Preparation method of high-purity mannan oligosaccharide

A mannan oligosaccharide and mannanase technology, applied in the field of konjac manna oligosaccharide production, can solve the problem of increasing enzymatic hydrolysis raw material induction and subsequent application instructions, affecting product yield and production cost, and not simplifying and improving the process and other problems, to achieve the effect of reducing cleaning frequency, good anti-fouling ability and high operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

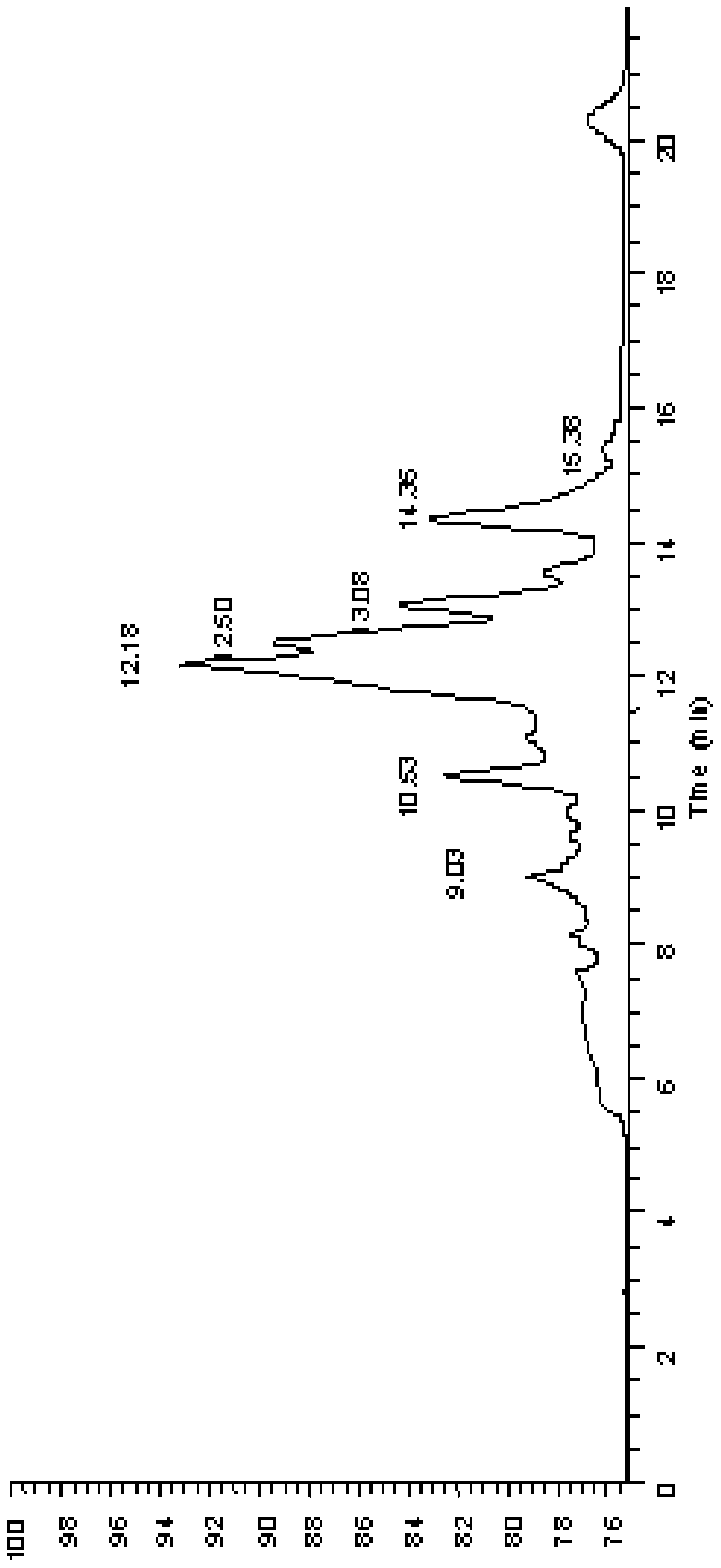

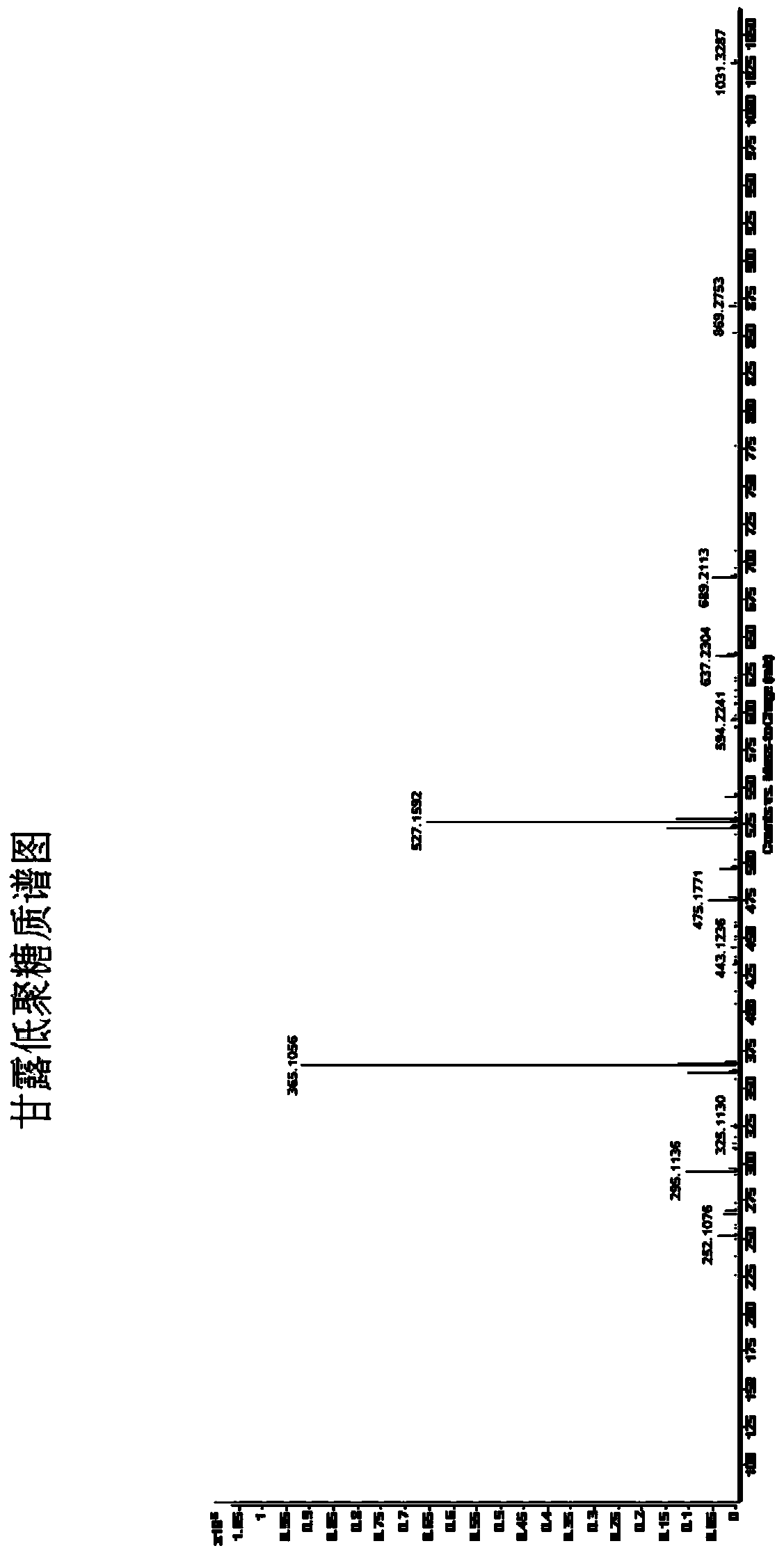

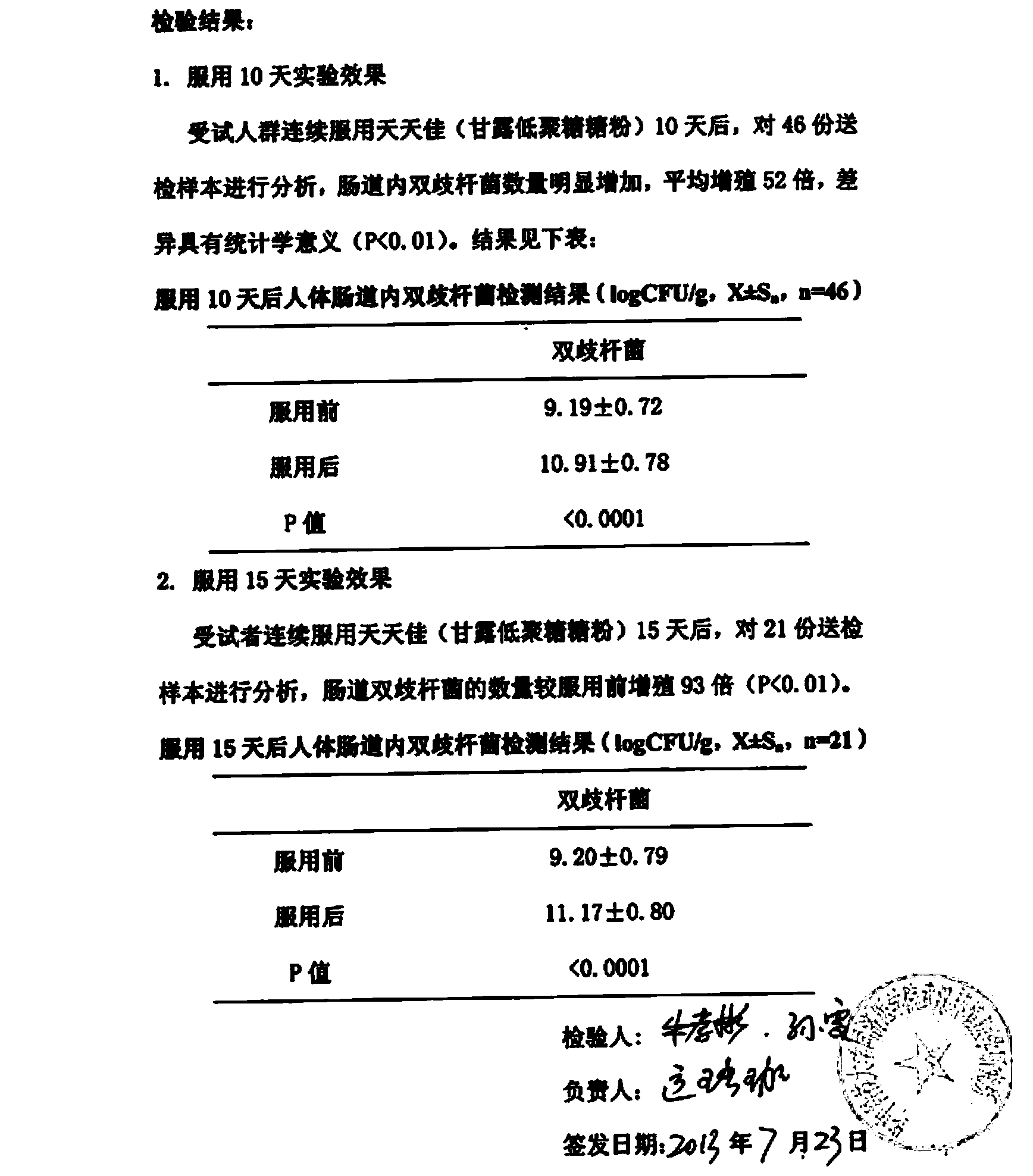

Image

Examples

Embodiment 1

[0047] A preparation method of high-purity mannooligosaccharides, comprising the steps of:

[0048] (1) Manno-oligosaccharide mixture produced by enzymatic hydrolysis and transformation: use Aspergillus niger to ferment to produce highly active neutral β-mannanase, the preservation number is: CCTCC NO.M2012554, the enzyme activity is as high as 5000-8000μmol / ml The solution is purified and stored at 0 or 1 or 2 or 3 or 4 or 5°C for use. Add 2 tons of water to a 5-ton enzymatic hydrolysis tank, heat it to 55°C with steam, add 4L of neutral β-mannanase enzyme solution, stir for 2 or 3 minutes to activate the enzyme solution, and slowly add the viscosity to 20000mpa.s Konjac fine powder 400kg, add in 1 hour. Keep the enzymolysis temperature at 53 or 54 or 55 or 56 or 57°C, pH6.5, enzymolysis time or 2 or 3 or 4 hours, stop enzymolysis when the viscosity of the mannan-oligosaccharide mixture is 40mpa.s, and obtain the oligosaccharide mixture , wherein the biotransformation rate ...

Embodiment 2

[0063] A preparation method of high-purity mannooligosaccharides, comprising the steps of:

[0064] (1) Manno-oligosaccharide mixture produced by enzymatic hydrolysis and conversion: using Aspergillus niger to ferment to produce a highly active neutral β-mannanase, the preservation number is: CCTCC NO.M2012554, the enzyme activity is as high as 4500 μmol / ml, and the enzyme solution is passed through The purification process is stored at 0-5°C for later use. Add 2.5 tons of water into a 5-ton enzymatic hydrolysis tank, heat it to 54°C with steam, add 4.5L of neutral β-mannanase enzyme solution, stir for 2 to 3 minutes to activate the enzyme solution, and slowly add the viscosity to 20000mpa. s konjac powder 550kg, add in 1 hour. Keep the enzymolysis temperature at 53-56°C, pH6.5, enzymolysis time 3.5 hours, measure the viscosity of the manno-oligosaccharide mixture to 60mpa.s, stop the enzymolysis, and obtain the oligosaccharide mixture, in which the glucomannan in konjac flou...

Embodiment 3

[0080] A preparation method of high-purity mannooligosaccharides, comprising the steps of:

[0081] (1) Manno-oligosaccharide mixture produced by enzymatic hydrolysis and conversion: using Aspergillus niger to ferment to produce a highly active neutral β-mannanase, the preservation number is: CCTCC NO.M2012554, the enzyme activity is as high as 4500 μmol / ml, and the enzyme solution is passed through The purification process is stored at 0-5°C for later use. Add 1.5 tons of water into a 5-ton enzymatic hydrolysis tank, heat it to 53°C with steam, add 2.5L of neutral β-mannanase enzyme solution, stir for 3 minutes to activate the enzyme solution, and slowly add Guar gum 255kg, added in 1 hour. Keep the enzymolysis temperature at 53-57°C, pH 6.0, and enzymolysis time for 4.5 hours to measure the viscosity of the mannan-oligosaccharide mixture to 70mpa. The biotransformation rate is 96%.

[0082] (2) Centrifugal separation:

[0083] Use a horizontal screw centrifuge LW250-1000 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com