Membrane stack and electro-desalting assembly

An electric desalination and membrane stack technology, applied in the field of membrane stacks and electric desalination components, can solve the problem of the need to improve the desalination efficiency, and achieve the effects of strong hardness tolerance, enhanced mass transfer process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in further detail below in conjunction with the accompanying drawings.

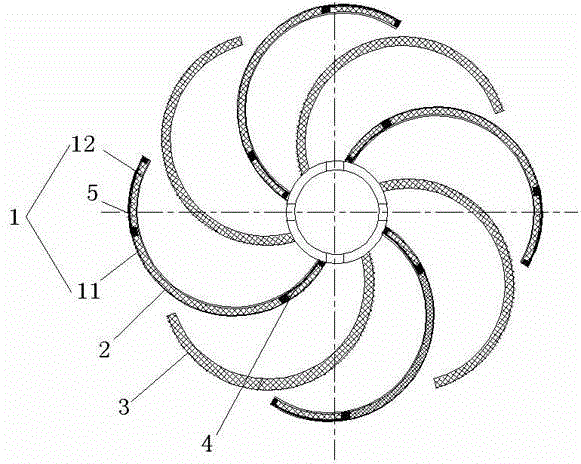

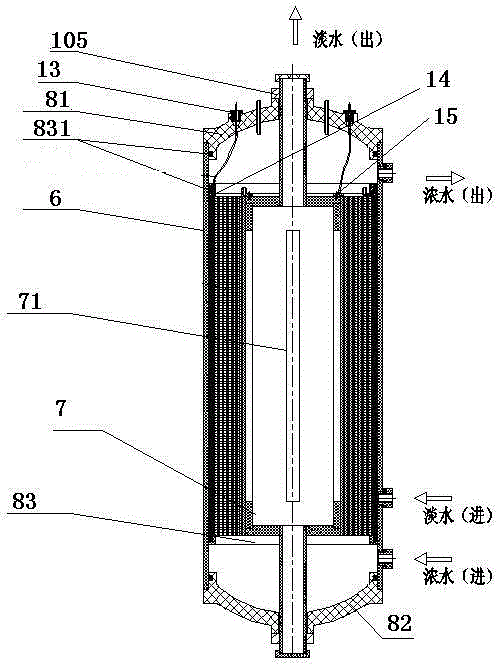

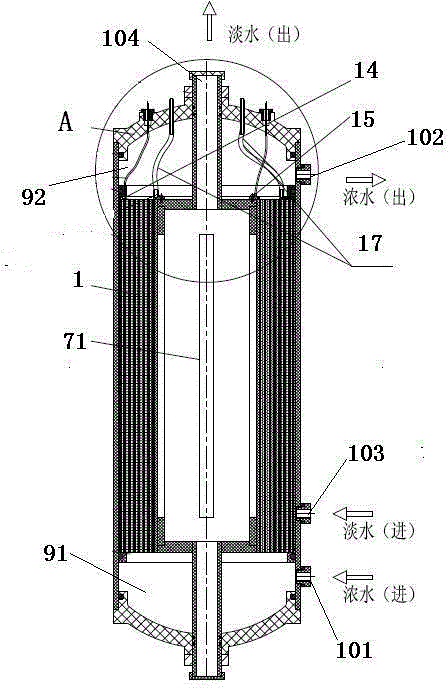

[0069] Such as Figure 1-Figure 10 As shown, the membrane stack includes several membrane bags 1, concentrated water grids 2 and fresh water grids 3, each membrane bag 1 includes an anion exchange membrane 11 and a cation exchange membrane 12; the concentrated water grid 2 is arranged on the anion exchange Between the membrane 11 and the cation exchange membrane 12; the fresh water grid 3 is arranged between two adjacent membrane bags 1; the two ends of the membrane bag 1 are provided with a first electrode sheet 4 and a second electrode sheet 5 for forming an electric field; The length of the first electrode sheet 4 or the second electrode sheet 5 is smaller than the length of the anion exchange membrane 11 or the cation exchange membrane 12 . The first electrode sheet 4 and the second electrode sheet 5 are arranged on the opposite inner side of the anion e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com