Abrasion-resistant, high-temperature, and high-pressure resistant flexible water pipes for long-distance extinguishing of mountain fires on transmission lines

A power transmission line, long-distance technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems that cannot meet the needs of long-distance fire extinguishing, inconvenient storage of water pipes, low utilization rate of fire water, etc., to achieve Improve mechanical properties and service life, facilitate storage and arrangement, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

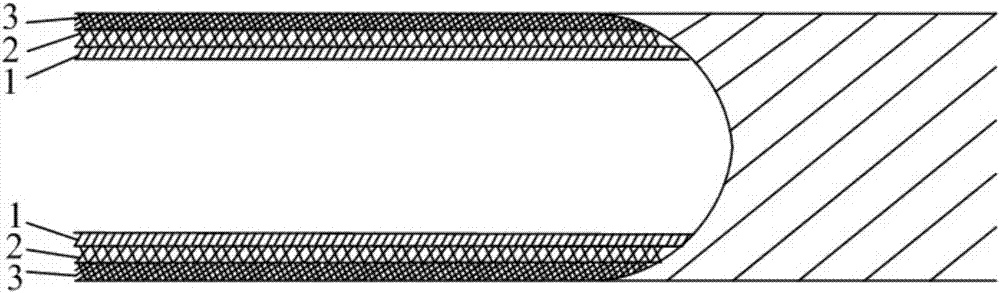

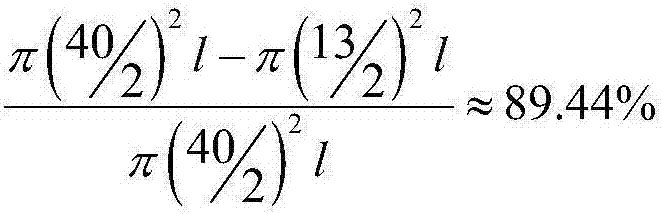

Image

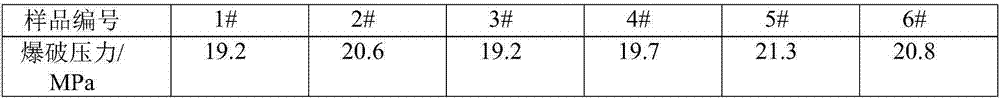

Examples

Embodiment 1

[0027] The preparation of embodiment 1 polyurethane-PVC composite material

[0028] This embodiment is made of 16% (mass) polyester thermoplastic polyurethane, 70% PVC material, 10% DOP, 2% dibutyltin dilaurate heat stabilizer, and 2% anhydrous copper sulfate.

[0029] The preparation method of polyurethane-PVC composite material is:

[0030] 1) Pre-plasticization of PVC: when pre-plasticizing, first mix 70 parts (by weight) of PVC material, 10 parts of DOP, 2 parts of dibutyltin dilaurate and 2 parts of anhydrous copper sulfate into the oven, Pre-plasticize at 100°C for 15-20 minutes. During the pre-plasticization process, the material should be taken out of the oven and stirred every 5 minutes or so.

[0031] 2) Preparation of PVC / TPU (thermoplastic polyurethane elastomer) blend: Weigh 16 parts of thermoplastic polyurethane according to the formula, and vacuum-dry it in an oven at 60-80° C. for 5-8 hours. Put the dried 16 parts of thermoplastic polyurethane and 84 parts o...

Embodiment 2

[0034] The preparation of embodiment 2 polyurethane-PVC composite material

[0035] This embodiment is made by compounding 20 parts (mass) of thermoplastic polyurethane, 65 parts of PVC material, 8 parts of DOP, 5 parts of dibutyltin dilaurate heat stabilizer, and 2 parts of anhydrous copper sulfate.

[0036] The preparation method of the polyurethane-PVC composite material of this example is the same as that of Example 1 except for the amount of each component added.

Embodiment 3

[0037] The preparation of embodiment 3 polyurethane-PVC composite material

[0038] This embodiment is made by compounding 18 parts (mass) of thermoplastic polyurethane, 68 parts of PVC material, 12 parts of DOP, 1 part of dibutyltin dilaurate heat stabilizer, and 1 part of anhydrous copper chloride.

[0039] The preparation method of the polyurethane-PVC composite material of this example is the same as that of Example 1 except for the amount of each component added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com