Modified polysulfone composite material as well as preparation method and application thereof

A composite material and polysulfone technology, applied in the field of modified polysulfone composite material and its preparation, can solve the problems of stress cracking, complex structure, low impact strength, etc., and achieve the effect of eliminating stress cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

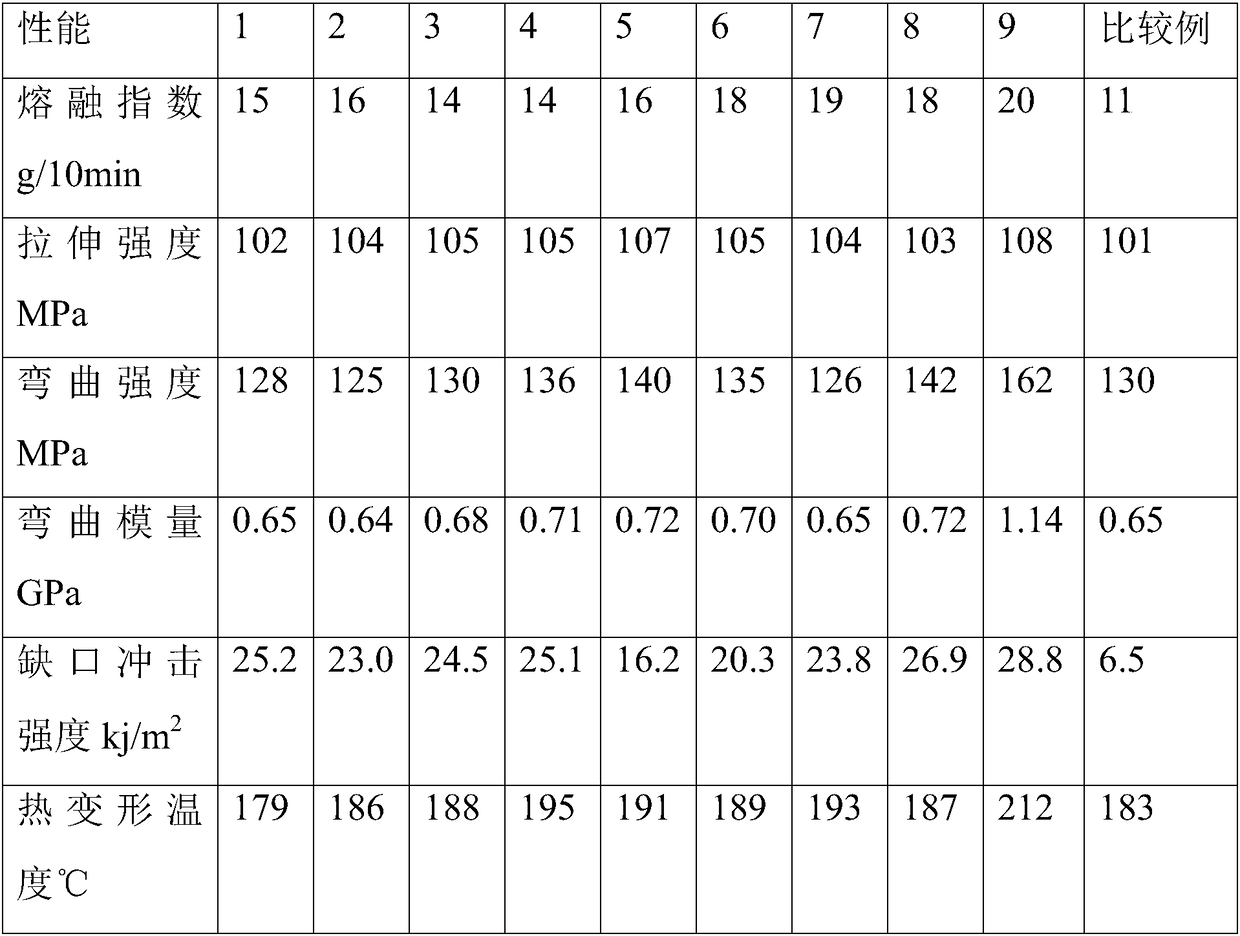

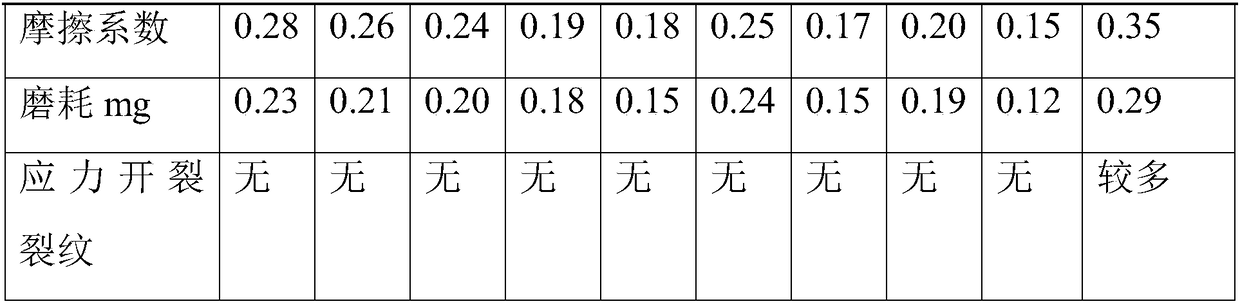

Examples

Embodiment 1

[0046] The preparation method of modified polysulfone composite material is example with embodiment 1:

[0047] formula:

[0048] PSU: 10kg, PPSU: 1.0kg, PBT: 0.5kg, GF: 2.0kg, antioxidant Hostanoxp-EP: 40g, silicone: 60g, molybdenum disulfide: 0.5kg.

[0049] Preparation process:

[0050] ① After mixing PSU and PPSU, dry at 140°C for 4 hours, and dry PBT at 120°C for 4 hours.

[0051] ② Stir the antioxidant, polysilicone and molybdenum disulfide at 200rpm, mix for 5 minutes, and then add to the metering tank B.

[0052] ③Mix the dried PSU, PPSU, and PBT resins at 200rpm for 5 minutes, add them to the metering tank A, and add the glass fiber to the metering tank C.

[0053] ④ Turn on the twin-screw extruder, measure A, B, and C in proportion to the weighing feeder, and continuously feed the materials into the twin-screw extruder, heat and melt, mix and extrude, cool, and pelletize to obtain the modified PSU composite material .

[0054] ⑤ Blending extrusion process: extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com