Spiral wound membrane component and membrane processor adopting spiral wound membrane component

A technology of membrane processor and roll membrane, which is applied in the direction of osmosis/dialysis water/sewage treatment, membrane, membrane technology, etc. It can solve the problems of large space occupation, long time required, waste of energy, etc., and achieves convenient assembly, The effect of reducing the required time and reducing the amount of water stored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

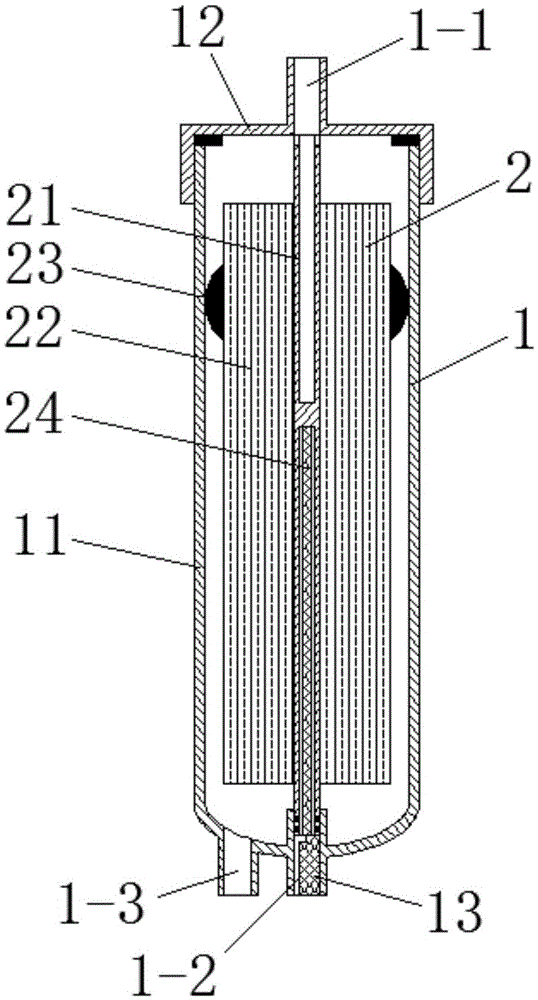

[0019] See figure 1 , the membrane processor of this embodiment includes a casing 1 and a roll-type membrane module 2 arranged in the casing 1 .

[0020] The casing 1 is provided with a water inlet 1-1, a produced water outlet 1-2 and a concentrated water outlet 1-3. The housing 1 includes a cylinder body 11 and an end cap 12 . The end cap 12 is sealed and fixedly connected with the cylinder body 11 . The water inlet 1 - 1 of the shell 1 is arranged on the end cover 12 , and the produced water outlet 1 - 2 and the concentrated water outlet 1 - 3 are arranged on the cylinder body 11 . The produced water outlet 1-2 of the casing 1 is provided with a second filling block 13 that does not block the produced water outlet 1-2, or the inner diameter of the produced water outlet 1-2 is not greater than 5 mm. When the second filling block 13 is set in the water production outlet 1-2 of the housing 1, the water flow channel in the water production outlet 1-2 is set in the second fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com