Spool assembly

a technology of spools and parts, applied in the direction of transportation and packaging, textiles, papermaking, etc., can solve the problems of unsuitable wrinkles, defective parts of flexible sheet-like materials, and creases, etc., to achieve the effect of reducing the number of spools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

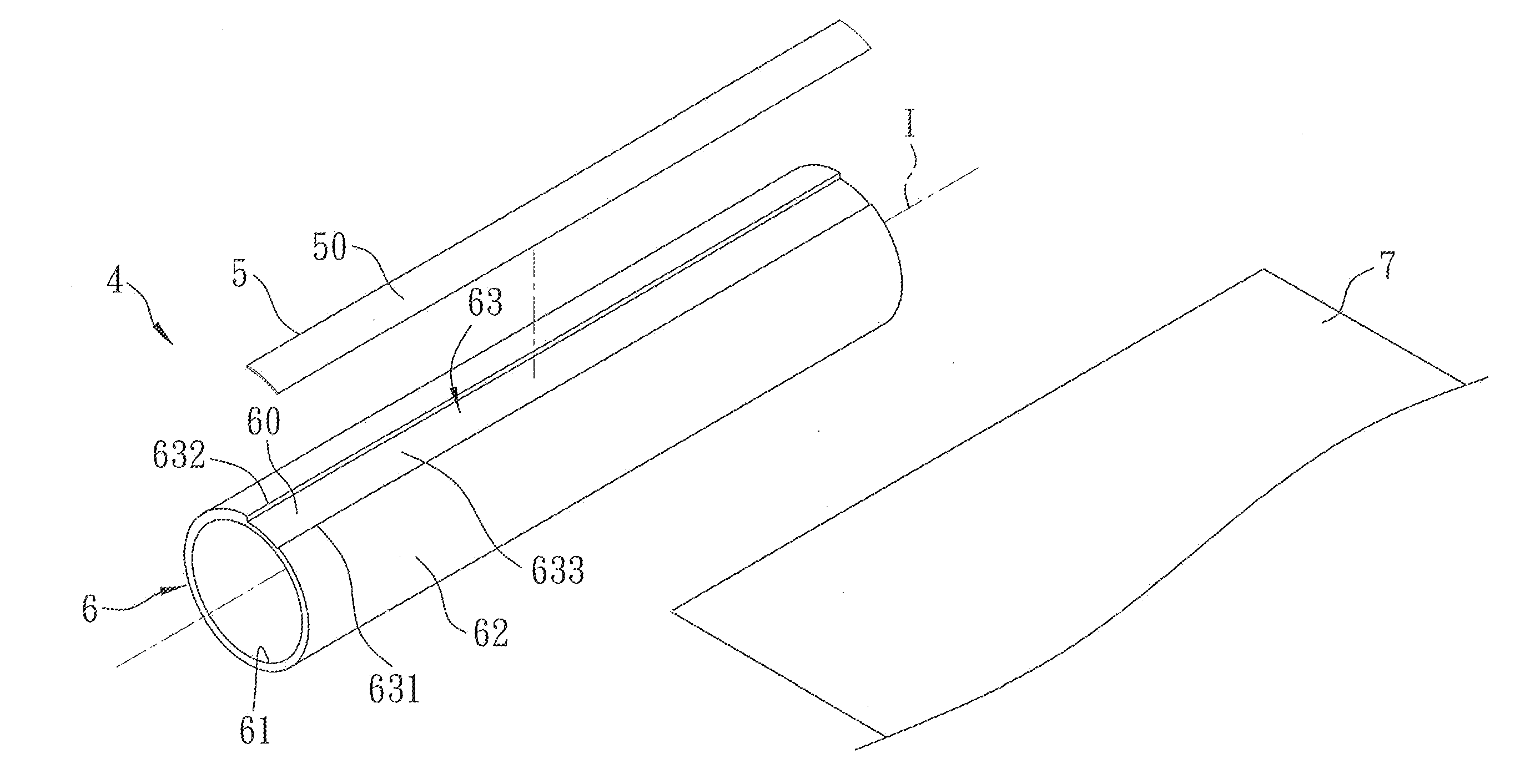

[0019]Referring to FIG. 5, the preferred embodiment of a spool assembly 4 for winding a flexible sheet-like material 7 thereon according to this invention is shown to include a tubular hub body 6 and a securing member 5.

[0020]The flexible sheet-like material 7 may be, for example, a fabric or an automobile tinted window film, and has a uniform thickness.

[0021]The tubular hub body 6 surrounds an axis (I), and has inner and outer surfaces 61, 62. The outer surface 62 of the tubular hub body 6 is formed with an axially extending groove 60 that is defined by a groove-defining wall 63. The groove-defining wall 63 of the tubular hub body 6 has opposite first and second wall portions 631, 632, and an intermediate wall portion 633 that interconnects the first and second wall portions 631, 632 thereof. In this embodiment, the second wall portion 632 is higher than the first wall portion 631 with respect to the intermediate wall portion 633.

[0022]With further reference to FIG. 6, the securing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com