High dehydration type rotation pressurization dehydrator

A dehydrator and rotating shaft technology, applied in the direction of presses, filtration separation, separation methods, etc., can solve the problems of insufficient dehydration and inability to form a uniform liquid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

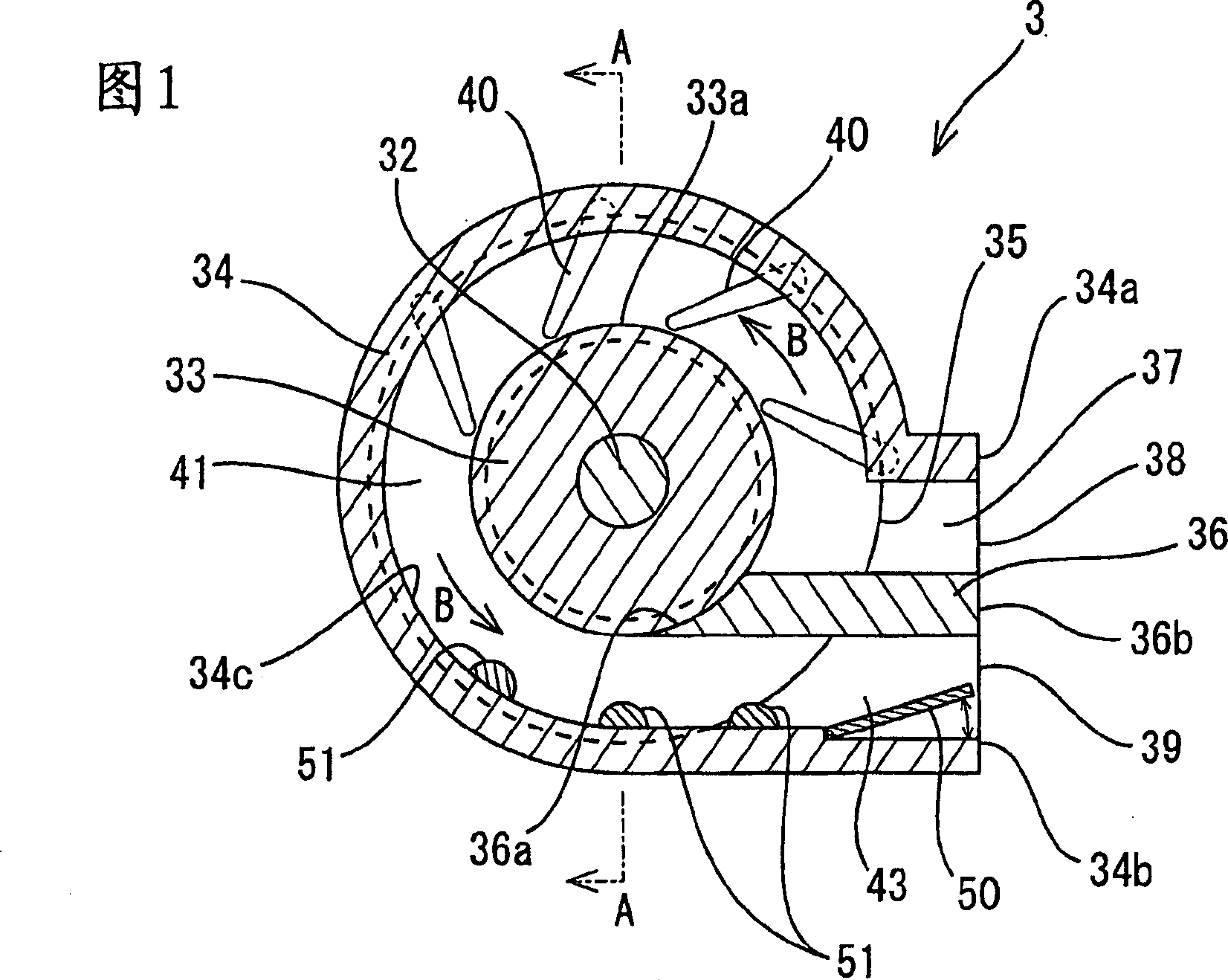

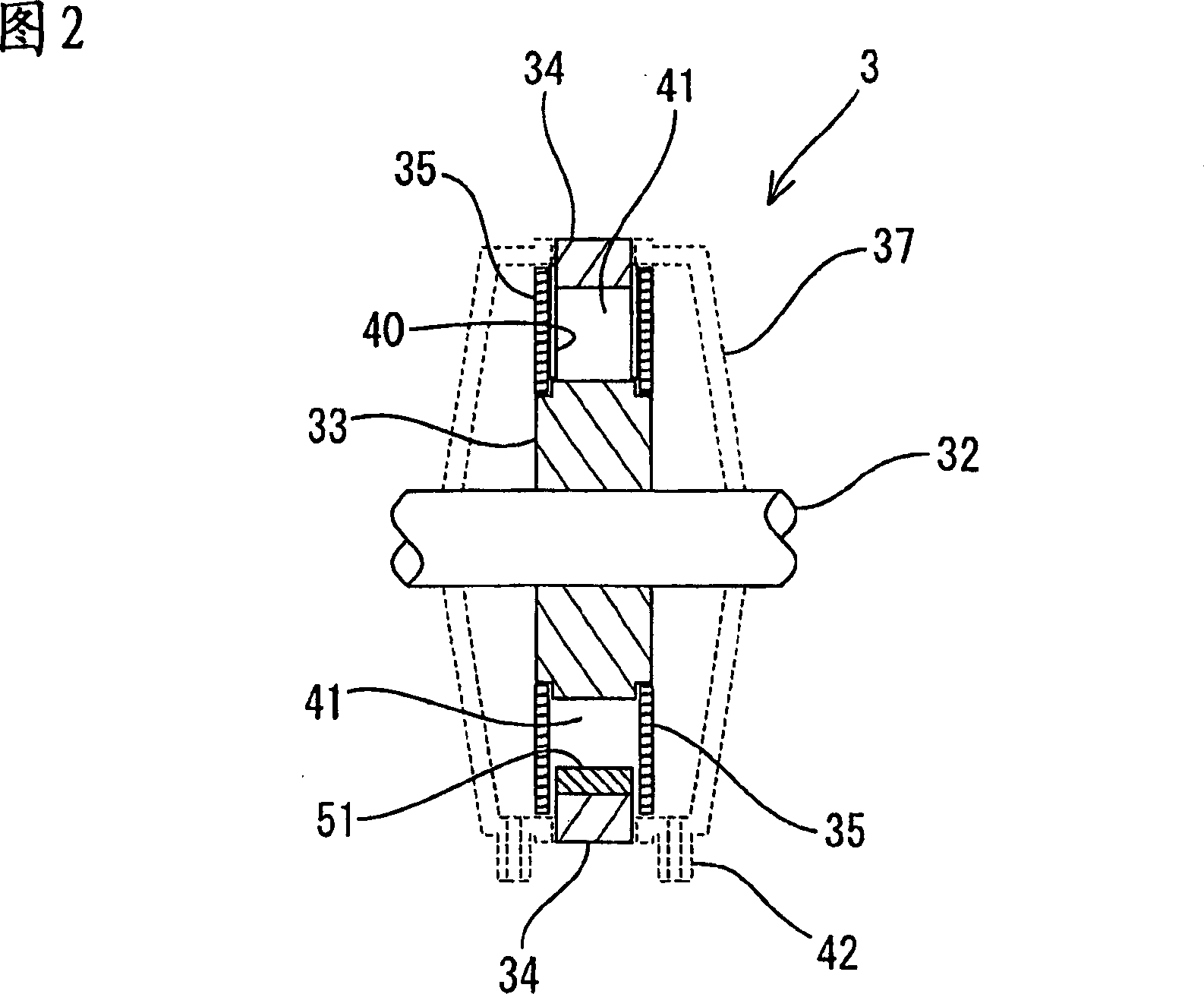

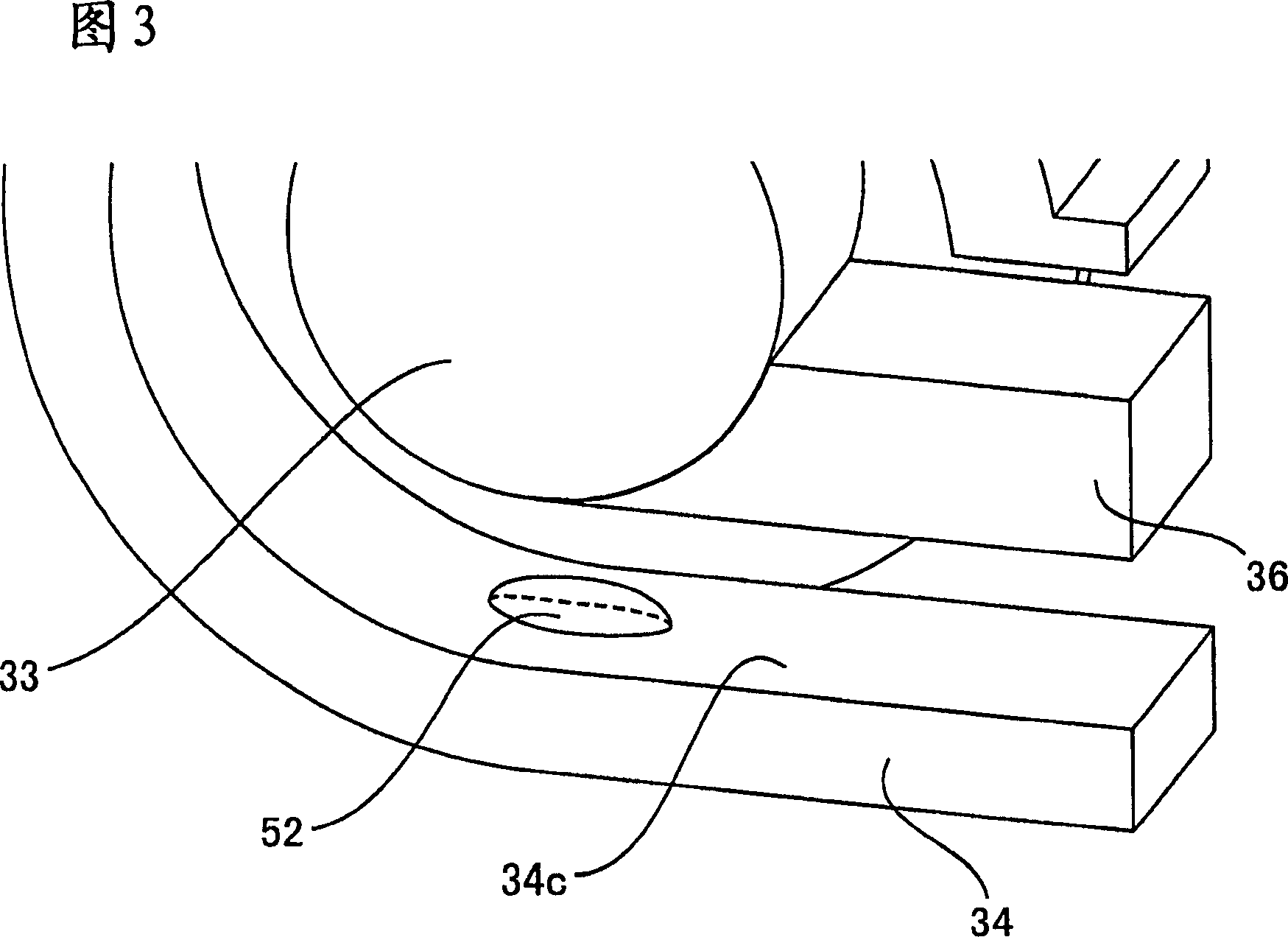

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Fig. 1 is a cross-sectional view showing the basic structure of a high dehydration type rotary pressurized dehydrator 3 according to the present invention. FIG. 2 is a sectional view taken along line AA of the rotary pressurized dehydrator 3 shown in FIG. 1 . As shown in the figure, the rotary pressure dehydrator 3 consists of a rotating shaft 32, an inner ring bushing 33, an outer ring bushing 34, two annular sieves 35, a scraper 40, a guide 36, a raw material supply port 38, Filter cake outlet 39, back pressure plate 50, outer casing 37 etc. constitute.

[0029] In this rotary pressurization dehydrator 3 , when a driving force is supplied from a driving device not shown to rotate the rotating shaft 32 , the inner ring bushing 33 fixed around the rotating shaft 32 and the inner ring bushing 33 fixed The two sieves 35 on the top rotate together with the rotating shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com