Equipment for dyeing and finishing polyester fibre flat woven tape

A webbing and flat technology, applied in the field of polyester flat webbing dyeing and finishing equipment, can solve the problems of uneven thickness of polyester webbing, affecting the color and luster of polyester webbing, deformation of polyester flat webbing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

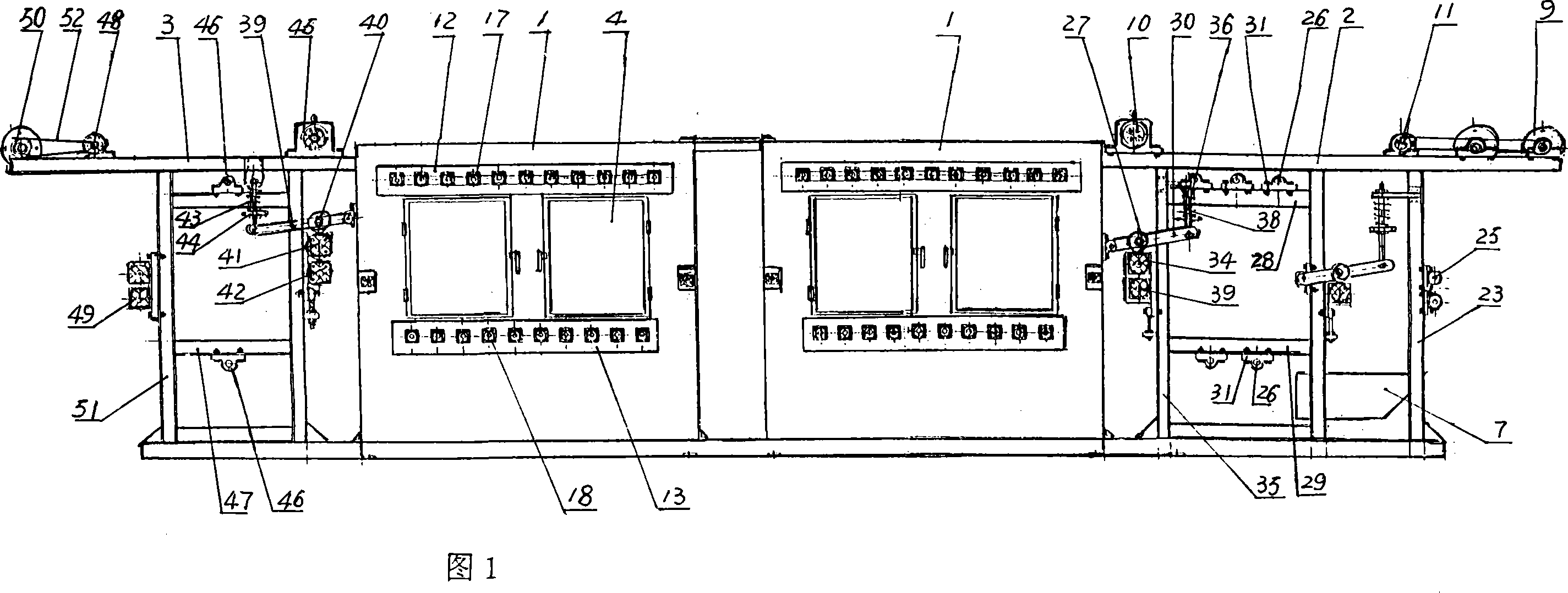

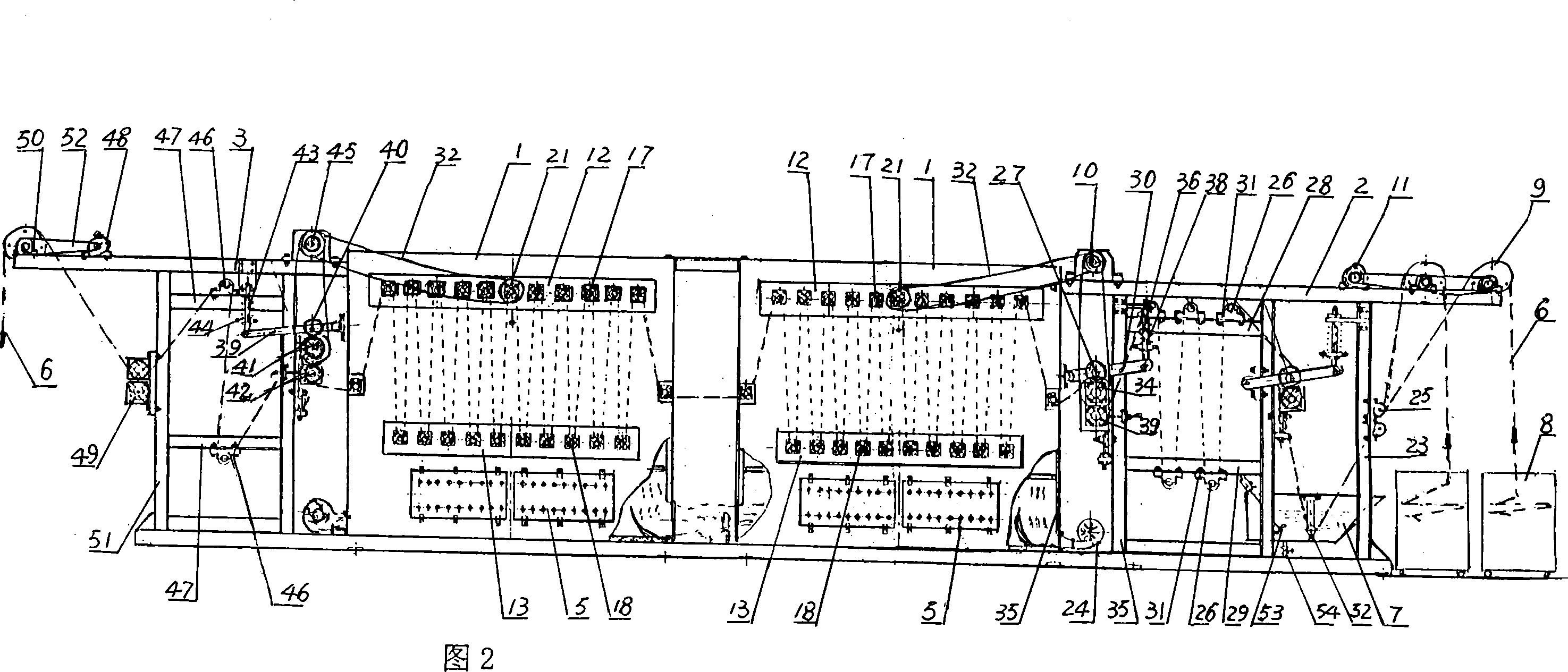

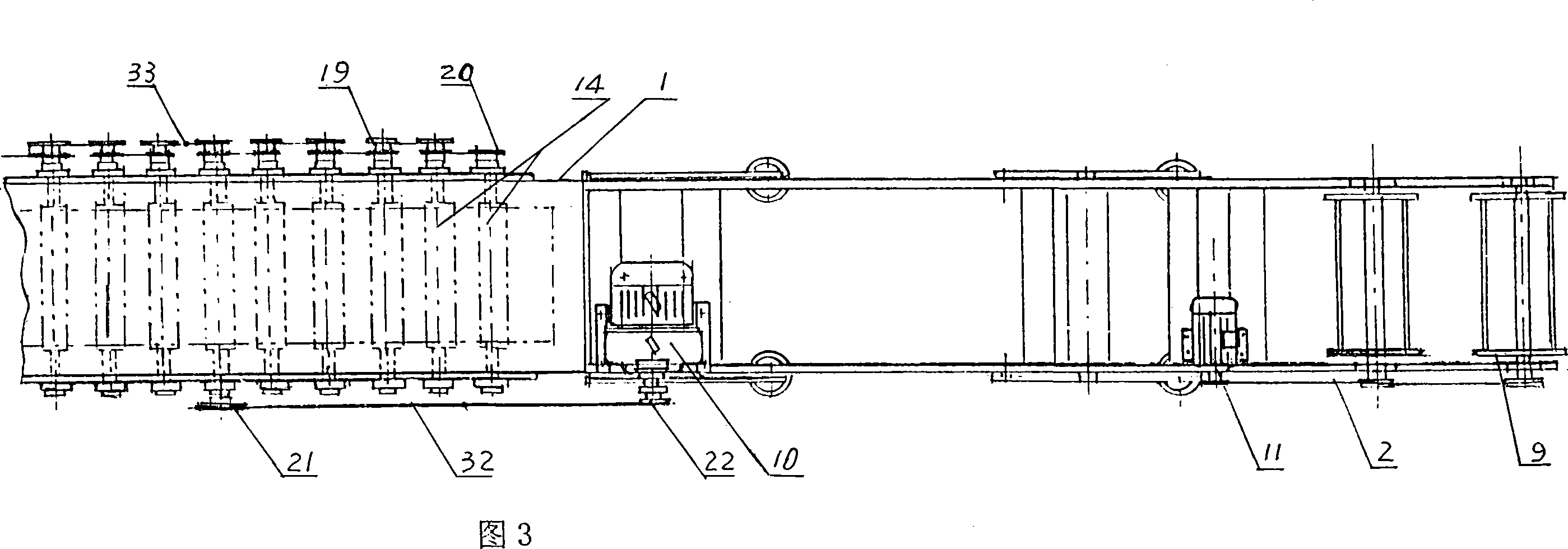

[0022] Referring to accompanying drawings 1 to 4, the polyester flat ribbon dyeing and finishing equipment consists of a front tension frame 2, a rear tension frame 3, a belt unscrambling device, a dyeing tank 7, a front traction extrusion mechanism, a drying box 1, a rear traction mechanism, a cooling mechanism, The composition of the tape-out mechanism. The front tension frame 2 is contained in the front portion of the drying box 1, and the rear tension frame 3 is contained in the rear portion of the drying box 1. The belt arrangement device includes a webbing trolley 8, a squirrel cage type belt arrangement roller 9, a reduction motor 11, and a belt arrangement device. Belt rollers, the ribbon transport trolley 8 is placed below the front tension frame 2, and the squirrel cage type belt unscrambling roller 9 is installed above the front tension frame 2. There can be 1 to 3 squirrel cage type belt unscrambling rollers 9, and the deceleration Motor 11 is contained on the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com