Aluminium oxide full-automatic on-line spoil removing solid-liquid separation method

A solid-liquid separation, fully automatic technology, applied in alumina/aluminum hydroxide and other directions, can solve the problems of increasing the production cost of alumina products, low production efficiency, large equipment investment, etc., achieving obvious energy saving effect, small investment, The effect of low liquid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

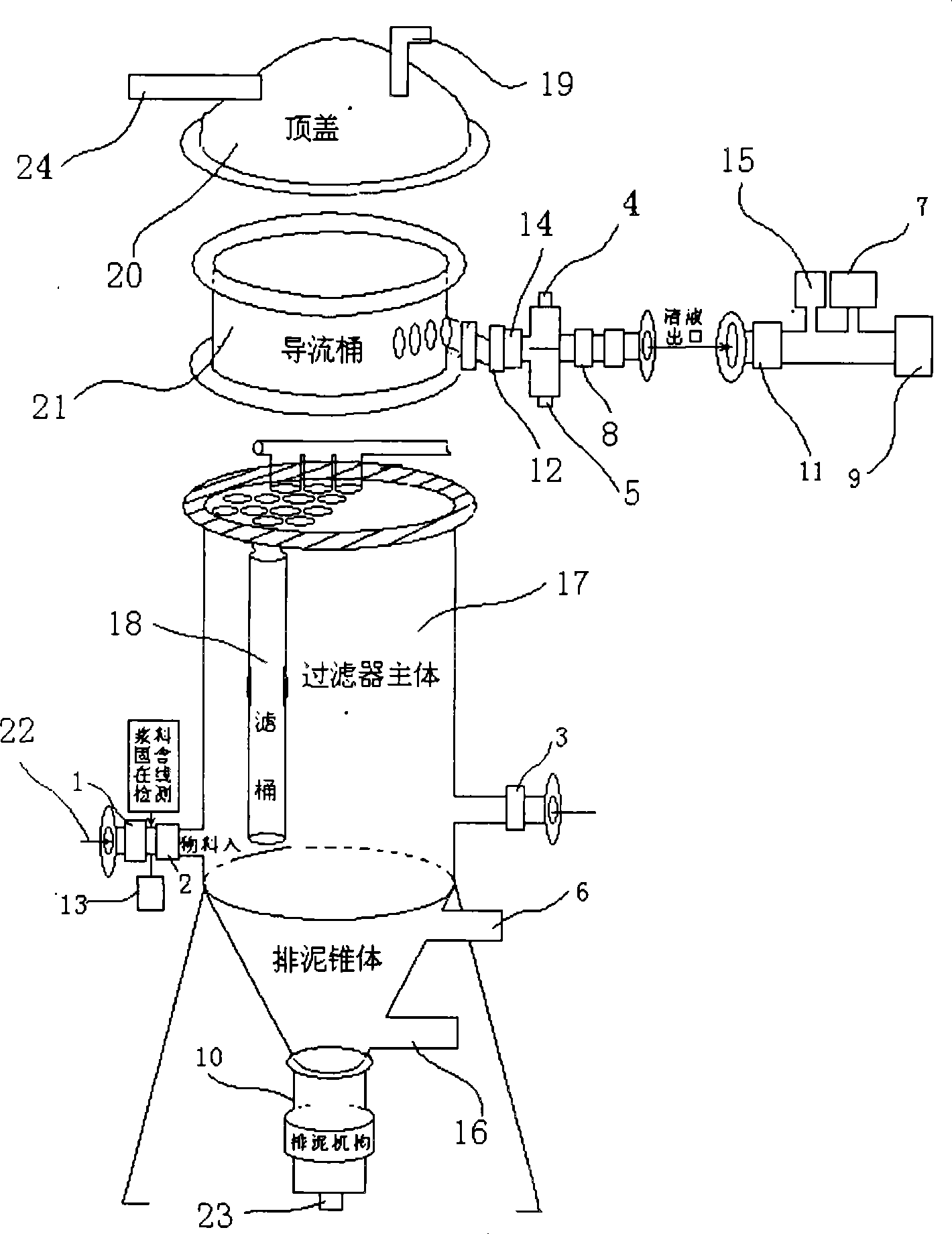

[0030] The specific embodiment of the present invention is as figure 1 As shown, the filter body at least includes a cylindrical semicircular top cover 20, a guide cylinder 21, a filter 17, and a cone mud discharge mechanism 10 connected with the columnar filter body. A draft tube 21 is connected between the top cover 20 and the filter 17 .

[0031] Filtration process:

[0032] Open the feed valve 13, the feed pump 1 (frequency tuned) will pass the diluted slurry through the filter inlet 22 at a rate of 4-10kg / cm 2 The pressure pumped into the cartridge filter 17 is filtered by the filter cartridge 18, and then the clear liquid outlet is output to the next process by the clear night pump 8 on the side of the guide cylinder 21. A float detector 12 is installed at the outlet of the clear liquid, and the float detector 12 detects whether the float content in the output semen after filtration meets the requirements of the subsequent production process. Generally, the float conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com