Differential pressure type compressor gas lift wellhead pressure reduction device and pressure reduction method applying same

A technology of decompression device and compressor, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of compressor overload shutdown, rapid pressure change, affecting the efficiency of discharge and lifting, etc. The effect of preventing overpressure and efficient drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

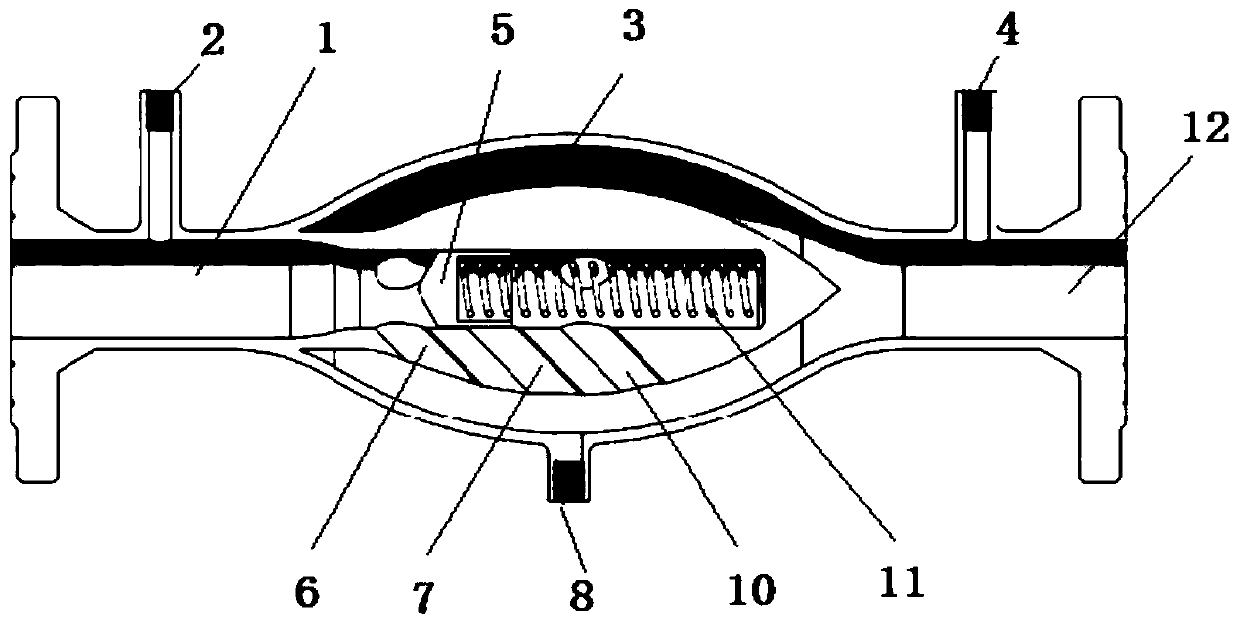

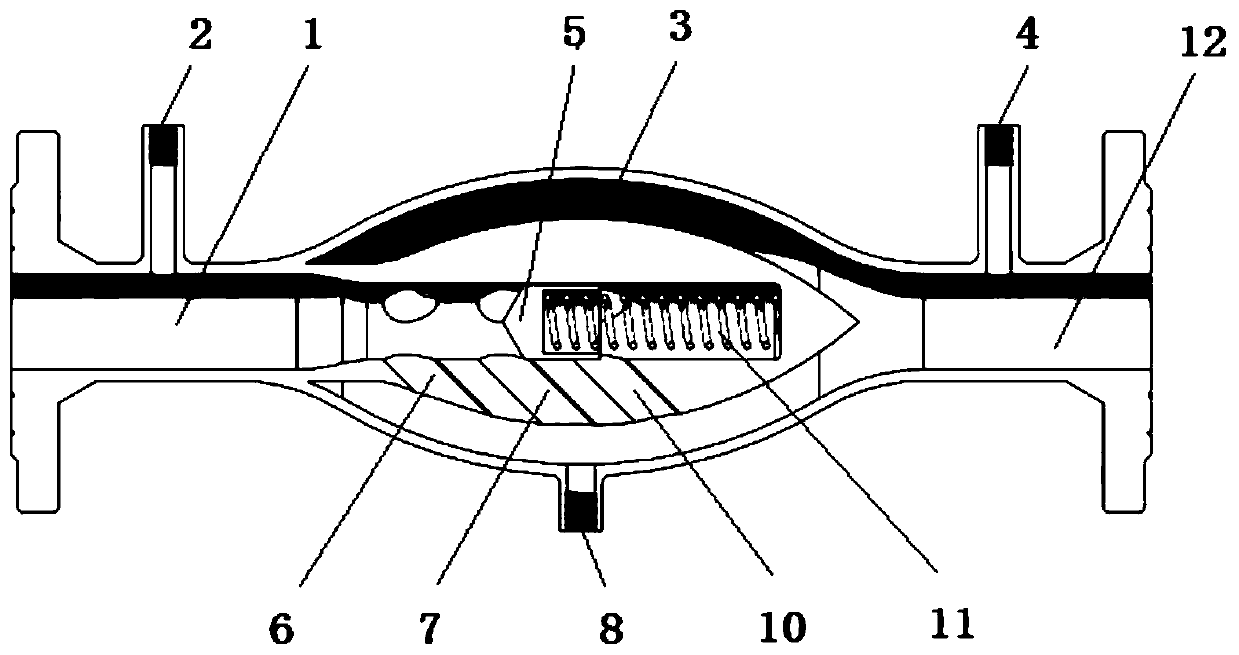

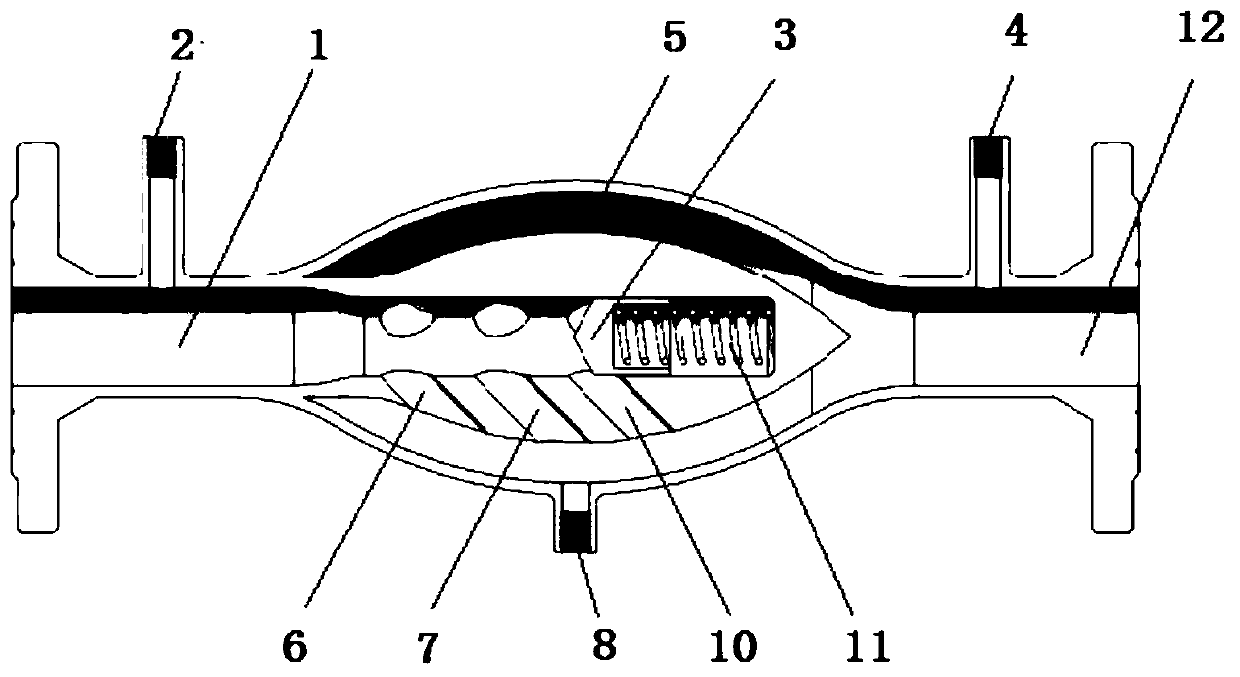

[0044] Attached below Figure 1-4 , the specific implementation of the present invention will be described in detail, but it should be understood that the protection scope of the present invention is not limited by the specific implementation. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0045] The present invention provides a differential pressure compressor gas lift wellhead decompression device, comprising:

[0046] Intake pipe;

[0047] Outlet pipe;

[0048] The decompression separation chamber includes a gas-liquid separation channel and a decompression channel, the decompression channel communicates with the inlet pipe, and the gas-liquid separation channel communicates with the outlet pipe;

[0049] At least two groups of diversion units, each group of diversion units is used to connect the decompressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com