Solid and liquid separation device for sewage

A solid-liquid separation and sewage technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of poor sealing of the filter chamber, high labor intensity, and reduced efficiency of the filter press, and achieve the elimination of personnel assistance The effects of sex work, reducing labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

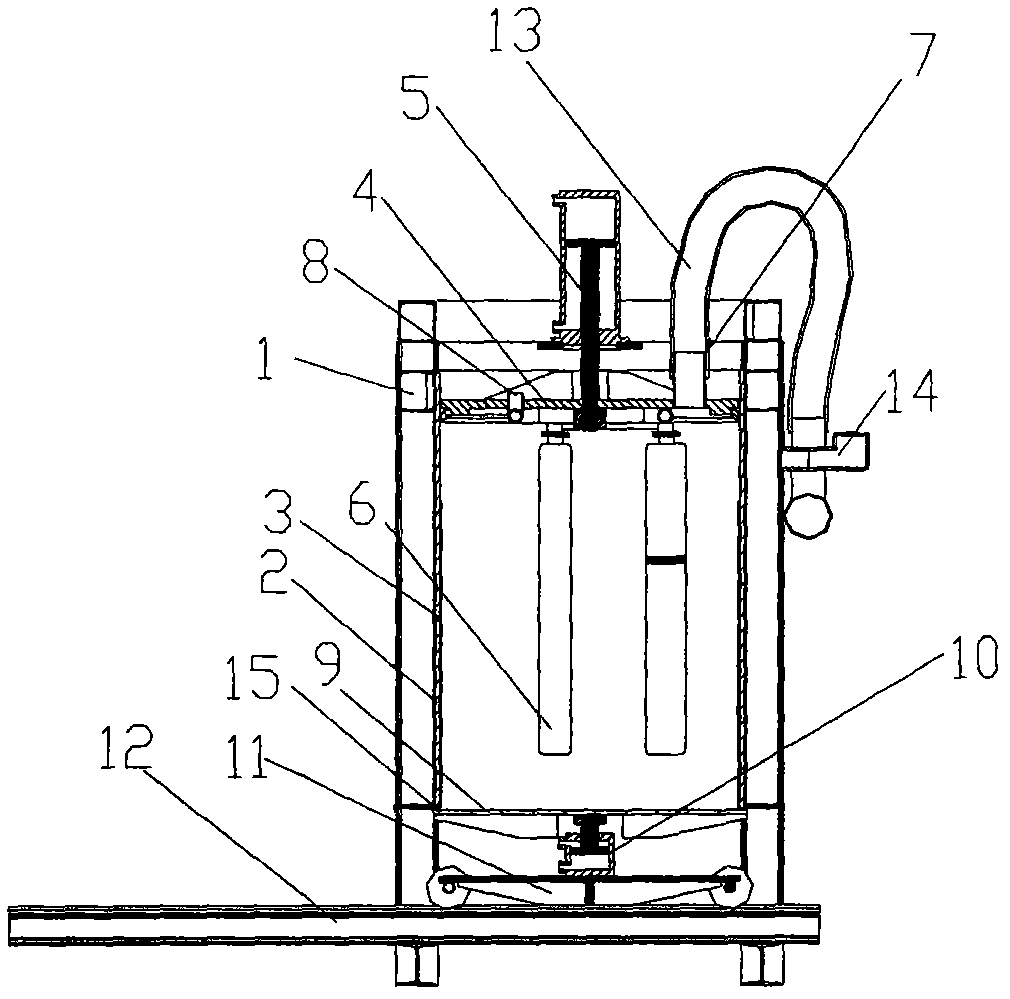

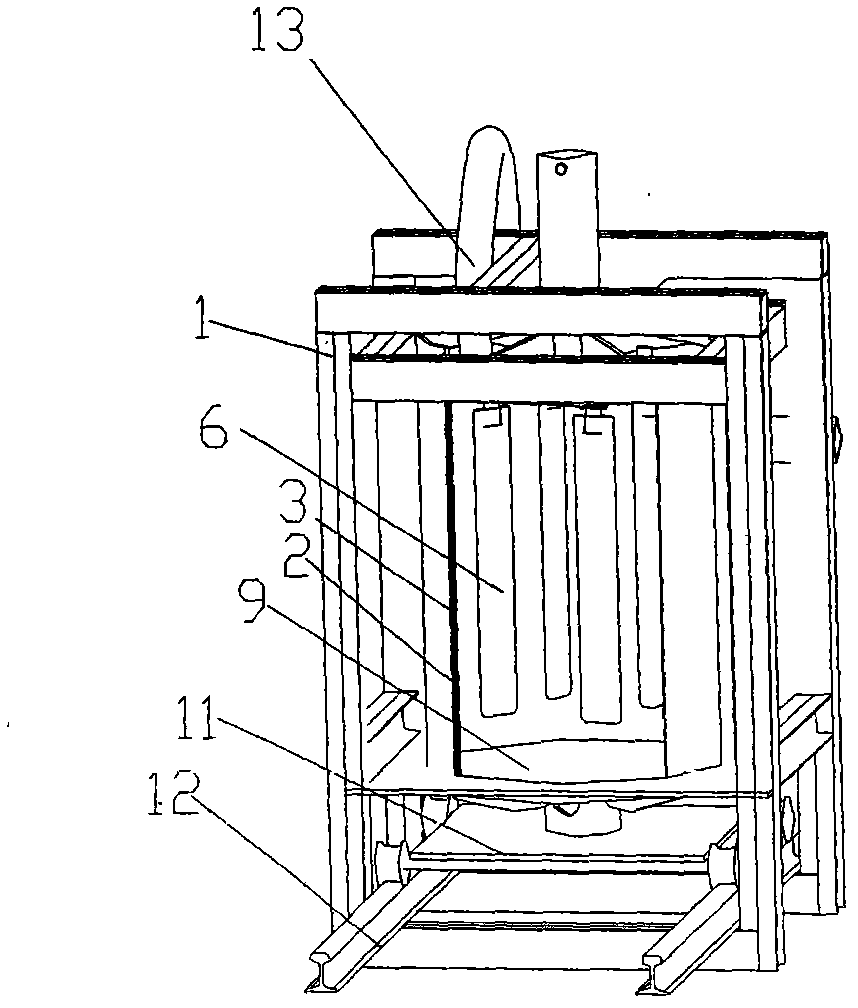

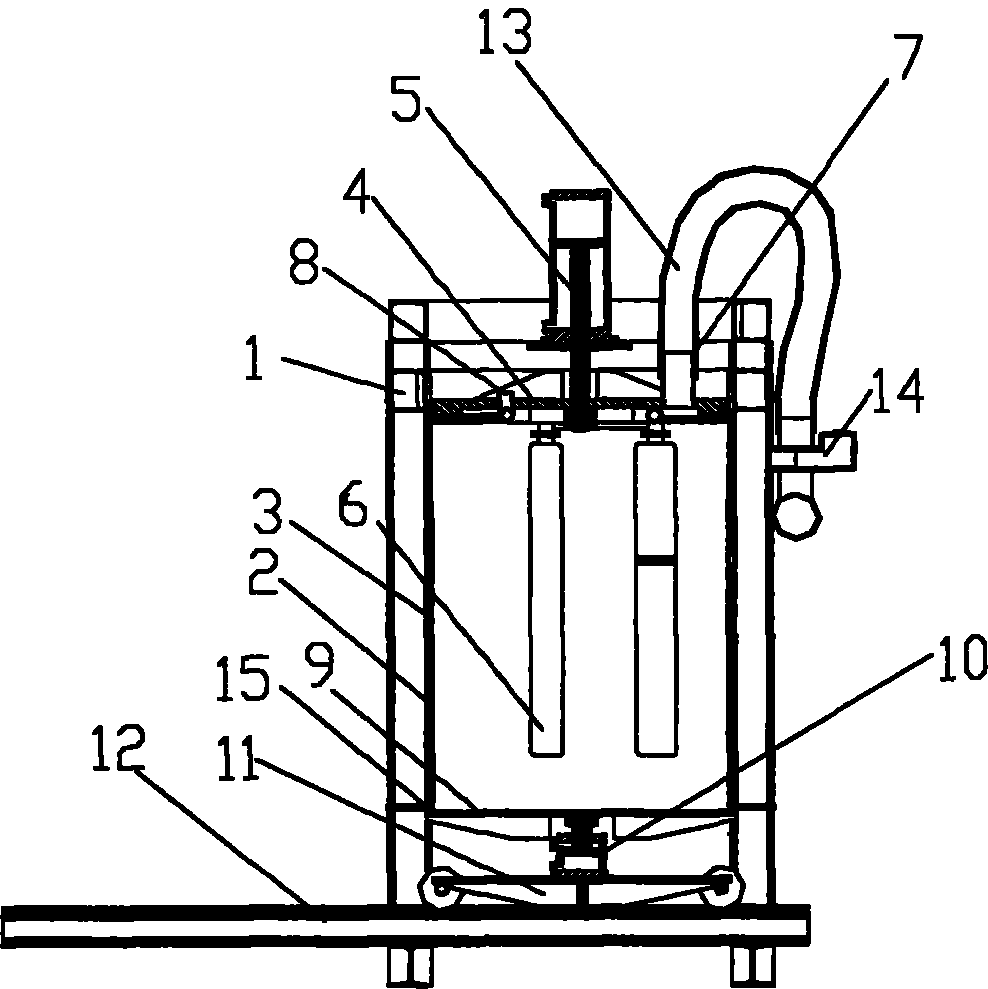

[0020] Further description will be made below in conjunction with the accompanying drawings, but not limited thereto.

[0021] It includes a frame 1 , a filter cartridge 2 supported by the frame 1 , a filter cartridge upper cover 4 , a filter cartridge lower cover 9 , and a filtrate feed port 7 connected to the filter barrel 2 .

[0022] An expansion device 6 is installed in the cylinder body 2 on the upper cover 4 , and the expansion device 6 is four expansion tubes and an expansion medium feed port 8 opened on the upper cover 4 .

[0023] The moving device of the lower cover 9 of the filter cartridge is that the lower cover 9 is connected with a control cylinder 10 that can move the lower cover 9 up and down. 11 moves out on the moving track 12 directly below filter cartridge 2.

[0024] The filter cartridge loam cake 4 is connected with the control oil cylinder 5 that can make loam cake 4 slide up and down on cylinder body 2 inwalls.

[0025] A number of liquid outlet hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com