Rapid saturated steam generating device for steaming box

A fast-generating, steaming box technology, applied in the directions of steam generation, steam generation methods, lighting and heating equipment, etc., can solve the problems of uneven steaming, saturated steam distribution and temperature distribution, and fabric penetration, etc., to ensure Product quality, the effect of promoting rapid bleaching, and promoting uniform penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

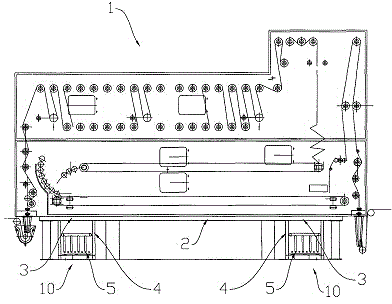

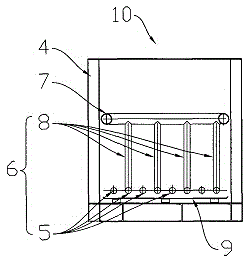

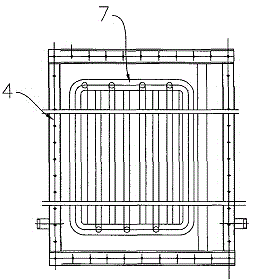

[0014] Such as figure 1 , 2 , 3, the steaming box saturated steam fast generating device of the present invention, its basic concept is: at the bottom 2 of the steaming box 1, offer at least one channel 3 (such as figure 1 There are two passages shown), corresponding to the passage 3, there is a tank 4 that is lower than the bottom 2 of the steam box, and a steam outlet (not shown in the figure) is installed at the lower part of the tank 4. Steam jacket 5 (for double pipe), described steam jacket 5 is connected to the outside of tank body 4 through steam inlet pipe 6. That is, at least one channel is opened at the bottom 2 of the steam box 1, and the corresponding channel connection is lower than the bottom of the steam box. The saturated steam fast generating device 10 is used to rapidly heat the steaming box 1 through the saturated steam fast generating device 10 to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com