Carbonate-removing method in alumina production

A carbonate and alumina technology, applied in chemical instruments and methods, aluminate/alumina/aluminum hydroxide purification, inorganic chemistry, etc., can solve the problem of high liquid content of carbonate filter cake, sedimentation and filtration Poor performance, difficult process operation and other problems, to improve the effect of salt discharge and reduce the effect of liquid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

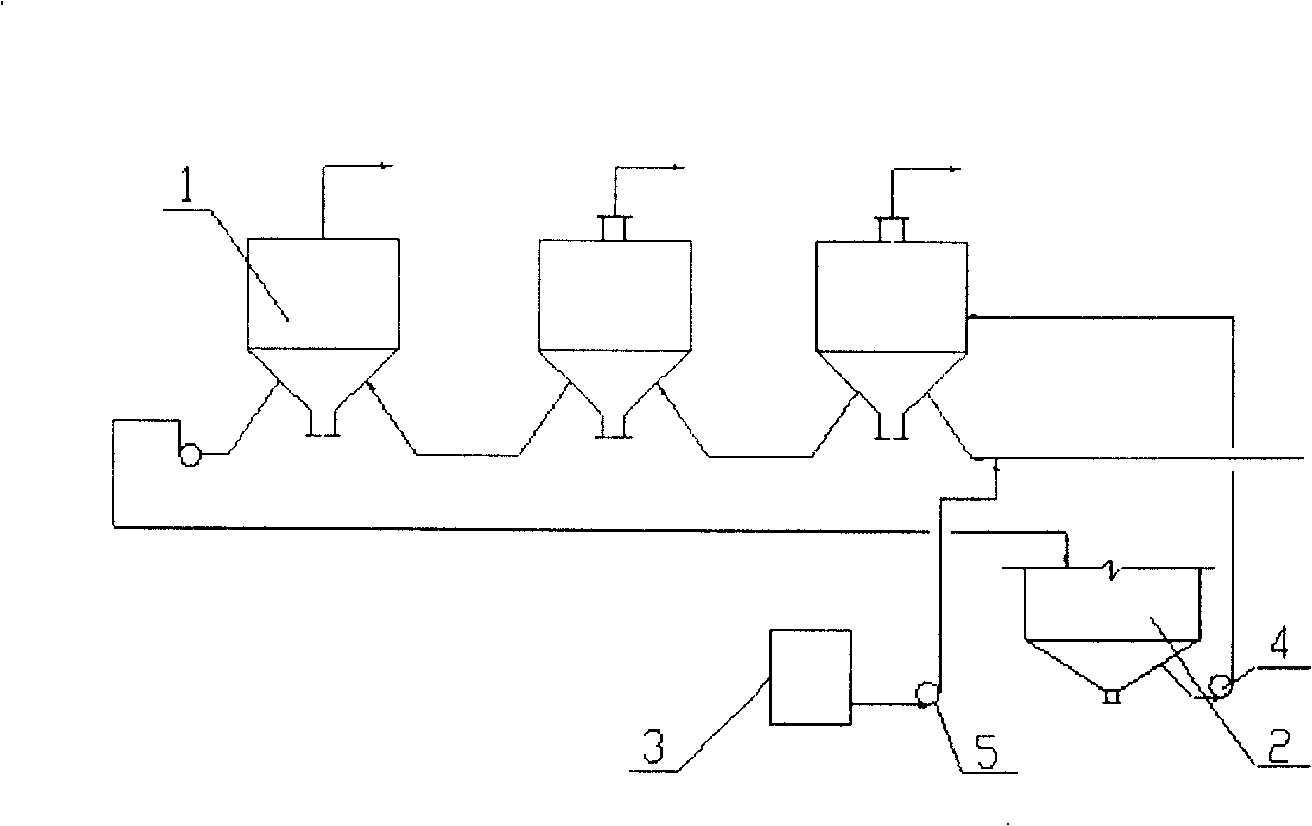

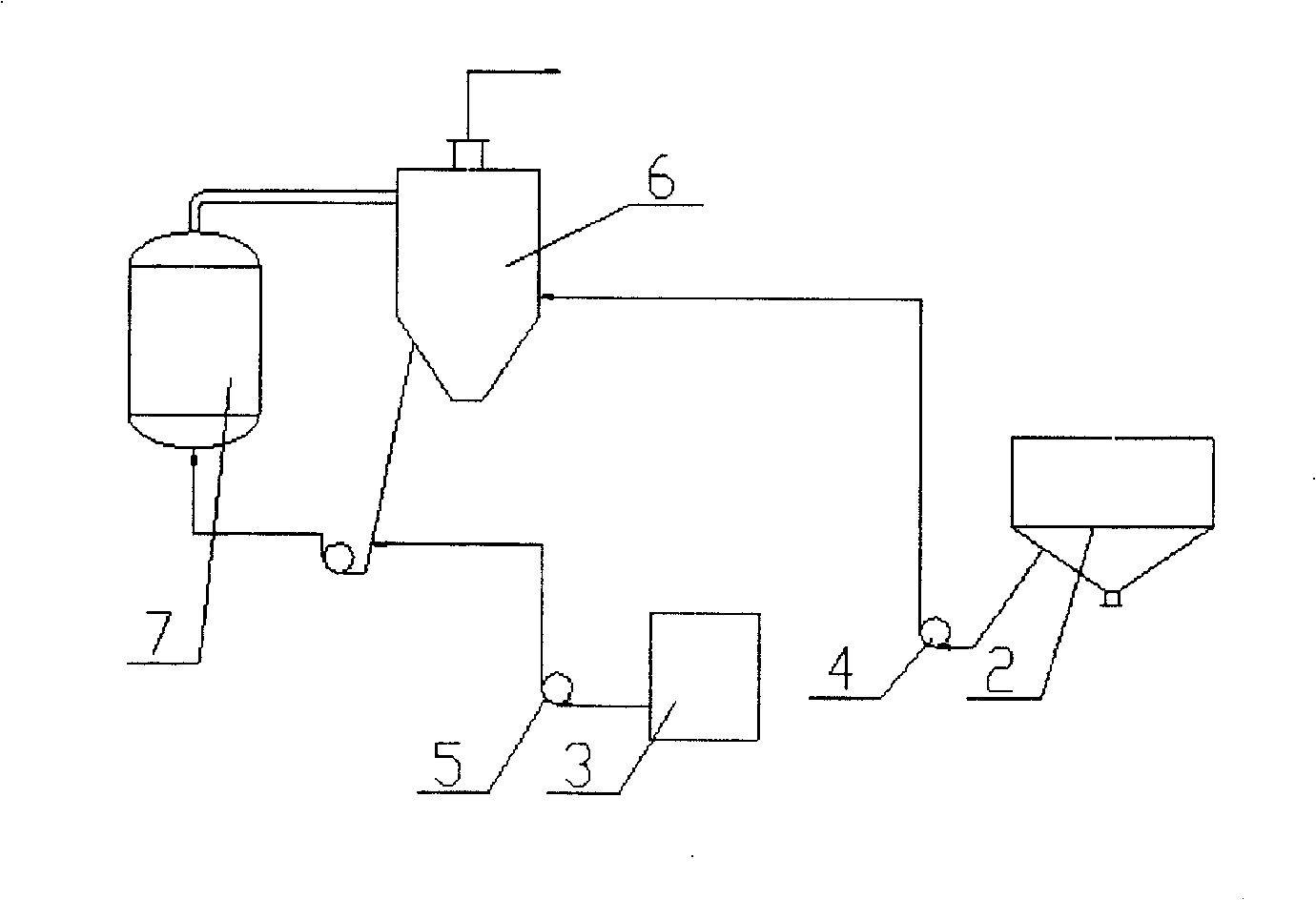

[0011] Embodiment of the present invention: set up a salt seed pump (4) on one side of the existing salt settling tank (2) in production and set up a lye pump (5) on one side of the high-concentration caustic alkali tank (3) ), using the above two pumps to send crystal seeds and high-concentration caustic alkali into the flash tank (1), or into the crystallization chamber (6) or the heating chamber (7) of the forced circulation evaporator through pipelines, to make the crystallization Most of the salt is anhydrous sodium carbonate with good sedimentation and filtration performance; in the process of forced circulation and flash evaporation, the caustic Na in the solution 2 o k When the concentration does not meet the requirement of salt discharge, add an appropriate amount of high-concentration caustic to make the caustic (Na 2 o k ) concentration reaches more than 320g / l, so that the salt equilibrium concentration in the solution after the salt discharge is reduced to below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com