Fabric with good antibacterial property for curtains

A high-performance, good technology, applied in the field of curtain fabrics, can solve the problems of reduced fabric practicability, single fiber effect, beautiful fabrics without other functions, etc., to achieve good high temperature resistance, good radiation resistance, and good antistatic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

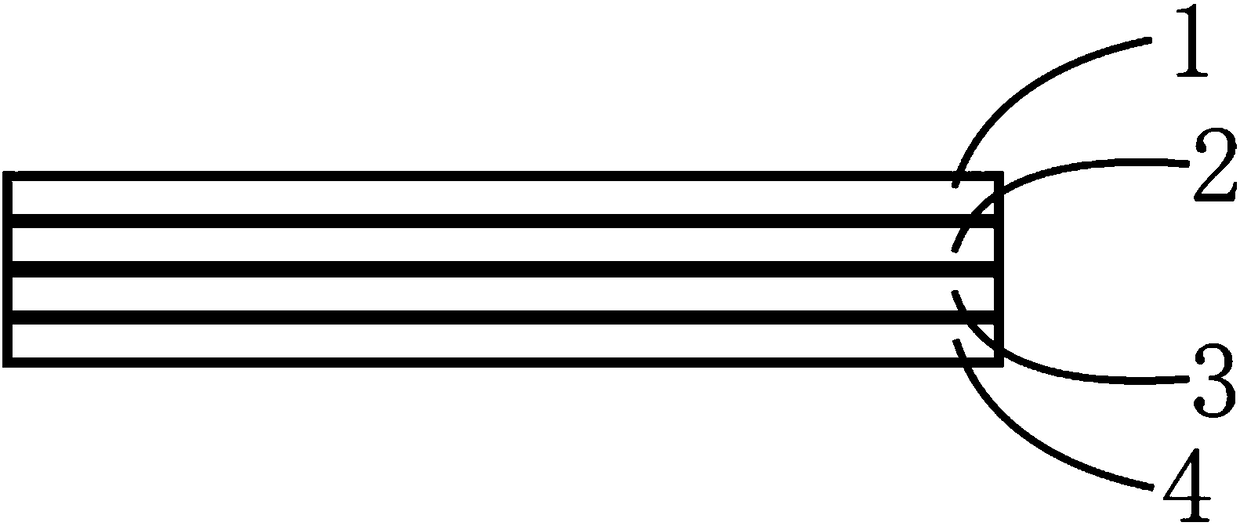

Image

Examples

preparation example Construction

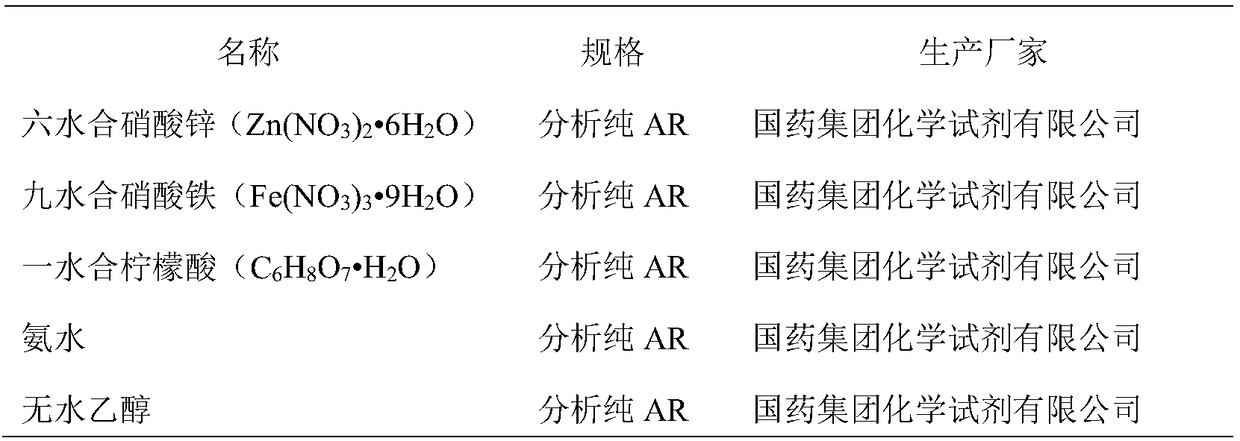

[0029] The preparation process of the above-mentioned antibacterial agent I is as follows: Weigh 0.1M zinc nitrate and 0.03M ferric nitrate respectively, dissolve them in 200ml distilled water, and then magnetically stir until transparent; then add citric acid, magnetically stir until fully dissolved, wherein, making The molar ratio of zinc nitrate and citric acid is 1:1.5; add ammonia water (30wt.%) dropwise with a constant pressure titration funnel, adjust pH = 8, evaporate water in a constant temperature water bath at 86°C to form a wet gel, and then vacuum dry at 80°C Dry in an oven for 24 hours until constant weight to obtain Fe-ZnO xerogel; calcinate the xerogel in air at 540°C for 1 hour, and cool naturally to room temperature to obtain antibacterial agent I, namely nano-Fe-ZnO antibacterial agent.

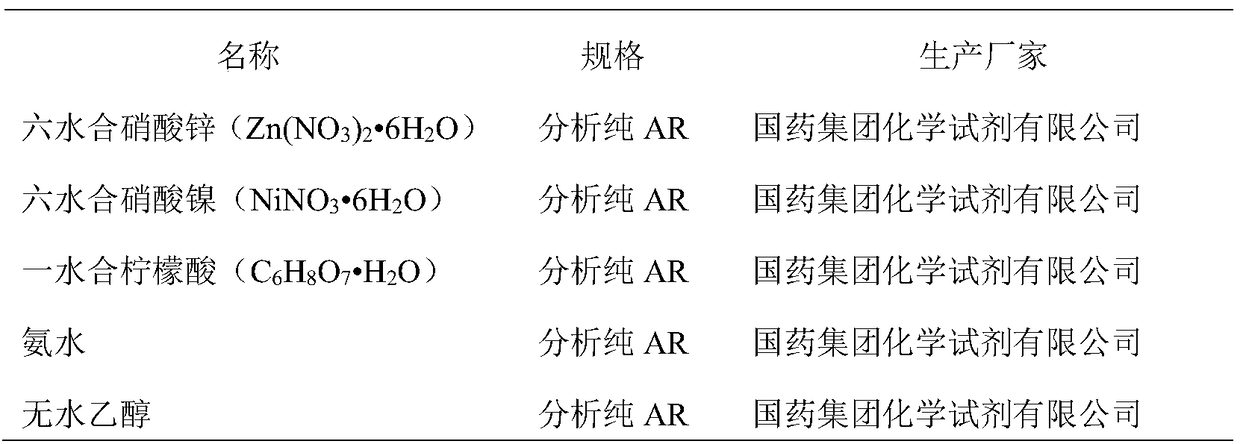

[0030] Wherein, the antibacterial agent II is a nano-Ni-ZnO antibacterial agent prepared by a gel-sol method, and the nano-Ni-ZnO antibacterial agent is shown as nanoparticl...

Embodiment 1

[0037] In this example, an antibacterial polyester fiber, first prepare antibacterial agent I and antibacterial agent II, mix them to form an antibacterial agent mixture, then use pure PET chips to blend with the antibacterial agent mixture to prepare antibacterial modified PET chips, and then melt The antibacterial polyester fiber is obtained by spinning.

[0038] The above-mentioned antibacterial polyester fiber includes: 0.5wt.% of antibacterial agent I, 0.9wt.% of antibacterial agent II, and the balance of polyester fiber according to weight percentage.

[0039] Among them, the antibacterial agent I is a nano-Fe-ZnO antibacterial agent prepared by gel-sol method; the nano-Fe-ZnO antibacterial agent is in the form of nanoparticles with a particle size of 600nm, and the molar ratio of Fe to ZnO is 3:10.

[0040] The antibacterial agent II is a nano-Ni-ZnO antibacterial agent prepared by a gel-sol method. The nano-Ni-ZnO antibacterial agent is in the form of nanoparticles wit...

Embodiment 2

[0042] In this example, an antibacterial polyester fiber, first prepare antibacterial agent I and antibacterial agent II, mix them to form an antibacterial agent mixture, then use pure PET chips to blend with the antibacterial agent mixture to prepare antibacterial modified PET chips, and then melt The antibacterial polyester fiber is obtained by spinning.

[0043] The above-mentioned antibacterial polyester fiber includes: 0.6 wt.% of antibacterial agent I, 1.0 wt.% of antibacterial agent II, and the balance of polyester fiber according to weight percentage.

[0044] Among them, the antibacterial agent I is a nano-Fe-ZnO antibacterial agent prepared by gel-sol method; the nano-Fe-ZnO antibacterial agent is in the form of nanoparticles with a particle size of 600nm, and the molar ratio of Fe to ZnO is 3:10.

[0045] The antibacterial agent II is a nano-Ni-ZnO antibacterial agent prepared by a gel-sol method. The nano-Ni-ZnO antibacterial agent is in the form of nanoparticles w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com