Lampblack filtering material comprising porous foam metal and preparation method of lampblack filtering material

A technology of porous metal foam and air filter materials, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of low efficiency of oil fume air purification, high quality of porous ceramics, frequent use and replacement, etc., to achieve obvious antibacterial and antibacterial Mildew effect, good heat resistance, and the effect of improving adsorption and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

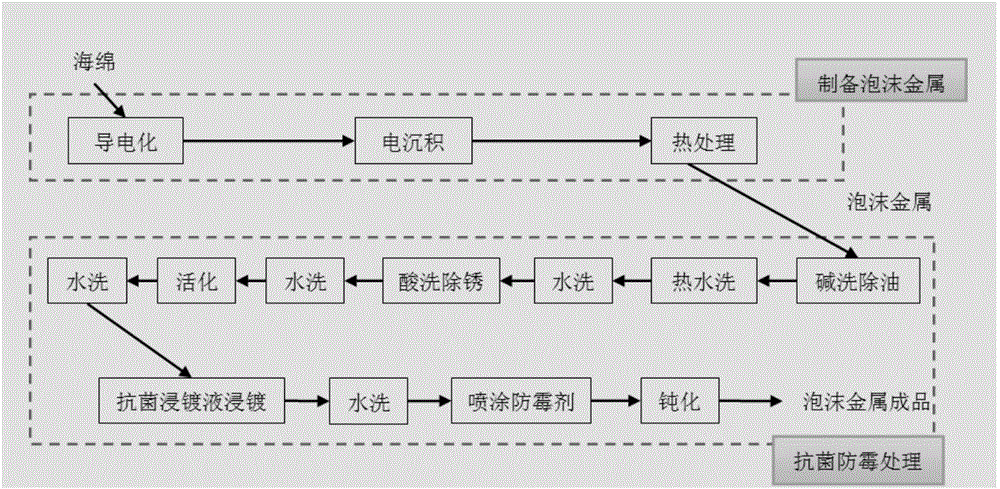

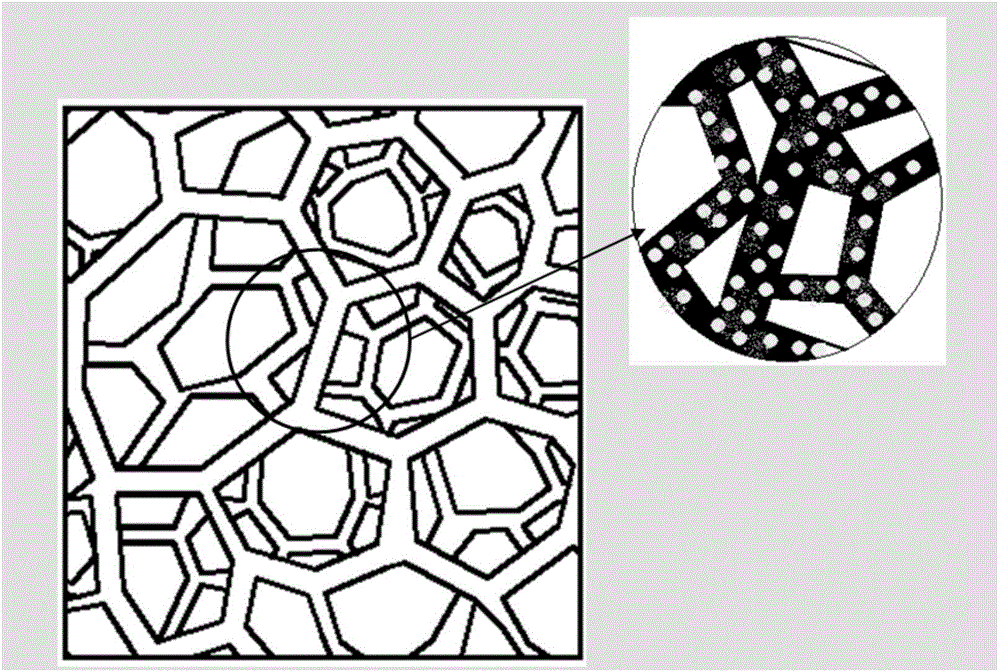

[0045] 1. Prepare foam metal by electrodeposition method:

[0046] First, the continuous polymer sponge is used as the matrix, and the conductive adhesive is applied to the conductive treatment. After removing the film, pressing uniformly, drying and curing, the sulfamate system is used to treat it at a temperature of 40-50 °C. Conduct electroplating, then oxidize at 600°C for 12 minutes, remove the substrate sponge, and reduce and sinter at 900°C for 40 minutes in a hydrogen atmosphere to obtain porous iron foam with a pore size of 45 PPI and a porosity of about 97.5%.

[0047] 2. Treatment of porous metal foam

[0048]Soak the obtained porous foam iron in lye degreasing solution at 50~55℃ for 18~20 minutes, rinse with hot water once, wash with warm water for 2~3 times, and then use 10g / l hydrochloric acid at 20~25℃. Soak at ℃ for 12 to 15 minutes, wash with water 2 to 3 times, and then immerse in colloidal palladium activation solution for 5 to 10 minutes.

[0049] 3. Anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wind resistance | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com