Dialysis membrane and method for its production

A technology of dialysis membrane and flat membrane, applied in dialysis system, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of reducing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

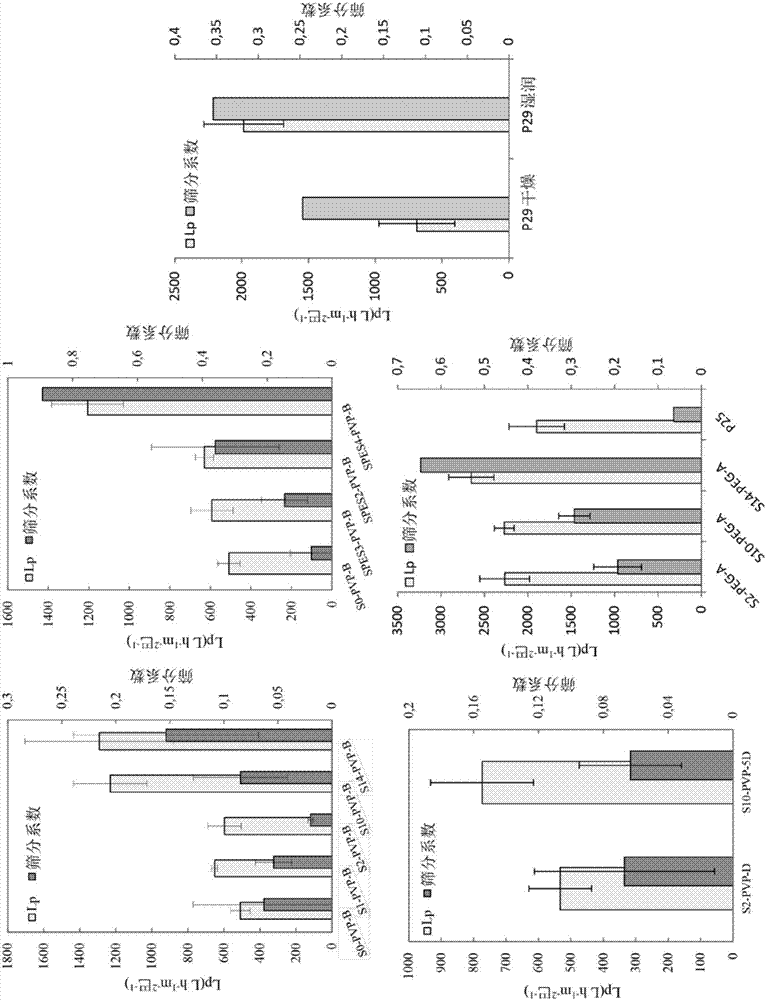

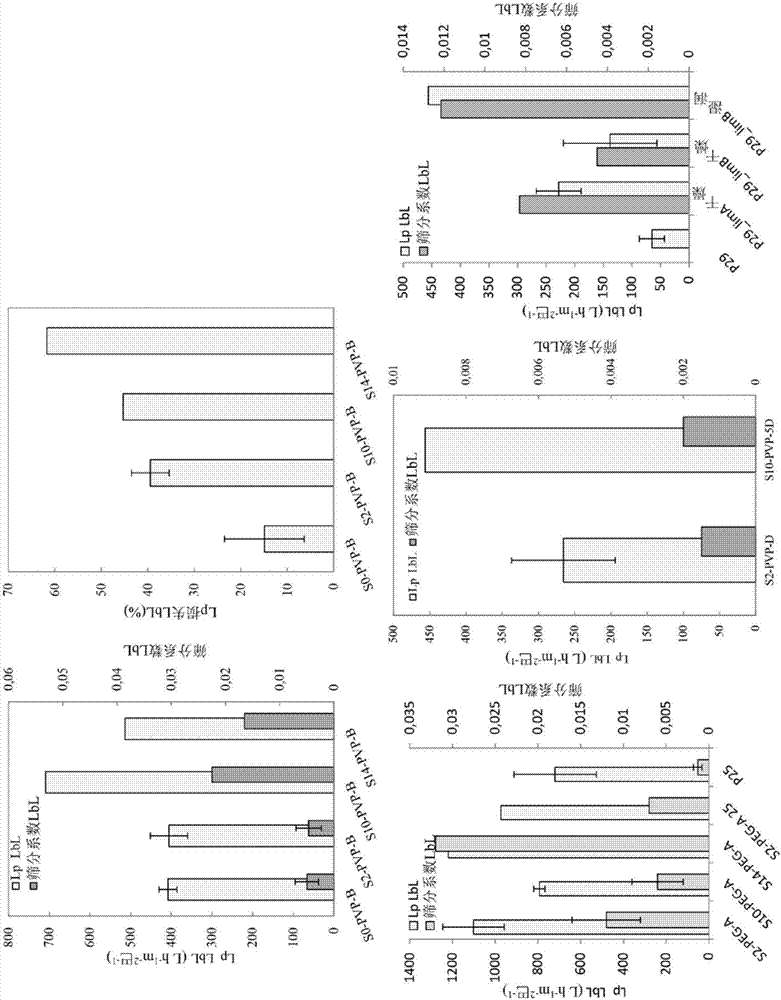

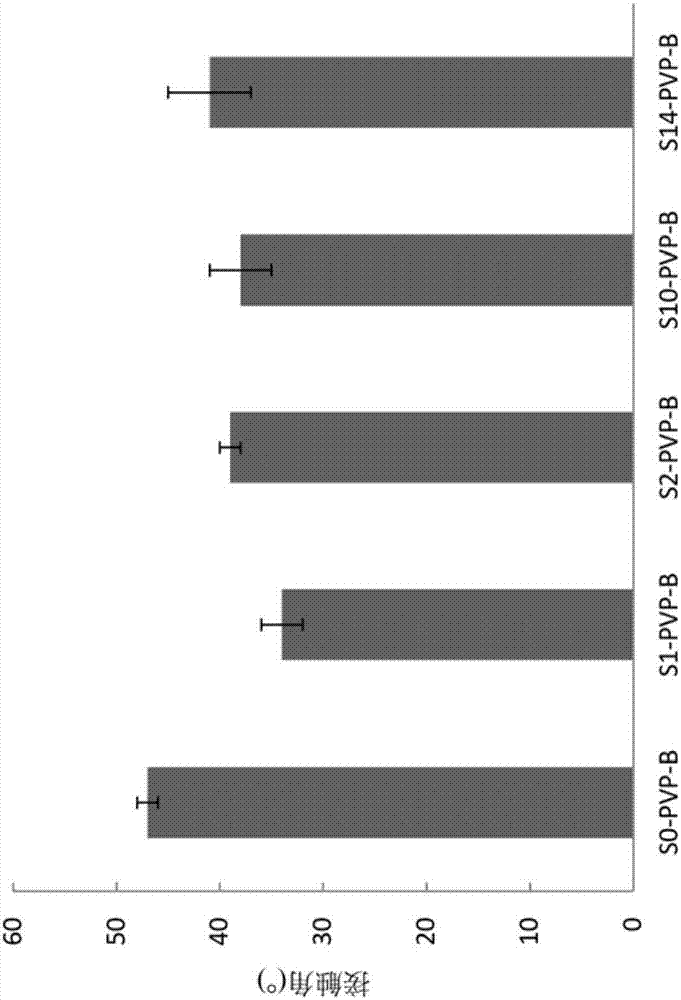

[0093] I. General description of the production of base films with different polymers.

[0094] A casting or spinning solution made of base film-polymer / additive / solvent is produced as follows: First, the selected additive and desired polymer / polymer blend are slowly dissolved in N,N-dimethyl Acetamide [DMAc] and appropriate amount of water (Solution 1).

[0095] The following compounds were used as membrane polymers: polysulfone [PSU] (M n 16-22kDa, M w 40-85kDa), sulfonated polysulfone [SPSU] (M w 50-55kDa, M n 27-32kDa), polyethersulfone [PES] (M w 30-75kDa, M n 16-22kDa), sulfonated polyethersulfone [SPES] (M w 30-35kDa, M n 18-22kDa), polyphenylsulfone [PPSU] (M w 52-55kDa, M n 22kDa), sulfonated polyphenylsulfone [SPPSU] (M w 47-53kDa, M n 17-21 kDa); and mixtures (blends) of these materials.

[0096] Modification of polymers PSU and PES was achieved by post-sulfonation. The polymer is dissolved in dichloromethane under inert gas (concentration 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Molecular mass | aaaaa | aaaaa |

| Molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com