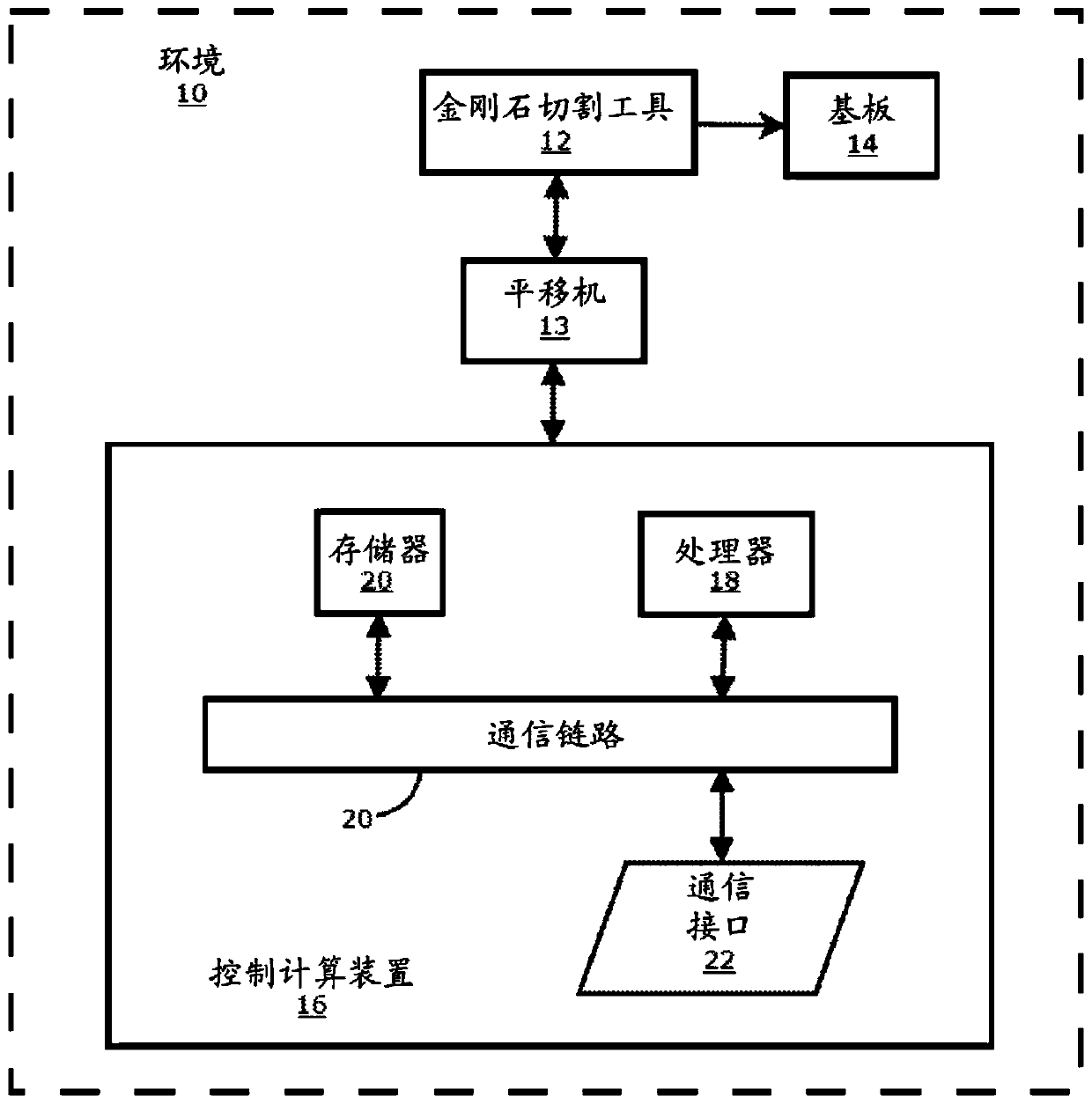

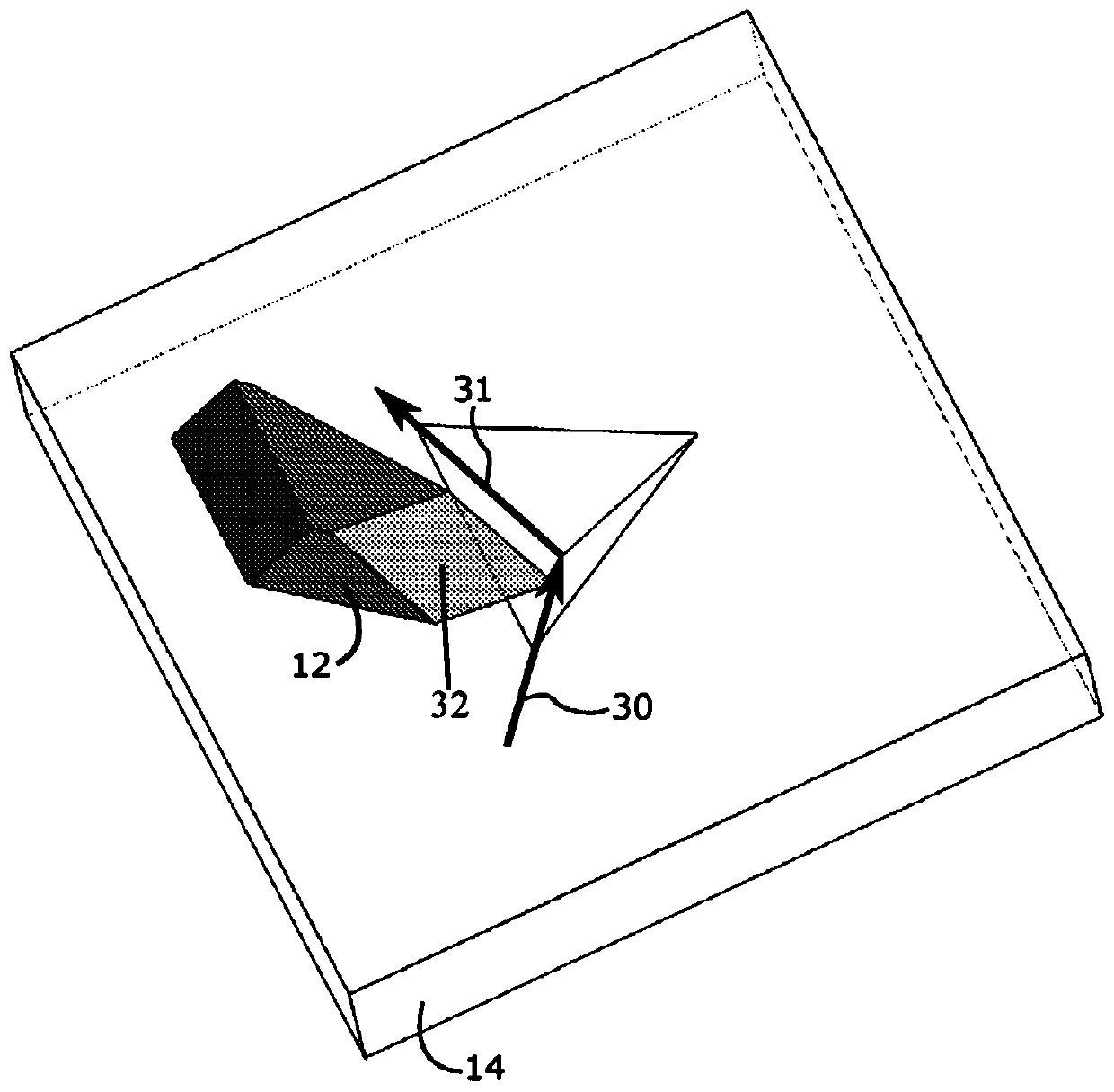

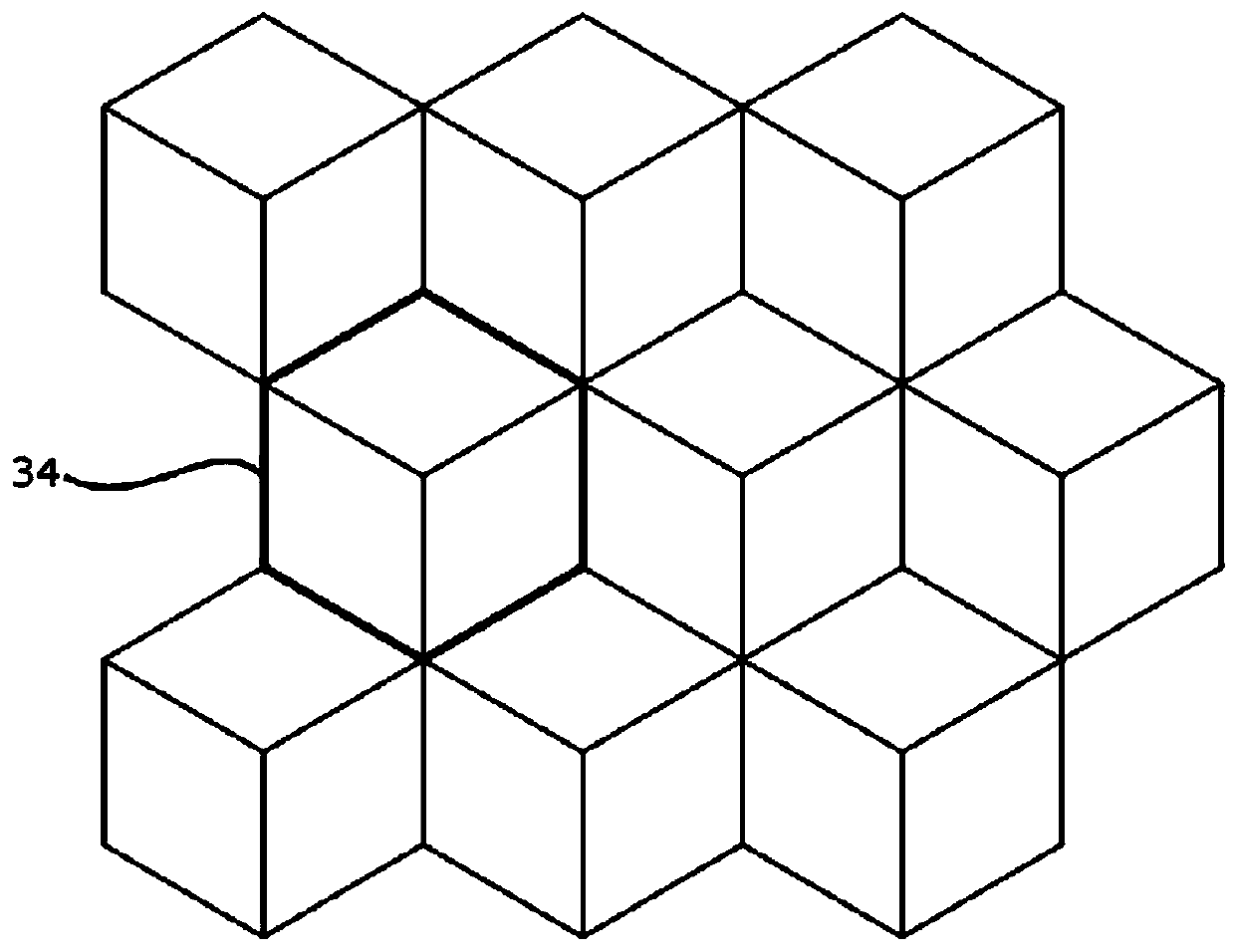

[0019] see figure 1 , shows an environment 10 for forming retroreflective prisms in a substrate that can be used to fabricate retroreflector molds and retroreflective sheeting using diamond microgouge. Diamond microchiseling (DMC) is a process in which a multi-axis high-precision machine tool cuts diamonds in and out through a substrate to remove material, such as "Diamond MicroChiseling of Large-Scale Retroreflective Arrays" by Brinksmeier et al. (Precision Engineering, 2012, p. 34, No. 4, pp. 650-57), the disclosure of which is hereby incorporated by reference in its entirety. DMC advantageously provides a method for producing retroreflector molds that include polygonal or other similarly shaped retroreflective prisms that cannot be produced using conventional fly-cut techniques. DMC also provides enhanced flexibility in retroreflector design. DMC allows the production of polygonal retroreflectors with increased effective area that meet various global specifications for su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com