Manufacturing method for high pumping concrete

A manufacturing method and concrete technology, applied in the field of engineering and building materials, can solve the problems of difficult pumping construction, high cost, high viscosity, etc., and achieve the effects of saving energy and resources, low manufacturing cost, and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Weigh concrete raw materials according to the following mass percentages:

[0054] Portland cement 23

[0055] Superfine powder 11

[0056] River sand or washed sea sand 28

[0057] Gravel 32

[0058] water 5

[0059] Water reducer 1;

[0060] (2) Pour the weighed Portland cement and superfine powder into the mixer, and stir for 40 seconds; add the weighed river sand or washed sea sand, and stir for 40 seconds; pour in the weighed water and water reducing agent, After stirring for 50 seconds, pour the weighed crushed stone, and after stirring for 70 seconds, concrete is obtained.

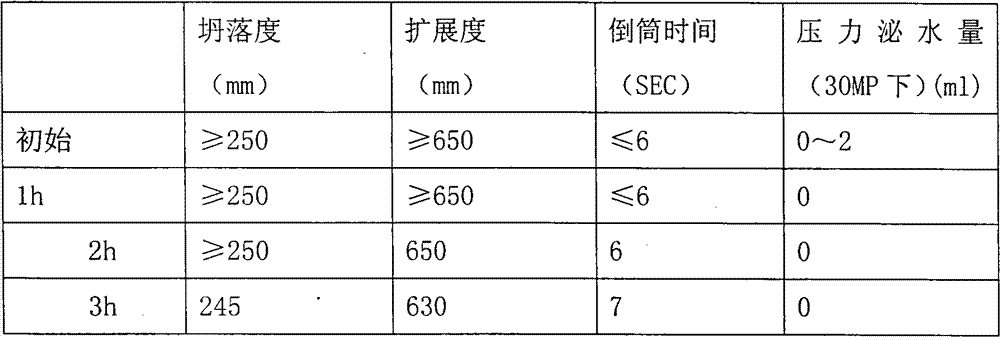

[0061] The concrete manufactured in the above-mentioned Example 1 was divided into two parts, one part was sealed and stored indoors, and the other part was sealed and stored under sunlight at 35°C. After 1 hour, 2 hours, and 3 hours, the slump, expansion, and Rewinding time and pressure bleeding volume, the results are as follows:

[0062]

[0063] After 3 hours, the plastic re...

Embodiment 2

[0068] (1) Weigh concrete raw materials according to the following mass percentages:

[0069] Portland cement 24

[0070] Superfine powder 10

[0071] River sand or washed sea sand 27

[0072] Gravel 33

[0073] water 4.8

[0074] Water reducer 1.2;

[0075] (2) Pour the weighed Portland cement and superfine powder into the mixer, and stir for 40 seconds; add the weighed river sand or washed sea sand, and stir for 40 seconds; pour in the weighed water and water reducing agent, After stirring for 50 seconds, pour the weighed crushed stone, and after stirring for 70 seconds, concrete is obtained.

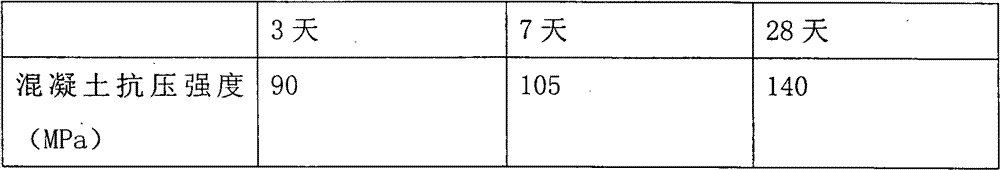

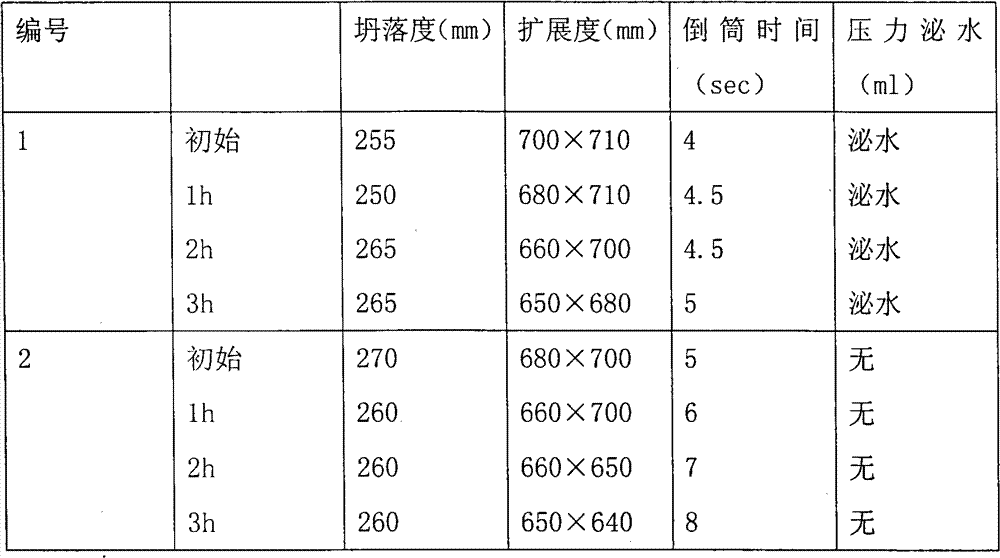

[0076] The ultra-high-performance concrete manufactured in Example 2 was compared with the concrete formulated with polycarboxylate superplasticizer. The performance of concrete is shown in Table-1, and the strength of concrete is shown in Table-2. No. 1 is the concrete prepared by polycarboxylate superplasticizer, in which the solid content of polycarboxylate superplasticizer i...

Embodiment 3

[0084] (1) Weigh concrete raw materials according to the following mass percentages:

[0085] Portland cement 23

[0086] Micro powder 9

[0087] River sand or washed sea sand 28

[0088] Gravel 34

[0089] water 4.5

[0090] Water reducer 1.5;

[0091] (2) Pour the weighed Portland cement and superfine powder into the mixer, and stir for 60 seconds; add the weighed river sand or washed sea sand, and stir for 50 seconds; pour in the weighed water and water reducer, After stirring for 70 seconds, pour the weighed crushed stone, and after stirring for 80 seconds, concrete is obtained.

[0092] In each of the above-mentioned embodiments, the preparation method of the water reducing agent used is as follows:

[0093] The water reducer is composed of A component and B component, the mass ratio of A component and B component is: A component: B component = 1: 1.5, where:

[0094] The mass percent of each raw material in A component is:

[0095] Naphthalene superplasticizer 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com