Comprehensive utilization method of fluosilicic acid-containing wastewater

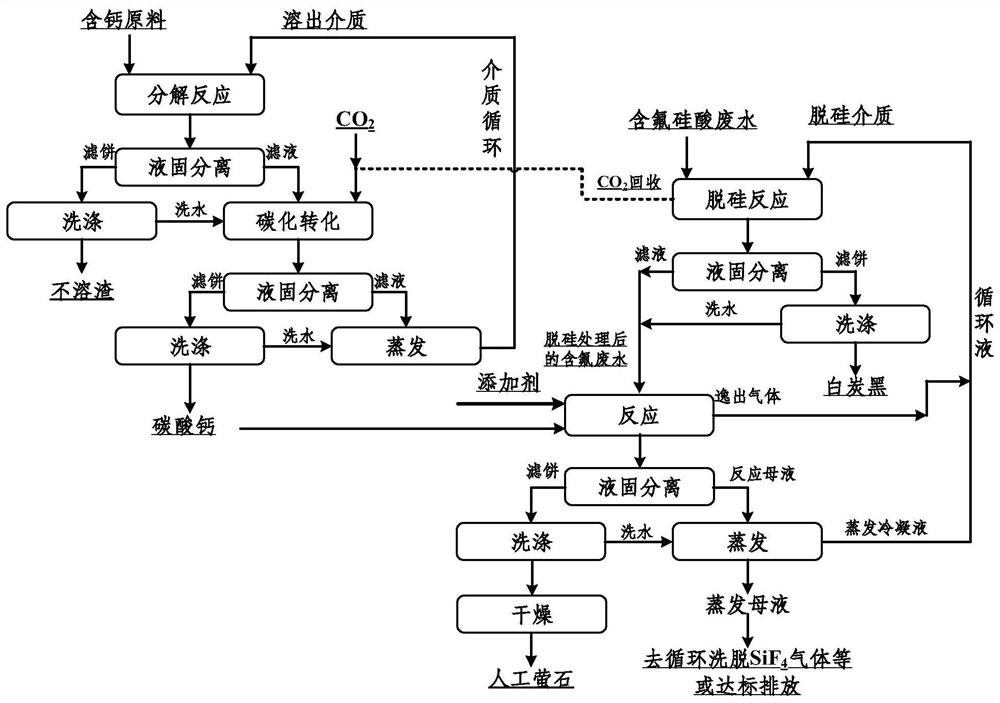

A technology for wastewater and silicic acid, applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., can solve the problem of less research on fluorosilicic acid wastewater treatment methods, and the inability to separate calcium fluoride solid, The problem of high cost of raw materials can achieve the effect of good liquid-solid separation performance, no equipment material and type, and low liquid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

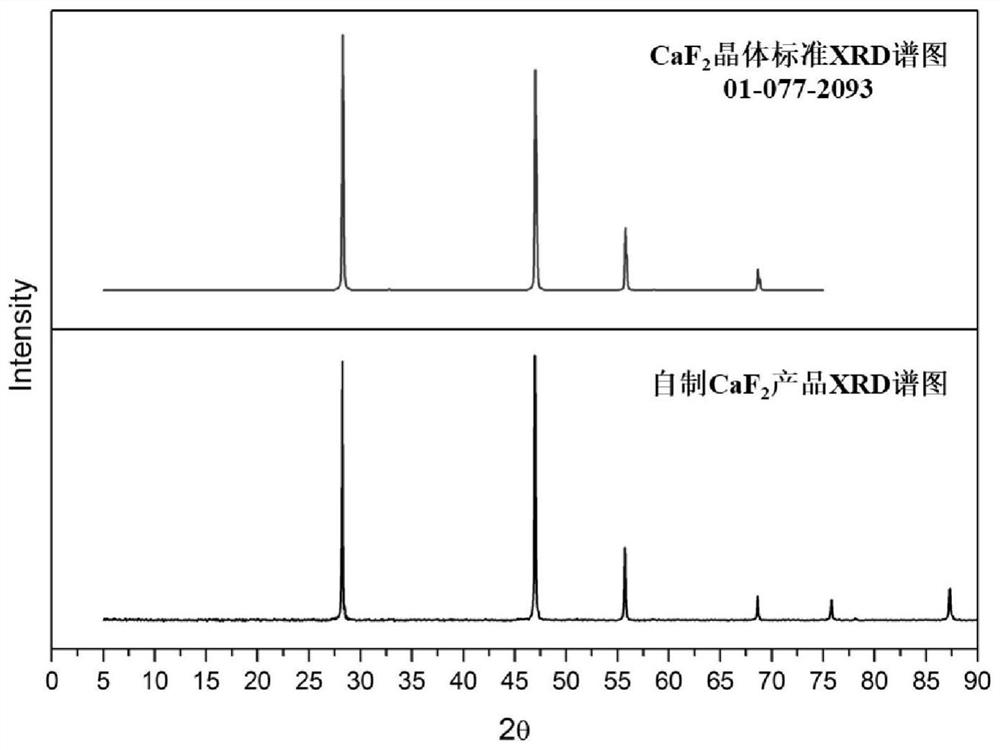

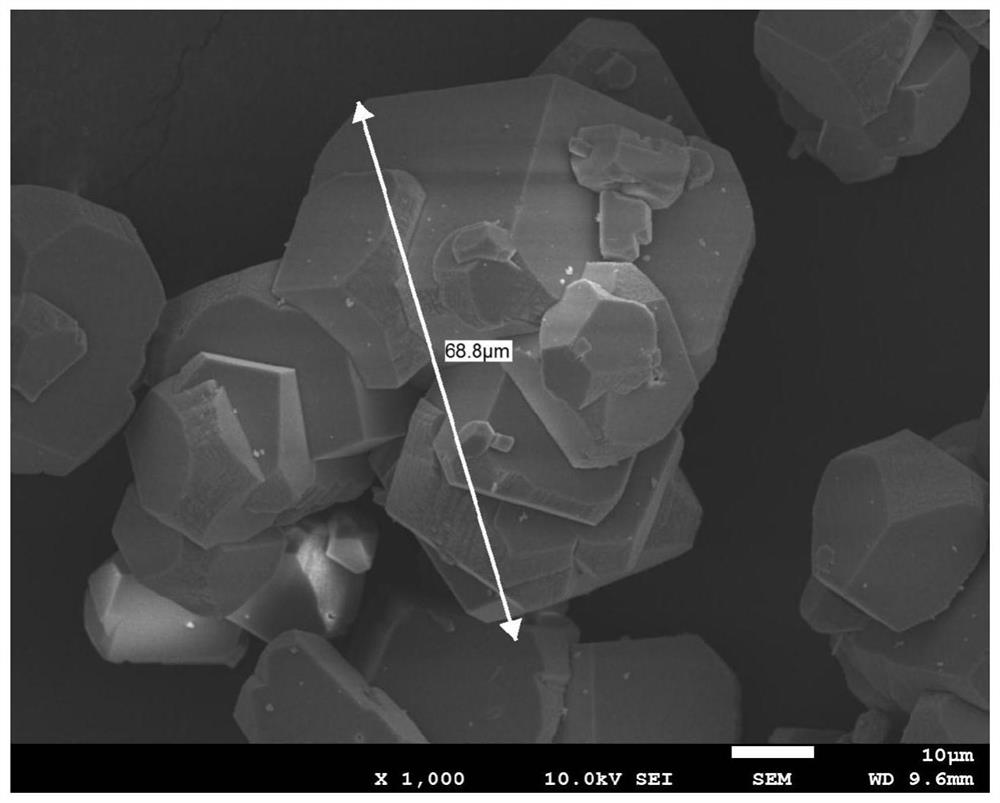

Examples

Embodiment 1

[0081] This embodiment provides a method for comprehensive utilization of fluorine-containing silicic acid wastewater. The fluorine-containing silicic acid wastewater is fluorine-containing silicic acid wastewater obtained from the fluidized bed waste gas condensate of an aluminum fluoride factory in Henan, wherein H 2 SiF 6 The mass concentration of HF is 32.64g / L, and the mass concentration of HF is 16.45g / L; Described comprehensive utilization method adopts industrial lime as calcium-containing raw material, and its chemical composition is as shown in table 1:

[0082] Table 1

[0083]

[0084] The comprehensive utilization method includes the steps of:

[0085] (1) Mix industrial lime with an aqueous solution of ammonium chloride, carry out a decomposition reaction at 50° C. for 2 hours, and obtain a calcium chloride-containing solution and insoluble slag through liquid-solid separation of the reacted calcium chloride-containing feed liquid;

[0086] Wherein, the rati...

Embodiment 2

[0093] This embodiment provides a method for comprehensive utilization of fluorine-containing silicic acid wastewater. The fluorine-containing silicic acid wastewater is fluorine-containing silicic acid wastewater produced by a fluorine chemical industry in Shandong, wherein H 2 SiF 6 The mass concentration of is 216.5g / L; Described comprehensive utilization method adopts industrial lime described in embodiment 1 as calcium-containing raw material, and its chemical composition is as shown in table 1;

[0094] The comprehensive utilization method includes the steps of:

[0095] (1) Mix industrial lime with an aqueous solution of ammonium nitrate, carry out a decomposition reaction at 100° C. for 0.05 h, and obtain a calcium nitrate-containing solution and insoluble slag through liquid-solid separation of the reacted calcium nitrate-containing feed liquid;

[0096] Wherein, the ratio of the ammonium nitrate to the amount of CaO in the industrial lime is 2.3:1; the washing water...

Embodiment 3

[0103] This embodiment provides a method for comprehensive utilization of fluorine-containing silicic acid wastewater. The fluorine-containing silicic acid wastewater is fluorine-containing silicic acid wastewater produced by a polysilicon refining enterprise in Jiangsu, wherein H 2 SiF 6 The mass concentration of HF is 12.55g / L, and the mass concentration of HF is 2.6g / L; Described comprehensive utilization method adopts industrial lime described in embodiment 1 as calcium-containing raw material, and its chemical composition is as shown in table 1;

[0104] The comprehensive utilization method includes the steps of:

[0105] (1) Mix industrial lime with an aqueous solution of ammonium chloride, carry out a decomposition reaction at 20° C. for 3 hours, and obtain a calcium chloride-containing solution and insoluble slag through liquid-solid separation of the reacted calcium chloride-containing feed liquid;

[0106] Wherein, the ratio of the ammonium chloride to the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com