Blends of polyphenylene sulfones and polyphenylene sulfide

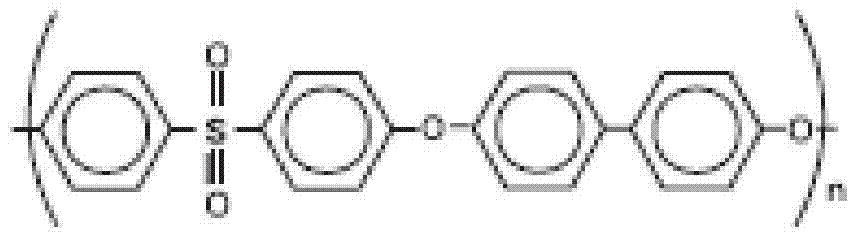

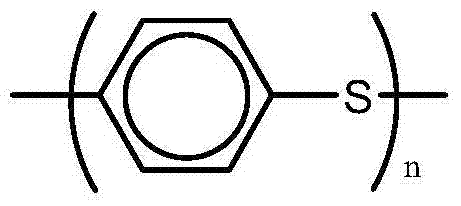

一种聚苯硫醚、聚苯砜的技术,应用在涂层、电气元件、电路等方向,能够解决不相容、材料共混物难混炼、难以制造等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

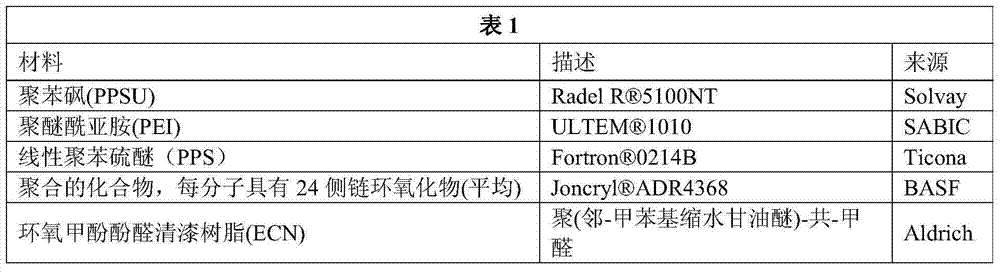

[0051] The purpose of Examples 1-12 was to demonstrate the effect of varying the amount and type of polymeric compatibilizer in compositions with PPSU and PPS resins. Compositions were produced according to the composition preparation procedure described above. Compositions were tested as described above and the results are shown in Tables 2A and 2B.

[0052]

[0053]

[0054] These examples demonstrate the ability to achieve tensile strength greater than or equal to 75 MPa, impact strength greater than or equal to 40 J / m, greater than or equal to 85°C by using only the required amount of Novolac epoxy (ECN) resin to produce A combined composition of a heat distortion temperature and an elongation at break of greater than or equal to 70%. This is effective over a composition range of 25-75 wt% PPSU and 25-75 wt% PPS.

Embodiment 12-23

[0056]The purpose of Examples 12-23 was to demonstrate the effect of varying the amount of novolac epoxy resin and the effect of alternate polymer compounds with pendant epoxy groups in compositions with PPS and PPSU resins. Compositions were produced according to the composition preparation procedure described above. Compositions were tested as described above and the results are shown in Tables 3A and 3B.

[0057]

[0058]

[0059] These examples demonstrate that using only the required amount of epoxy novolak (ECN) resin produces a tensile strength greater than or equal to 75 MPa, an impact strength greater than or equal to 40 J / m, a heat distortion temperature greater than or equal to 85°C and A combined composition having an elongation at break greater than or equal to 70%. This shows that there is an optimal level of ECN epoxy for the composition range of 25-75 wt% PPSU and 25-75 wt% PPS.

Embodiment 24-35

[0061] The purpose of Examples 24-35 was to demonstrate the effect of varying the amount of PEI with PPS as the majority ingredient. Compositions were made according to the two-pass method described above. For compositions containing no epoxy novolac (ECN) resin, only PPS was added to the initial mixture. Compositions were tested as described above and the results are shown in Tables 4A and 4B.

[0062] These results show that the composition can still achieve desired levels of tensile strength, impact strength, HDT and % elongation using increasing amounts of PEI (from 2.5 to 15 wt%) and using 1 wt% epoxy novolac (ECN) resin. Long rate performance.

[0063]

[0064]

[0065] A comparison of Examples 24-35 shows that the compositions comprising PPSU, PPS and PEI have a significant increase in tensile strength, elongation at break and impact strength in the presence of ECN epoxy. The comparative examples show that this improvement is not seen in the examples comprising...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com