Environment-friendly cloth drying device

A cloth drying and environmental protection technology, applied in drying, drying machines, heating devices, etc., can solve the problems of low drying efficiency of cloth, environmental pollution, health impact of workers, etc., to improve environmental protection, reduce production costs, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

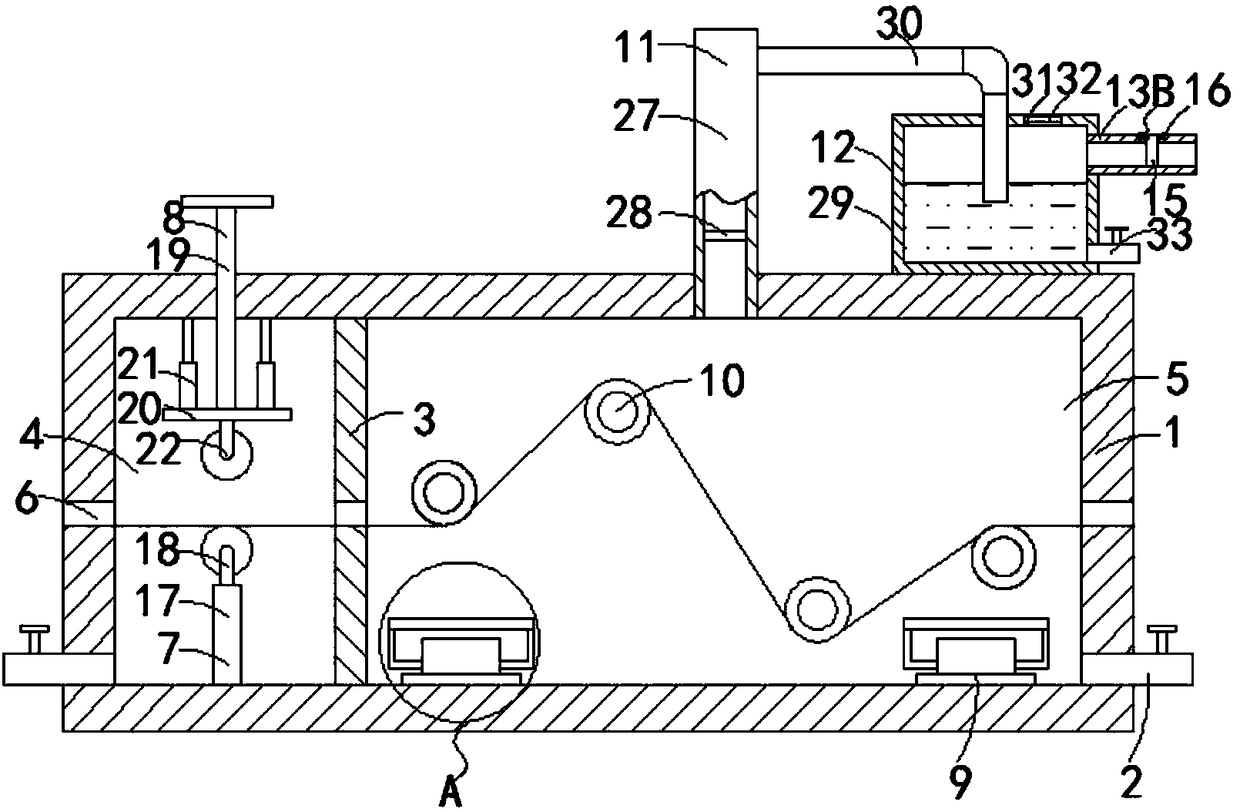

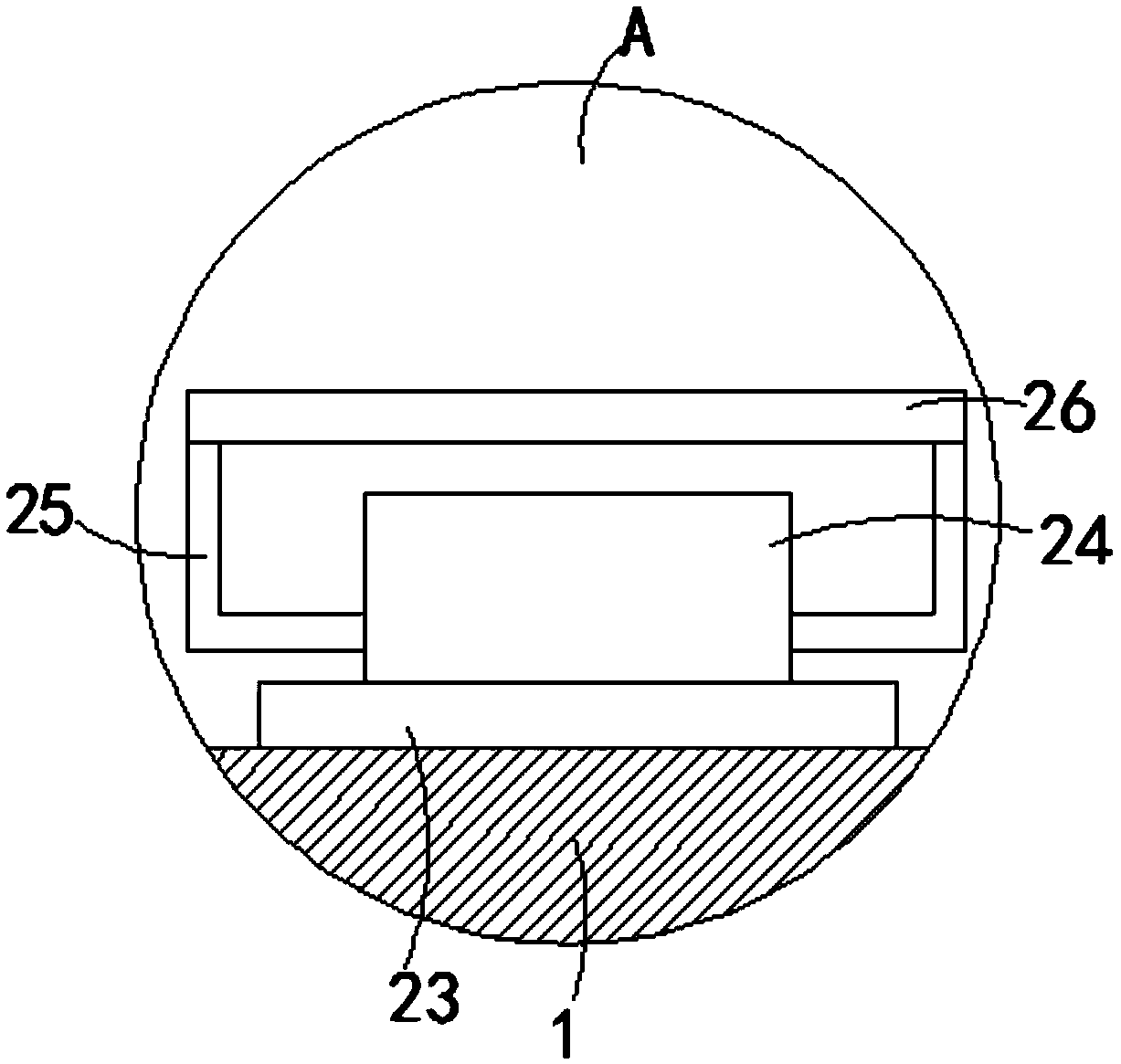

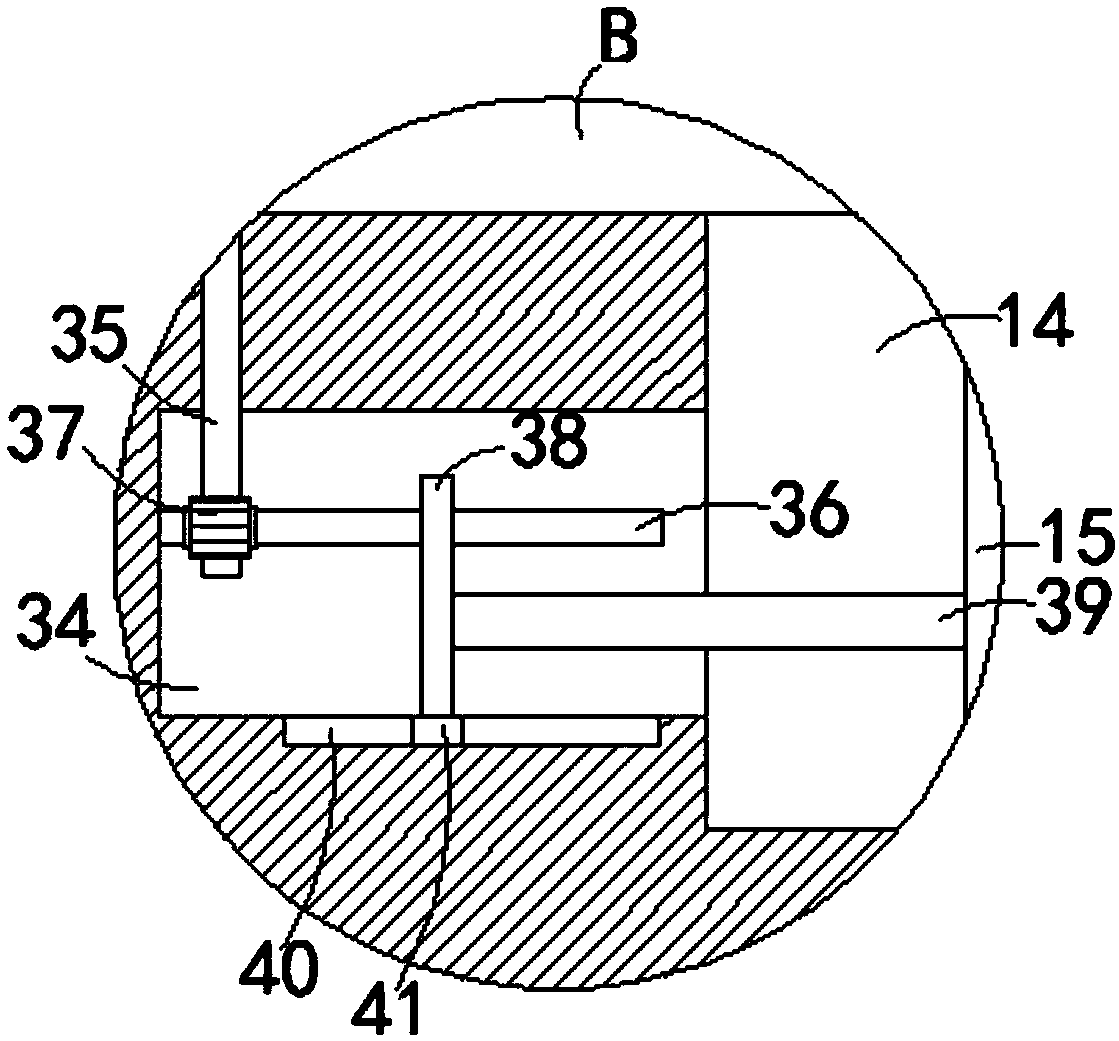

[0021] Such as Figure 1-4 As shown, an environment-friendly cloth drying device includes a drying box 1, a plurality of first drain pipes 2 are connected to the side walls of the left and right ends of the drying box 1, and the first liquid drain pipes 2 are installed with trapping first A flow control valve is convenient to control the discharge of liquid in the drying box 1. The drying box 1 is vertically provided with a partition plate 3, and the upper and lower ends of the partition plate 3 are respectively fixed to the top surface and the bottom of the drying box 1. connected, the partition plate 3 separates the drying box 1 into a dehydration chamber 4 and a drying chamber 5, and the inner walls of the left and right ends of the dehydration chamber 4 and the drying chamber 5 are all provided with cloth openings 6, and the bottom of the dehydration chamber 4 is provided with There is a lower extruding device 7, an upper extruding device 8 is provided on the top surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com