Method for preparing rehmanniae flavor for cigarette by using membrane separation technique

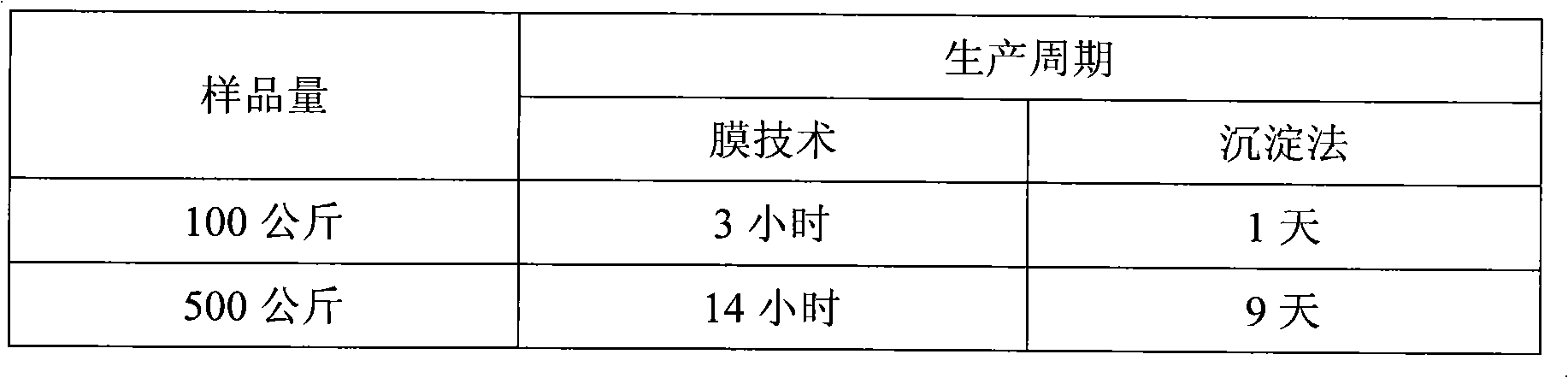

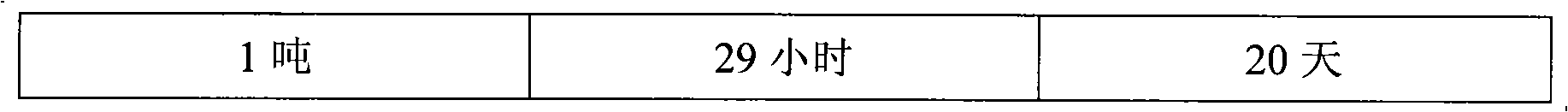

A technology for tobacco flavor and membrane separation, which is applied in the directions of essential oil/spice, membrane technology, semi-permeable membrane separation, etc., can solve the problems of complex production process, long production cycle and high production cost, and achieves simple process and short production cycle. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) After grinding rehmannia glutinosa into powder, take 1 times the weight of rehmannia glutinosa, add 6 times the weight of 40% (volume percentage) ethanol solution, reflux extraction at 120° C. for 3-5 hours, and filter.

[0036] (2) Add 40% (volume percentage) ethanol solution of 6 times the weight of the original medicinal material to the remaining filter residue after step (1) is filtered, continue the reflux extraction at a temperature of 120°C for 4 hours, filter and combine the two The filtrate was obtained to obtain Rehmannia glutinosa extract A.

[0037] (3) First pass the Rehmannia glutinosa extract A through a ceramic membrane with a pore size of 100nm (first-stage membrane), the flow rate is 65L / h, the temperature is controlled below 45°C, the inlet pressure is 2.0MPa, and the outlet pressure is 1.2MPa. When the rehmannia extract A system starts to foam, add 10% water of the total weight of the rehmannia extract to increase the yield of the target product....

Embodiment 2

[0041] (1) After grinding the dried Rehmannia glutinosa into powder, take 1 times the weight of Rehmannia glutinosa, add 8 times the weight of 50% (volume percentage) ethanol solution, reflux extraction at 120° C. for 4 hours, and filter.

[0042] (2) Add 50% (volume percentage) ethanol solution of 8 times the weight of the original medicinal material to the remaining filter residue after step (1) is filtered, continue the reflux extraction at a temperature of 120°C for 4 hours, filter and combine the two The filtrate was obtained to obtain Rehmannia glutinosa extract A.

[0043] (3) First pass the Rehmannia glutinosa extract A through a ceramic membrane with a pore size of 100nm (first-stage membrane), the flow rate is 65L / h, the temperature is controlled below 45°C, the inlet pressure is 2.0MPa, and the outlet pressure is 1.2MPa. When the rehmannia extract A system starts to foam, add 15% water of the total weight of the rehmannia extract to increase the yield of the target ...

Embodiment 3

[0047] (1) After grinding the mixture of rehmannia glutinosa and fresh rehmannia glutinosa into powder, take 1 times the weight of rehmannia glutinosa, add 10 times the weight of 60% (volume percentage) ethanol solution, and extract under reflux at 120°C for 4 hours ,filter.

[0048] (2) Add 60% (volume percentage) ethanol solution of 10 times the weight of the original medicinal material to the remaining filter residue after step (1) is filtered, continue to reflux and extract for 4 hours at a temperature of 120° C., filter and combine the two The filtrate was obtained to obtain Rehmannia glutinosa extract A.

[0049] (3) First pass the Rehmannia glutinosa extract A through a ceramic membrane with a pore size of 100nm (first-stage membrane), the flow rate is 65L / h, the temperature is controlled below 45°C, the inlet pressure is 2.0MPa, and the outlet pressure is 1.2MPa. When the rehmannia extract A system starts to foam, add 20% water of the total weight of the rehmannia ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com