Polyamide/COFs hybridized nanofiltration composite membrane and preparation method thereof

A composite membrane and polyamide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low selectivity and low permeability of high-permeability separation membranes, and achieve high water flux and The effect of retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

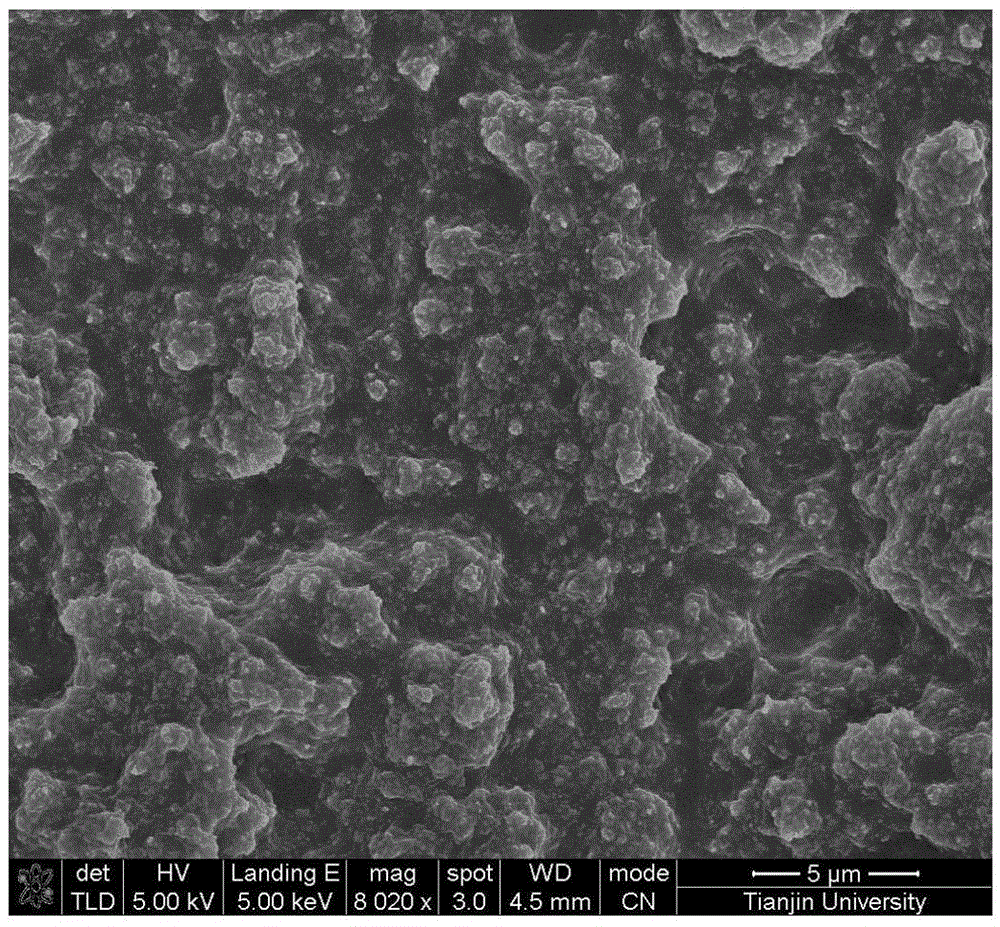

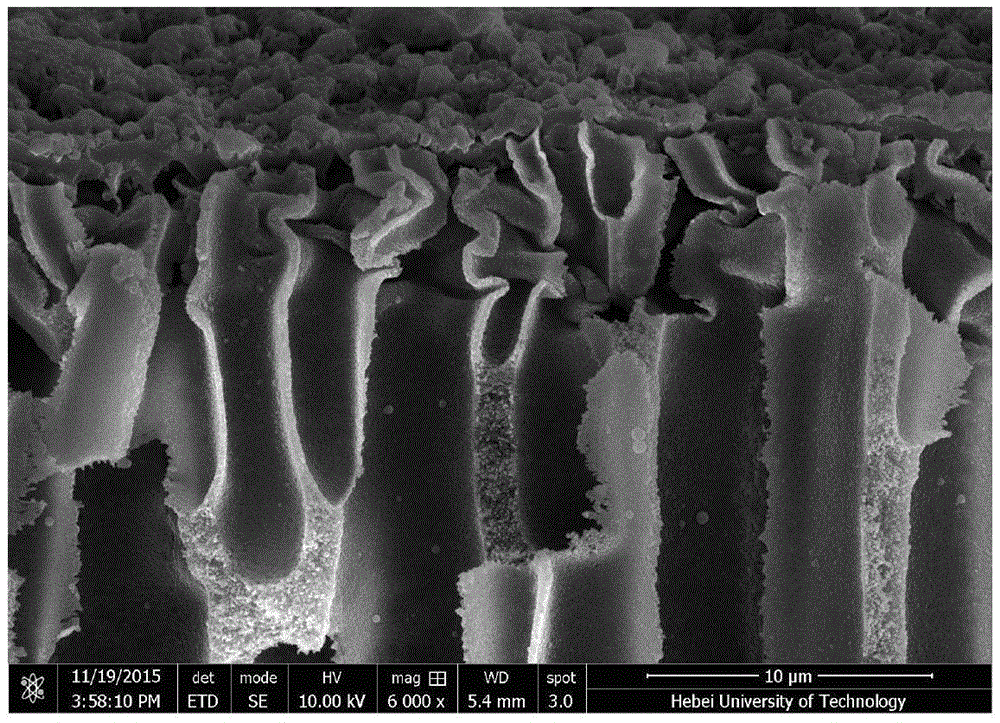

[0033] The porous support layer was prepared by non-solvent-induced phase inversion method: 6.4g polyethersulfone, 6.4g polyethylene glycol (molecular weight 2000) and 27.2g N,N-dimethylformamide were added to a three-necked flask, and the The mixture was stirred for 5 h, and when the stirring time was reached, the mixture was left standing in a water bath at 60° C. for 4 hours to defoam. After degassing, pour the casting solution on a glass plate with a groove depth of 200-400 microns, use a scraper to make a flat liquid film from the casting solution on the glass plate, and then place the obtained liquid film on a gel at room temperature In a water bath (i.e., a water bath), through a phase inversion process, the liquid membrane is solidified into a porous support layer of polyethersulfone sulfone, which is taken out after 2 minutes, and then soaked in deionized water at room temperature for 24 hours to obtain a film with a thickness of 200-400 microns. Polyethersulfone poro...

Embodiment 2-4

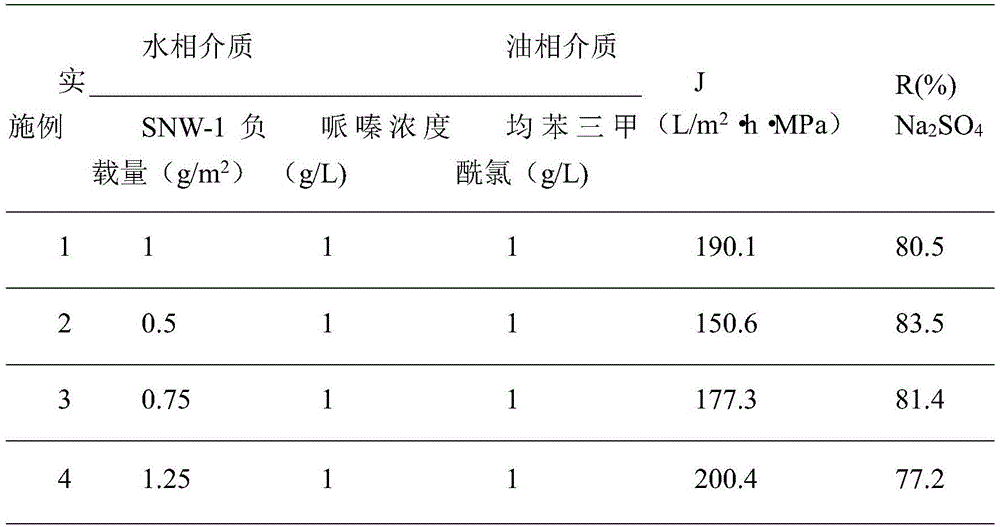

[0041] The content of SNW-1 in the water phase was adjusted, and the rest were the same as in Example 1. The performance test results are shown in Table 1.

[0042]

[0043] Example 1-4 is to investigate the influence of the content of SNW-1 in the aqueous phase on the performance of the nanofiltration membrane obtained.

example 5-7

[0045] Embodiment 5-7 is the same as embodiment 3 except that the concentration of polyamine in water phase is adjusted

[0046]

[0047] Examples 8-10 are to investigate the effect of the concentration of trimesoyl chloride in the oil phase medium on the performance of the prepared SNW-1 / PA nanofiltration composite membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com