Solid-liquid separation device

A technology for solid-liquid separation and driving device, which can be used in manufacturing tools, presses, etc., and can solve the problems of larger solid volume, increased transportation and processing costs, and time-consuming and labor-intensive problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained in conjunction with the accompanying drawings and examples.

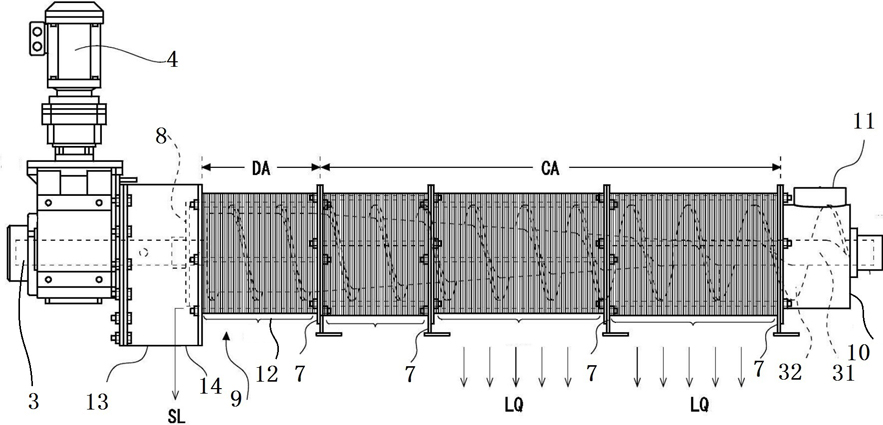

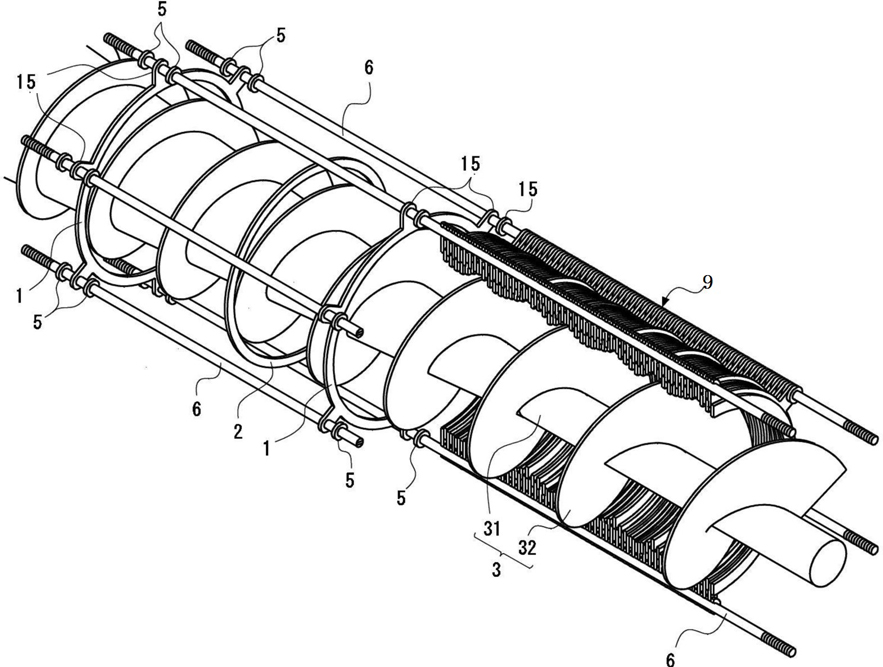

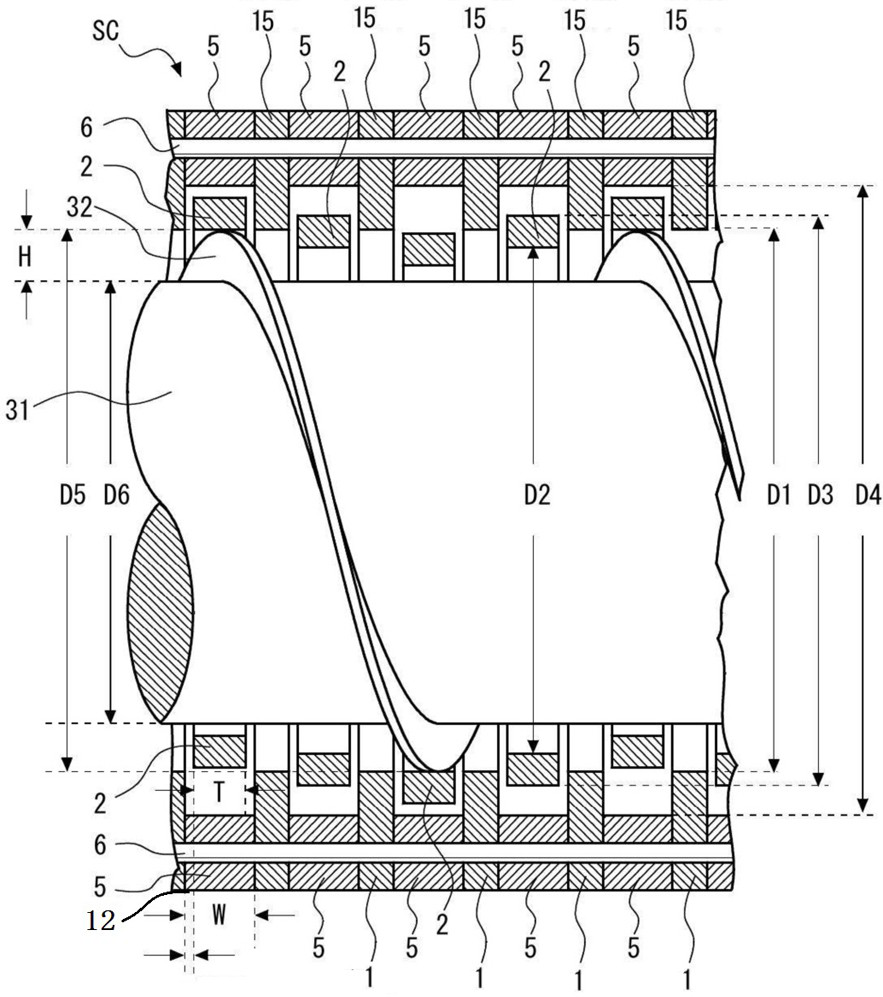

[0022] like figure 1 As shown, the solid-liquid separation device includes a filter cartridge 9, a drive device 4 provided in the filter cartridge 9 and a drive device 4 that rotates the helical conveyor 3, which is a feed in the introduction of the filter cartridge 9. The apparatus for separating solid SL and liquid LQ is first introduced from the conductive groove 10 provided with the feed port 11, followed by the rotation of the screw conveyor 3, the material is compressed and the fixed discharge port 14 is provided. The fixed discharge slot 13 is moved, at which time the liquid LQ in which the liquid LQ in the compressed material is discharged from the liquid discharge port 12 formed at the outer wall of the filter cartridge 9, the solid SL and liquid Lq in the material are separated; double head bolt 6 The end is fixed to the support plate 7, and the double hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com