Padding finishing method for polyvinyl alcohol nonwoven fabric

A technology of polyvinyl alcohol and non-woven fabrics, applied in the processing of textile materials, liquid/gas/steam textile material processing, fiber processing, etc., can solve the problems of intensified decomposition, low processing efficiency, instability, etc. Increased elongation, improved mechanical properties, and enhanced overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

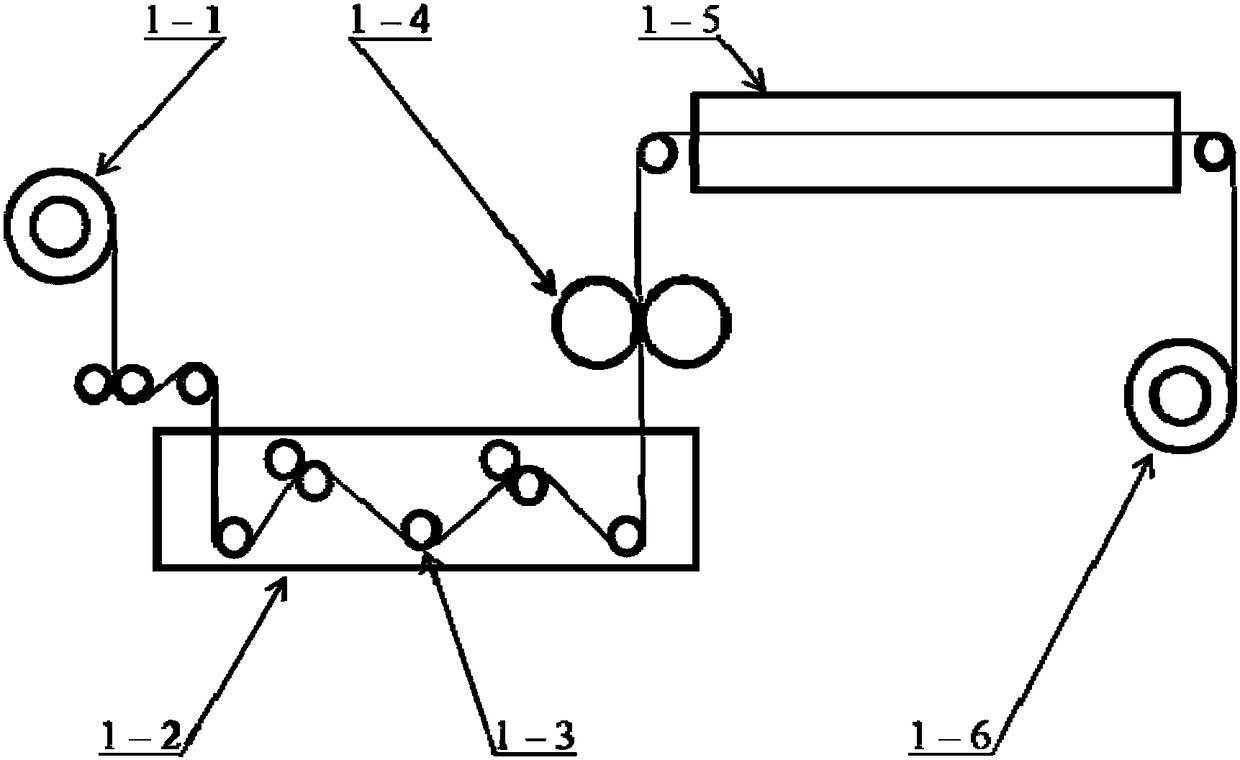

[0033] The padding finishing of polyvinyl alcohol nonwoven fabric specifically comprises the following steps:

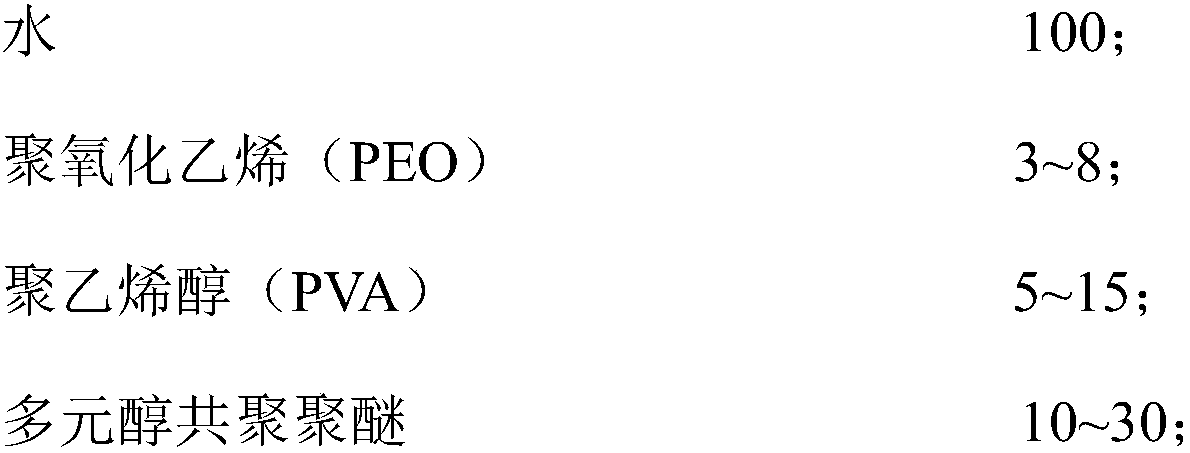

[0034] (1) Soaking solution for finishing, the soaking solution is calculated in parts by weight, and includes the following components:

[0035]

[0036]

[0037] The materials in the impregnating liquid are measured and heated in water to fully dissolve into a uniform aqueous solution to obtain the impregnating liquid;

[0038] (2) Specification of polyvinyl alcohol non-woven fabric for finishing: 60g / m 2 ;

[0039] (3) Padding finishing process: the polyvinyl alcohol non-woven fabric is released from the unwinding roller 1-1, enters the dipping tank 1-2 through the guide roll, and is fully impregnated in the dipping tank through the dipping guide roll 1-3, and then After being dried by the padding rolls 1-4, it enters the drying channel 1-5 for drying treatment; after drying treatment, it is wound by the finished winding rolls 1-6.

[0040] (4) Padding fi...

Embodiment 2

[0046] The padding finishing of polyvinyl alcohol nonwoven fabric specifically comprises the following steps:

[0047] (1) Soaking solution for finishing, the soaking solution is calculated in parts by weight, and includes the following components:

[0048]

[0049] The materials in the impregnating liquid are measured and heated in water to fully dissolve into a uniform aqueous solution to obtain the impregnating liquid;

[0050] (2) Specification of polyvinyl alcohol non-woven fabric for finishing: 15g / m 2 ;

[0051] (3) Padding finishing process: the polyvinyl alcohol non-woven fabric is released from the unwinding roller 1-1, enters the impregnation tank 1-2 through the guide roller, and is fully impregnated in the impregnation tank by the impregnation guide roller 1-3, and then after After the padding rolls 1-4 are dried, they enter the drying channel 1-5 for drying treatment; after the drying treatment, they are wound up by the finished winding rolls 1-6.

[0052](...

Embodiment 3

[0058] The padding finishing of polyvinyl alcohol nonwoven fabric specifically comprises the following steps:

[0059] (1) Soaking solution for finishing, the soaking solution is calculated in parts by weight, and includes the following components:

[0060]

[0061] The materials in the impregnating liquid are measured and heated in water to fully dissolve into a uniform aqueous solution to obtain the impregnating liquid;

[0062] (2) Specification of polyvinyl alcohol non-woven fabric for finishing: 20g / m 2 ;

[0063] (3) Padding finishing process: the polyvinyl alcohol non-woven fabric is released from the unwinding roller 1-1, enters the dipping tank 1-2 through the guide roll, and is fully impregnated in the dipping tank through the dipping guide roll 1-3, and then After being dried by the padding rolls 1-4, it enters the drying channel 1-5 for drying treatment; after drying treatment, it is wound by the finished winding rolls 1-6.

[0064] (4) Padding finishing proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com