Nanofiltration membrane for extracting lithium from salt lake and preparation method of nanofiltration membrane

A technology of nanofiltration membrane and bottom membrane, which is applied in the field of nanofiltration membrane, can solve the problems of insufficient lithium ion separation effect and low lithium ion rejection rate, and achieve the goal of improving mechanical strength, improving hydrophilicity and improving dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

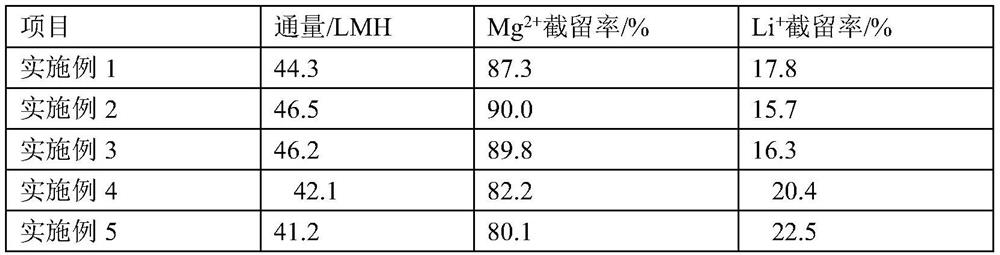

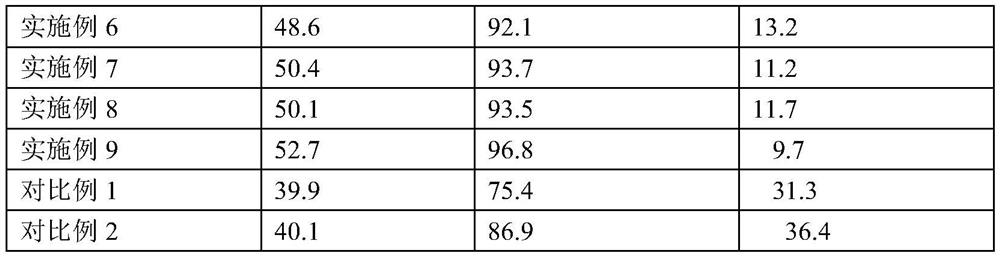

Examples

preparation example 1

[0042] A modified polyphenylsulfone prepared by the following method:

[0043] Put 10kg polyphenylsulfone into 100L chloroform solution, stir for 40min, then add 6kg chlorosulfonic acid, stir for 1.5h, stir for 15min, filter, wash the membrane with water 4 times, dry the solid at 65°C for 40min, A modified polyphenylsulfone was obtained.

Embodiment 1

[0046] A nanofiltration membrane for extracting lithium from a salt lake comprises a bottom membrane and a polyamide layer formed on the bottom membrane.

[0047] A preparation method of a nanofiltration membrane for extracting lithium from a salt lake, comprising the steps of:

[0048] S1: Preparation of aqueous phase solution: add 10 kg of piperazine to 90 kg of water, stir for 30 min, then add 2 kg of nano-zinc oxide, and stir for 15 min to obtain an aqueous phase solution;

[0049] S2: Preparation of oil phase solution: mix 7 kg of trimesoyl chloride and 85 kg of toluene, and stir for 40 min to obtain an oil phase solution;

[0050] S3: Interfacial polymerization: take a smooth glass plate of 50cm*50cm*5cm, wash it with water, and dry it at 25°C for 3 hours, and put it in the In 30kg N,N-dimethylacetamide, stir for 45min, then pour it on a glass plate, scrape the surface, immediately put the glass plate in 10kg N-methylpyrrolidone at 10°C, and the modified polyphenylsulfo...

Embodiment 2

[0053] A method for preparing a nanofiltration membrane for extracting lithium from a salt lake, which differs from Example 1 in that the amount of nano-zinc oxide added in step S1 is 4 kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com