Heat treatment process improving high strength wrought magnesium alloy damping performance

A deformed magnesium alloy, high-strength technology, applied in the field of heat treatment technology, can solve the problems of material performance failure and complicated process, and achieve the effect of guaranteed mechanical properties, simple and mature process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A heat treatment process method for improving the damping performance of a high-strength deformed magnesium alloy, the heat treatment process comprising the following steps:

[0025] (1) Magnesium alloy raw materials used: common commercial AZ61 high-strength deformed magnesium alloy ingots are used as raw materials, the alloy composition (weight percentage) is: 5.81% Al, 0.55% Zn, 0.29% Mn, impurity elements are less than 0.02% , and the rest are Mg.

[0026] (2) Homogenization treatment of magnesium alloy ingots: the homogenization treatment of magnesium alloy ingots is carried out in a heat treatment furnace, and the process parameters are: temperature 390° C., time 8 hours.

[0027] (3) Extrusion plastic deformation: Extrude the homogenized magnesium alloy ingot on an extruder, the process parameters are: extrusion temperature 350°C, extrusion ratio 11, extrusion speed 5m / min, And the speed is constant.

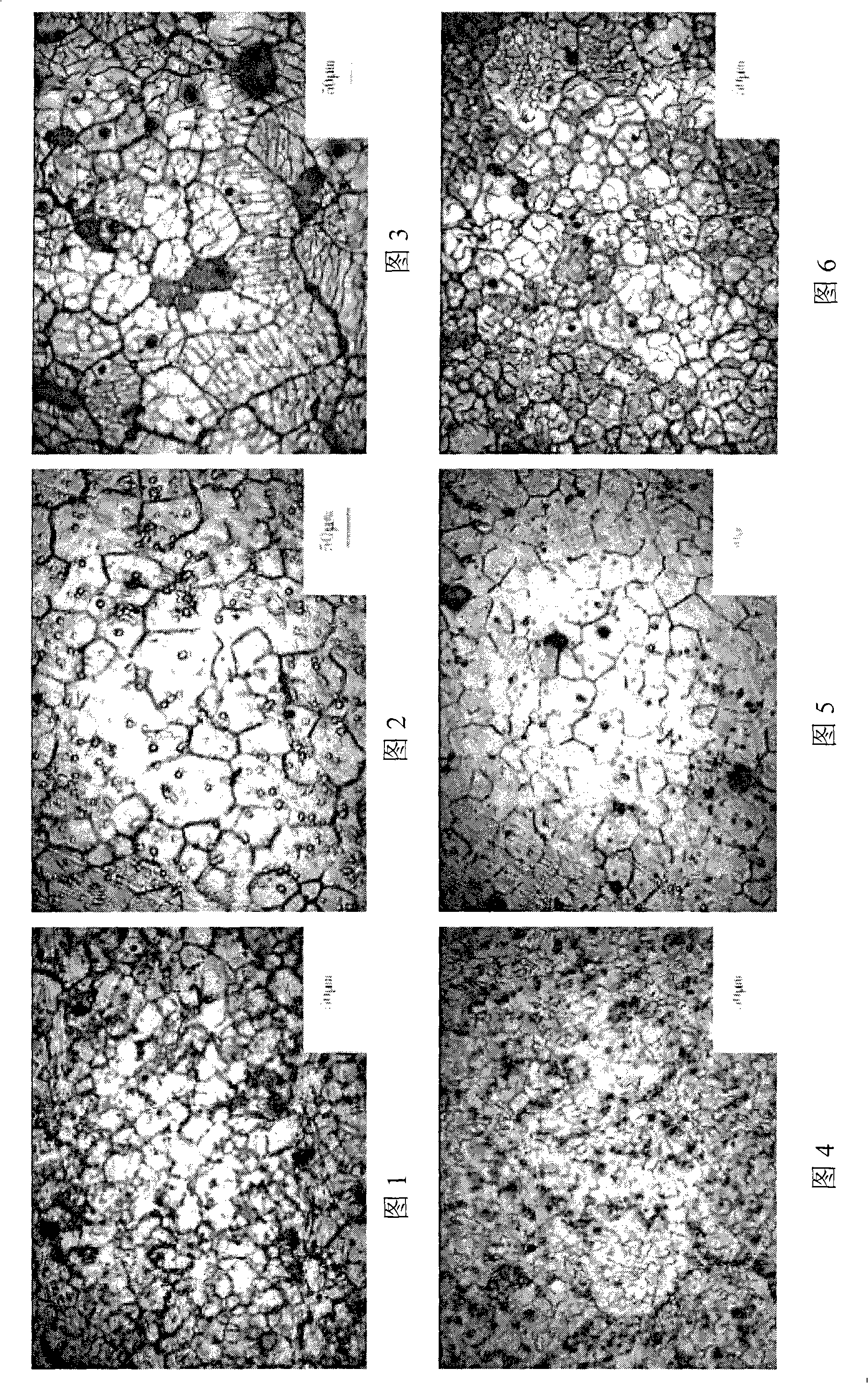

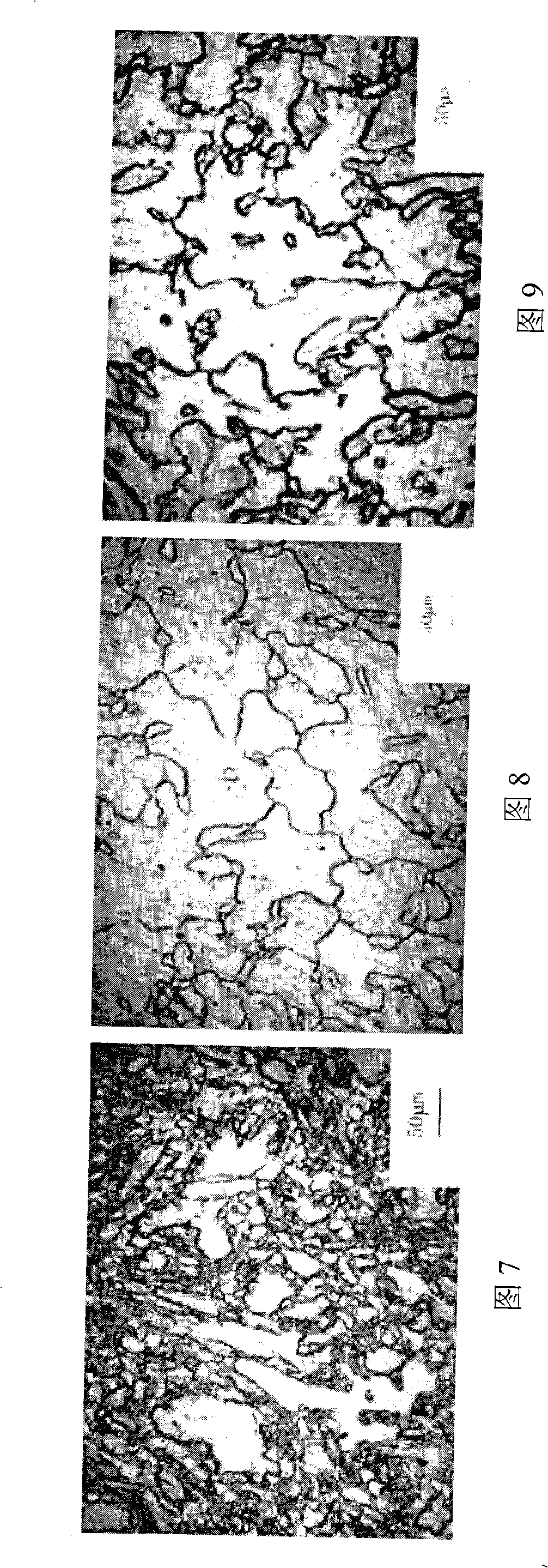

[0028] Figure 1 is a photo of the metallograp...

Embodiment 2

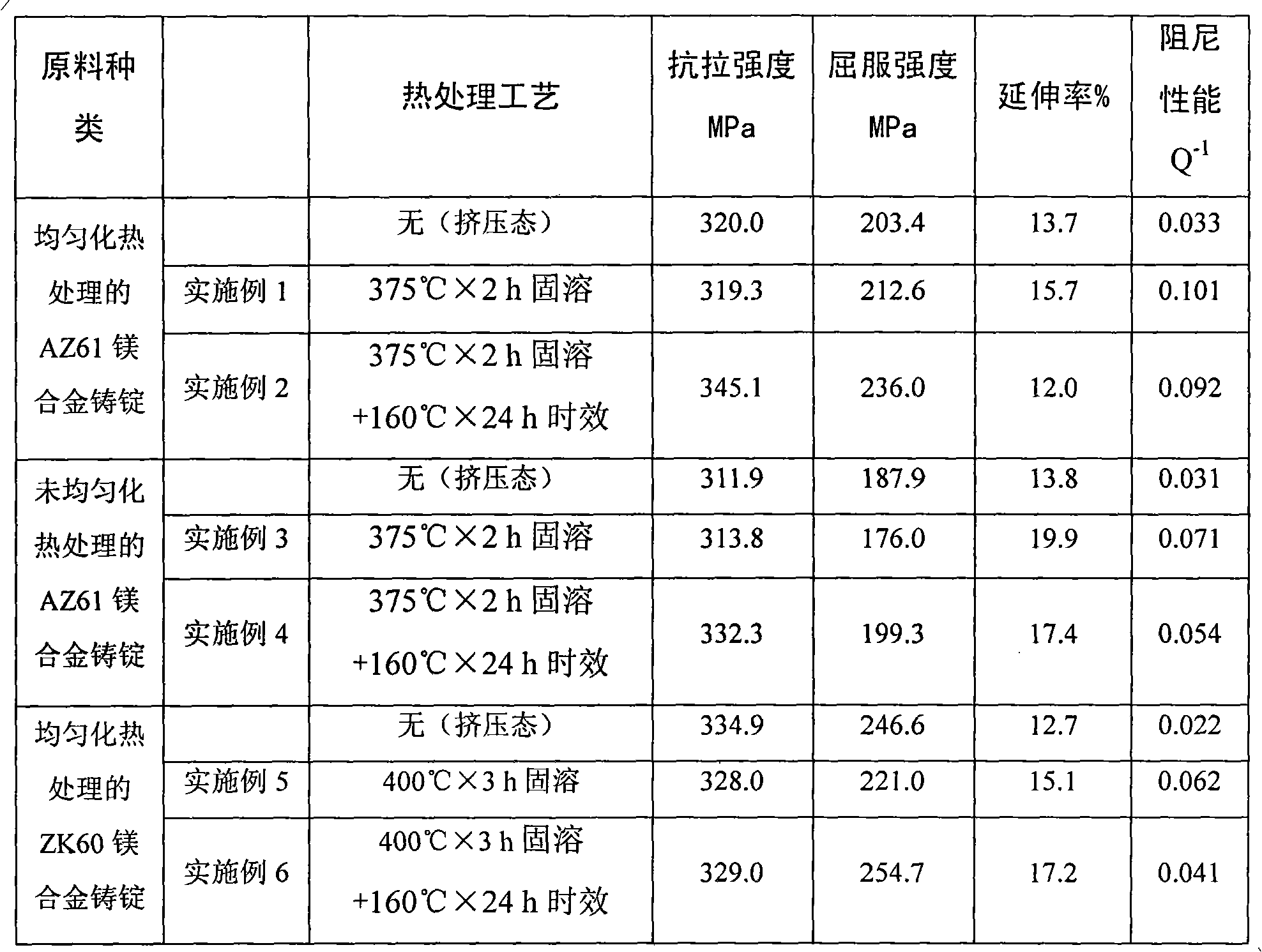

[0032] Embodiment 2: The same magnesium alloy raw material, magnesium alloy ingot homogenization treatment, extrusion plastic deformation, solution heat treatment process as in embodiment 1 are used, and the process parameters are completely the same. The difference is that the deformed magnesium alloy after the solution heat treatment described in Example 1 is subjected to aging heat treatment again, and the process parameters are: heating to 160° C., holding the temperature for 24 hours, and air cooling to room temperature.

[0033] The AZ61 wrought magnesium alloy obtained through the treatment of Example 2 has a tensile strength of 345.1MPa at room temperature, a yield strength of 236.0MPa, and an elongation of 12.0%; at a frequency of 1Hz and a strain amplitude of 3.5×10 -3 When, the damping performance Q of the alloy -1 = 0.092.

[0034] Since the damping of magnesium alloys is mainly caused by the dislocation mechanism, it is generally believed that the mechanical prop...

Embodiment 3

[0035] Example 3: The difference from Example 1 is that the homogenization treatment of the magnesium alloy ingot is not implemented. The magnesium alloy raw material, extrusion plastic deformation and solution heat treatment process used in this embodiment are the same as those in Embodiment 1, and the process parameters are also consistent.

[0036] The metallographic structure of the AZ61 deformed magnesium alloy after extrusion plastic deformation in this example is shown in Figure 4. Compared with Figure 1, it can be seen that the grains in Figure 4 are relatively small, which is due to the lack of homogenization treatment before extrusion . The tensile strength of the AZ61 deformed magnesium alloy after extrusion plastic deformation at room temperature is 311.9MPa, the yield strength is 187.9MPa, and the elongation is 13.8%; at a frequency of 1Hz and a strain amplitude of 3.5×10 -3 When, the damping performance Q of the alloy -1 = 0.031.

[0037] In this embodiment, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com