Method capable of reducing water leakage of water closet

A technology for toilets and toilets, which is applied to flushing equipment with water tanks, water supply devices, buildings, etc., and can solve the problems of long leakage time, inevitable water leakage, failure, and water overflowing from overflow pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

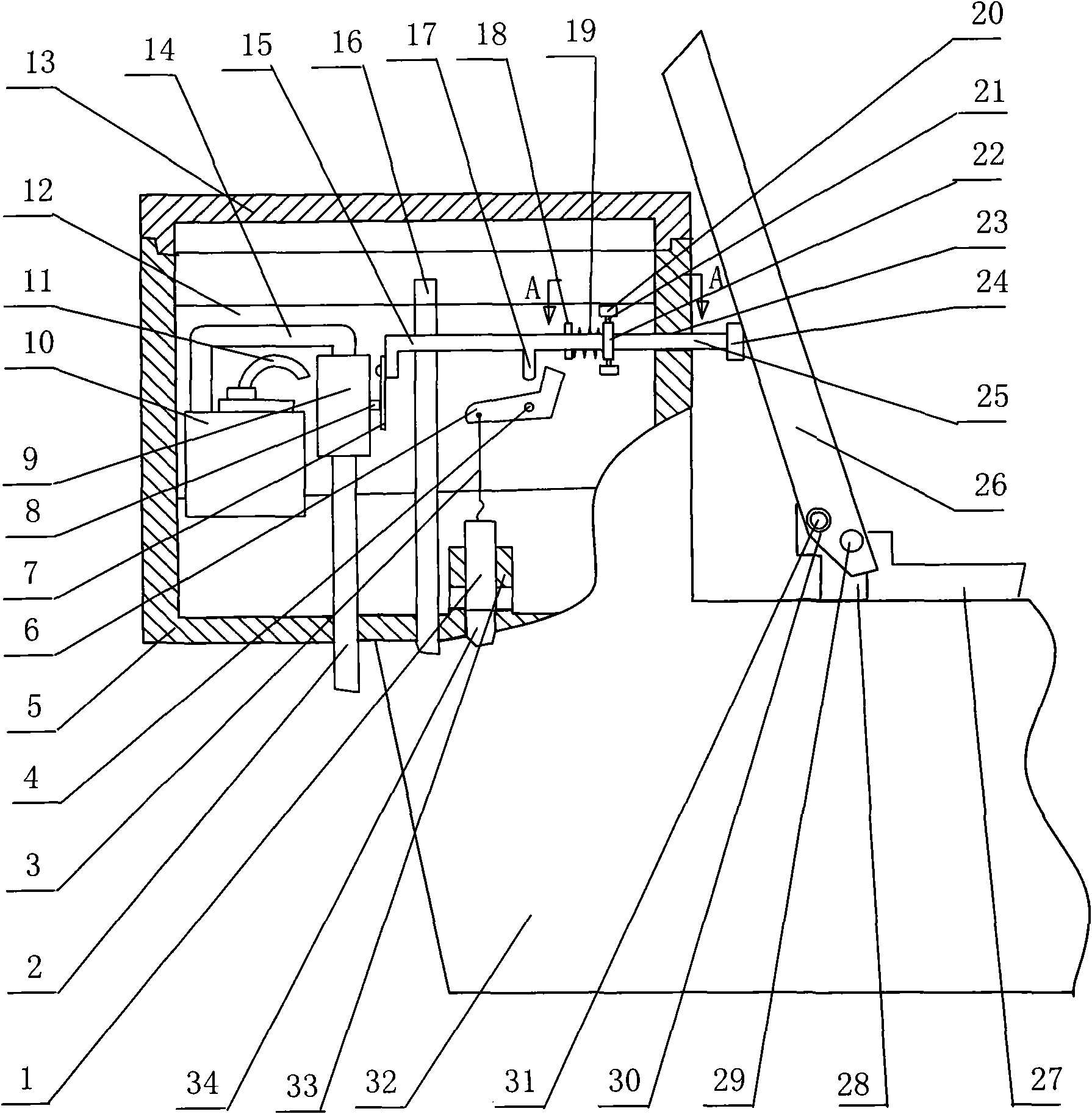

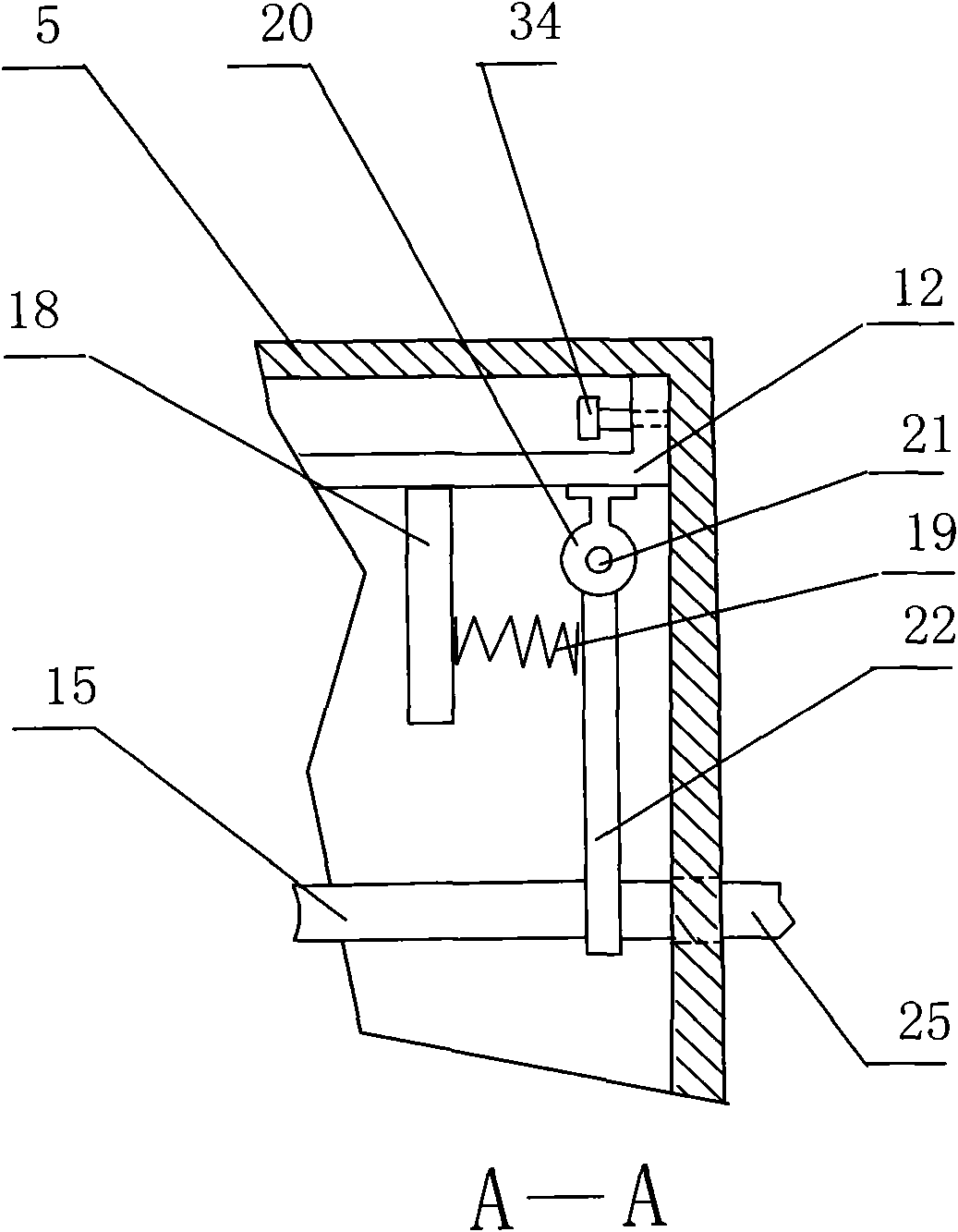

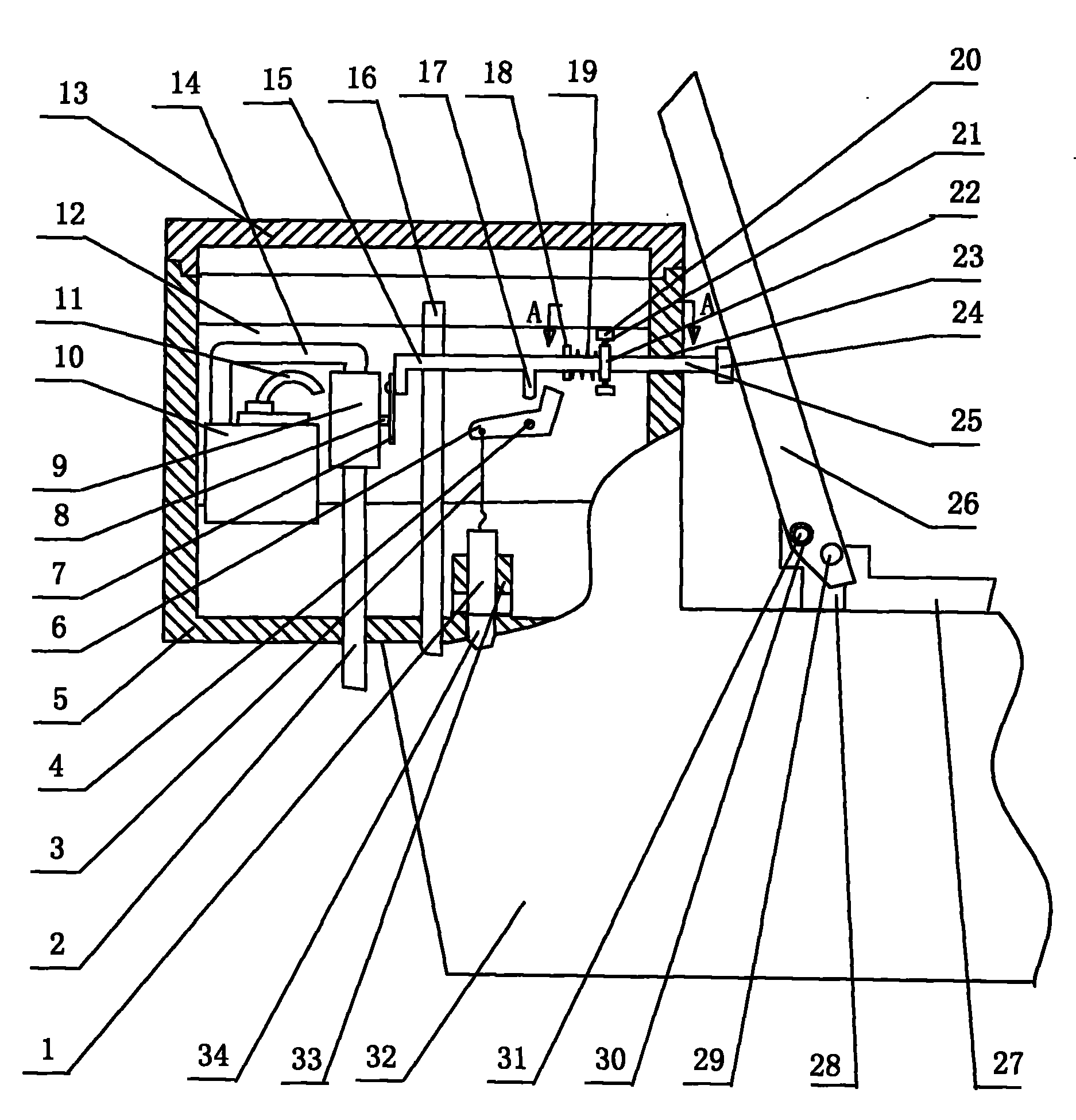

[0008] figure 1 1 is the flush valve column, 2 is the water inlet pipe of the micro-motion inlet valve, 3 is the pull wire of the flush valve column, 4 is the thread lifter shaft, 5 is the water tank, 6 is the flush valve thread lifter, and 7 is the Working rod reed, 8 is the micro-motion water inlet valve contact, 9 is the micro-motion water inlet valve, 10 is the buoyancy valve, 11 is the water outlet pipe of the buoyancy valve, 12 is the bracket, 13 is the water tank cover, 14 is the micro-motion water inlet The connecting pipe between the valve outlet and the water inlet of the buoyancy valve, 15 is the working rod, 16 is the overflow pipe, 17 is the push head of the working rod, 18 is the pressing spring bar, 19 is the pressing spring, 20 is the hole seat of the rotating shaft, and 21 is the rotating shaft. Axle, 22 is a rotating rod, 23 is a water tank push rod hole, 24 is a push rod head, 25 is a push rod (it stretches out of the water tank), 26 is a toilet cover, 27 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com