Magnet wire insulation comprising a high-temperature sulfone polymer blend

a polymer blend and high-temperature sulfone technology, applied in the direction of insulating conductors/cables, cables, insulated conductors, etc., can solve the problem of expensive polyphenylsulfone resin, and achieve the effect of reducing the amount of expensive resins, strong electrical insulation, and high performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

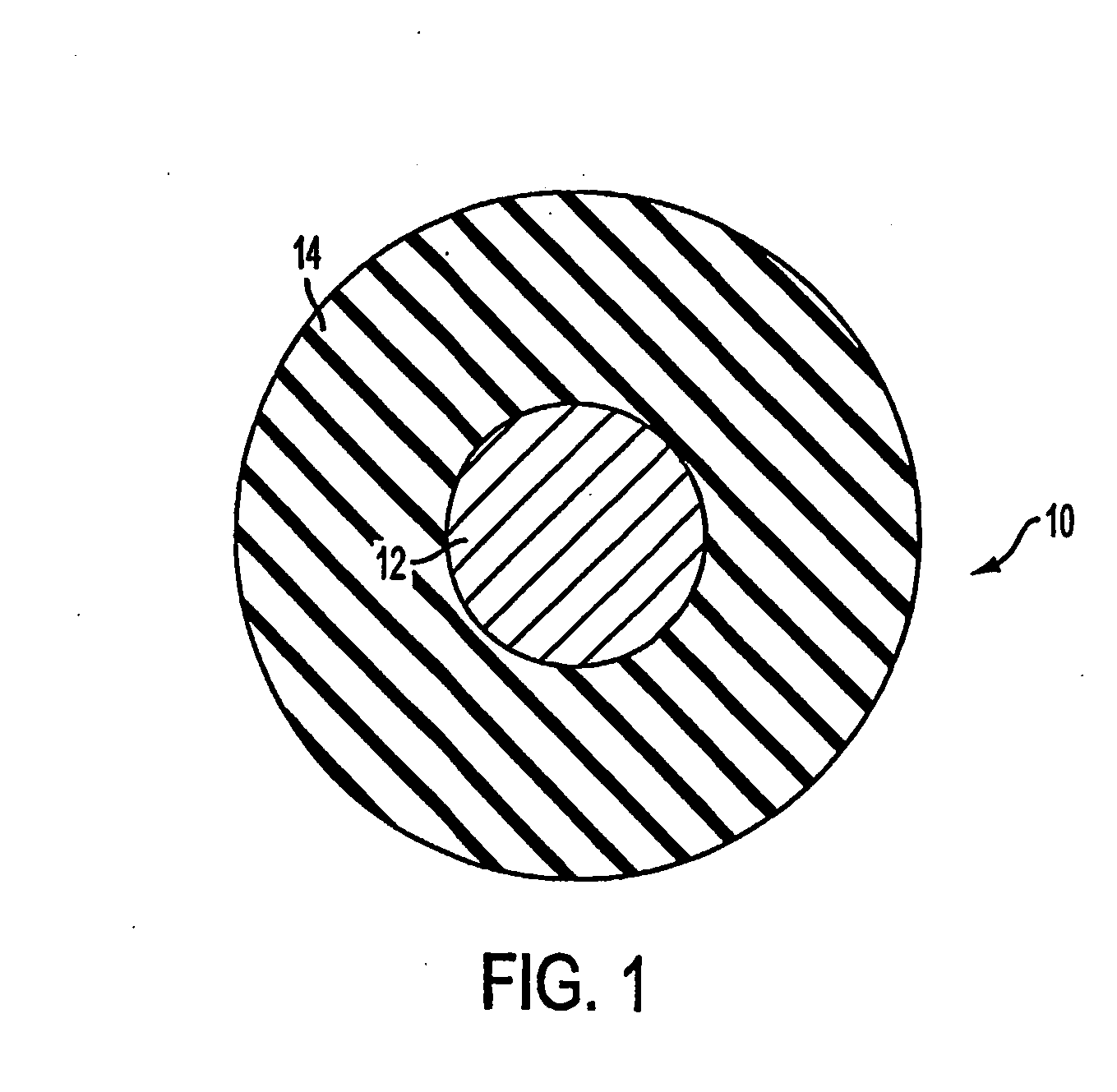

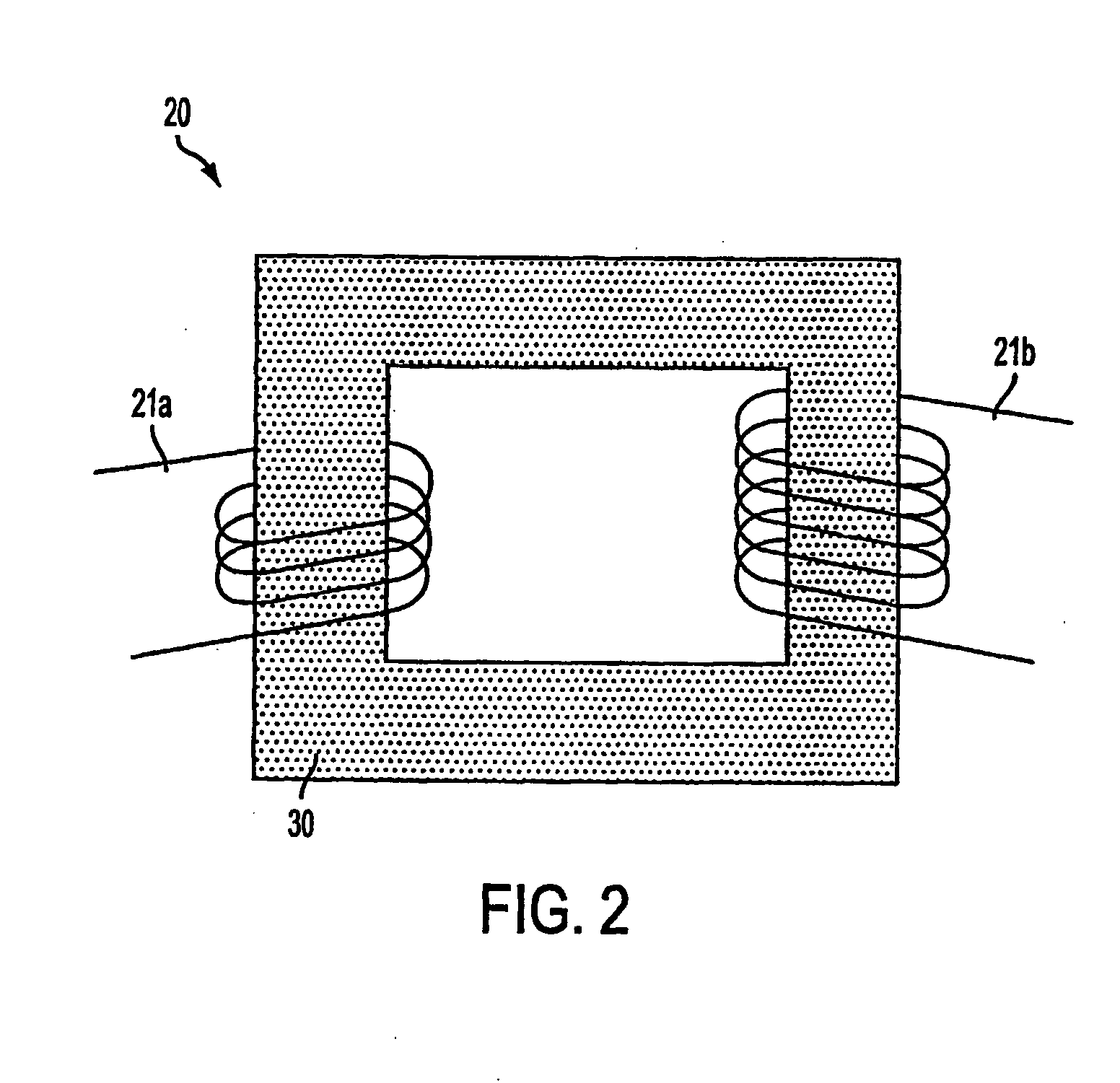

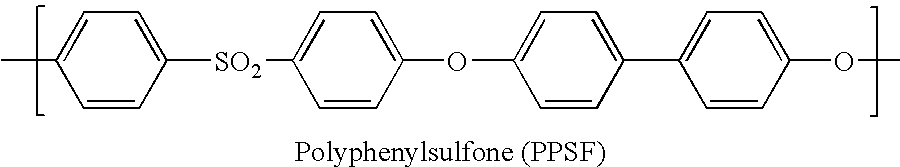

[0014] The present invention provides magnet wire with a robust electrical insulation coating. The present invention provides a high performance poly(aryl ether sulfone) blend which exhibits improved electrical insulation and long term thermal aging stability. The present invention allows for the economical production of a magnet wire comprising a high performance poly(aryl ether sulfone) blend coating with optional amounts of performance and stability additives. The present invention allows for the production of an insulated magnet wire with a reduced amount of an expensive resin, such as PPSF, which retains the high performance properties of PPSF. Coupled with all the above benefits, the present invention allows for the economical fabrication of metallic magnet wire with a thermoplastic blend containing poly(aryl ether sulfones). These benefits are provided by an insulated magnet wire comprising a metallic magnet wire and a polymer composition insulation coating, said polymer comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com