Manufacturing method for polyphenyl sulfone hollow-fiber membrane for use in humidification film

A manufacturing method and technology of polyphenylsulfone, which are applied in the manufacture of final products, chemical characteristics of fibers, chemical instruments and methods, etc., can solve the problems of no record found, no attention to supply humidity and humidification amount, etc. Suppression of segregation and/or cross-linking, high water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

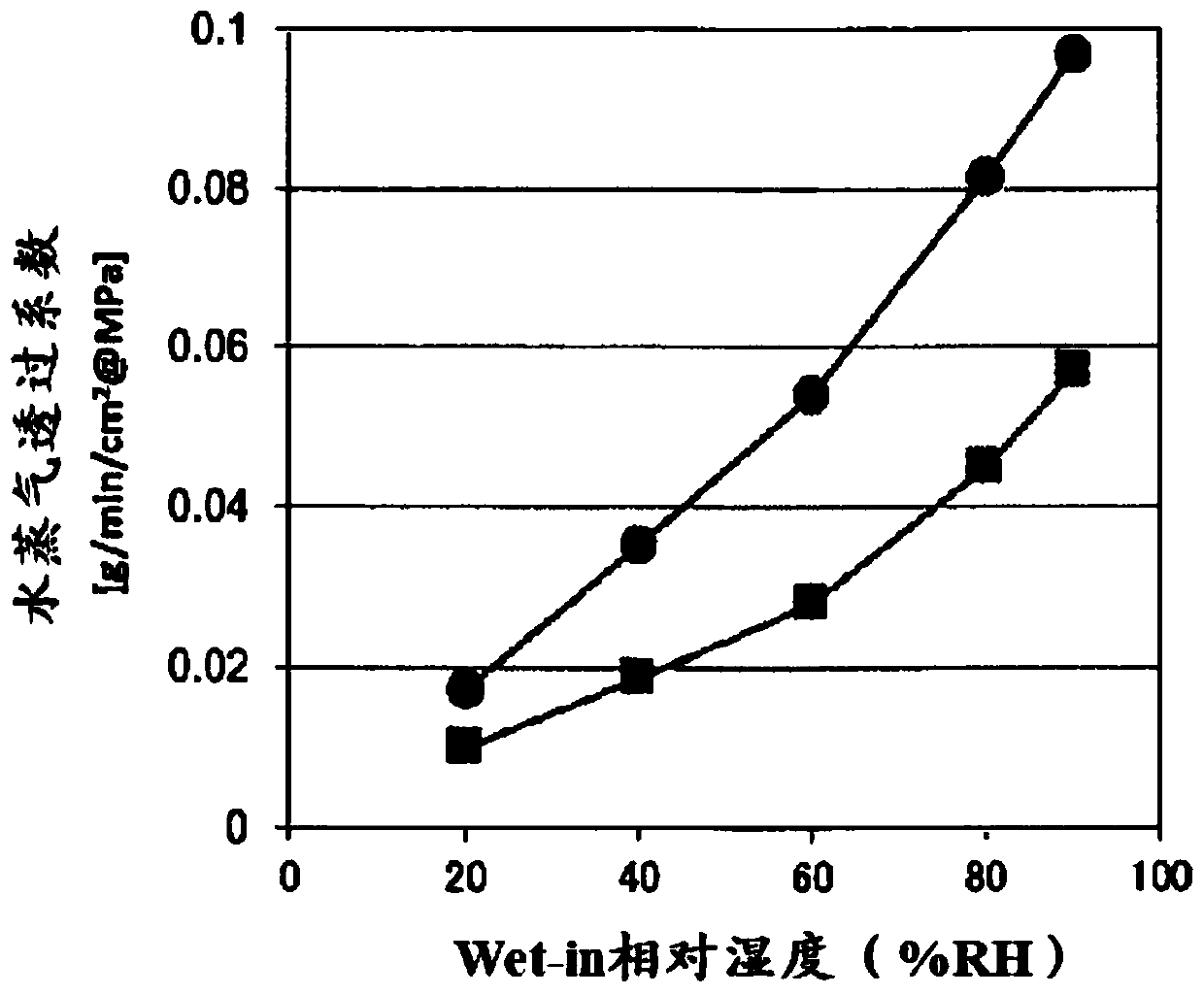

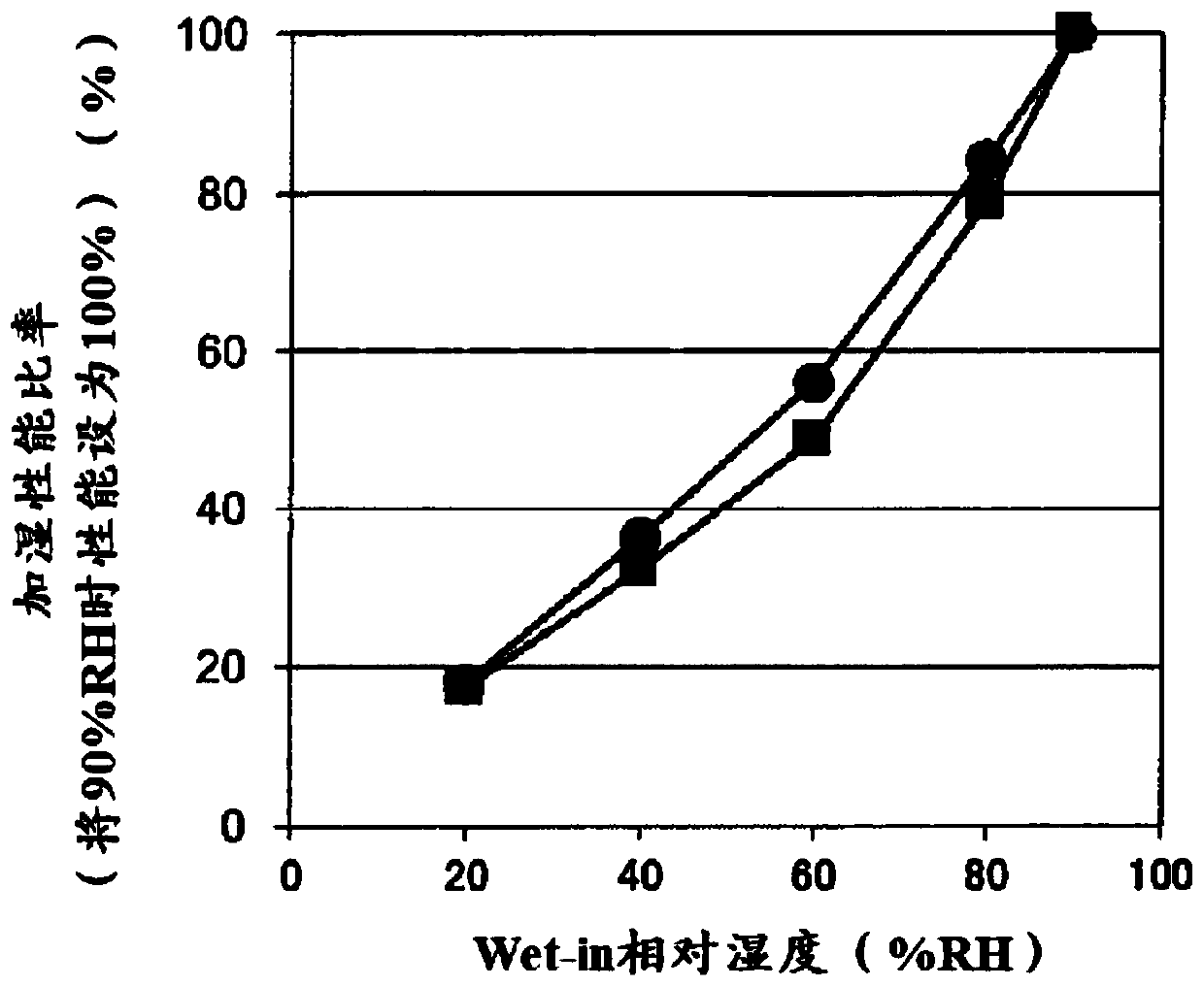

[0030] Next, the present invention will be described using examples.

[0031] Example

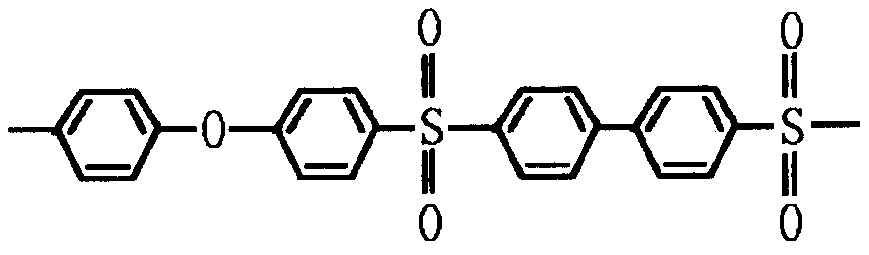

[0032] (1) Using water as the core liquid, 20 parts by weight of polyphenylsulfone (RADEL R-5000 produced by Solvay Specialty Polymers), hydrophilic polyvinylpyrrolidone (K-30G produced by ISP Co.) 15 parts by weight and 65 parts by weight of dimethylacetamide uniform spinning stock solution at room temperature, sprayed from the double ring nozzle into the water coagulation bath, thereafter washed in pressurized water at 121 ° C for 1 hour, and then in Heating in a constant temperature bath at 170° C. for 8 hours and performing cross-linking treatment gave a porous polyphenylsulfone hollow fiber membrane with an outer diameter of 1.0 mm, an inner diameter of 0.7 mm, and a pore diameter of 2.2 nm. Here, the pore size means the average Knudsen diffusion diameter based on the number of samples measured using a nano-perm-porometer manufactured by Seika Digital Image Corporation.

[0033] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com