High-damping and high-strength Mg-Cu-Mn-Zn-Y alloy and manufacturing method thereof

A high damping and alloy technology, applied in the field of high damping and high strength Mg-Cu-Mn-Zn-Y alloy and its manufacturing, can solve the problems of limited application range, poor corrosion resistance, damage dislocation mechanism, etc., and achieve a simple and mature process , strong portability and wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0029] Embodiment 1: The high-damping high-strength magnesium alloy of this embodiment is a Mg-Cu-Mn-Zn-Y alloy, and the weight percentages of each component are: Cu=2.2%, Mn=0.8%, Y=0.5%, Zn =1.5%, the unavoidable impurities are Si and Fe, the total amount of which is <0.1%, and the balance is magnesium. Put industrially pure magnesium with a purity greater than 99.9% into a ceramic crucible preheated to 300°C for heating and melting, and pass through argon for protection. At 700°C, according to the weight percentage Cu=2.8%, Mn=0.9%, Y=0.5%, Zn=1.5% Add alloy elements. Wherein Cu, Mn, Y and Zn are respectively added in the form of Mg-30wt.% Cu master alloy, Mg-4.1wt.% Mn master alloy, Mg-30.30wt.% Y master alloy and pure Zn. Continue to heat up to 850°C, keep warm and stir to fully melt the intermediate alloy. After the alloy is completely melted, keep it at 850°C for 3 minutes; add refining agent for 3 minutes of refining treatment, and then stand at 750°C for 10 minutes a...

specific Embodiment approach 2

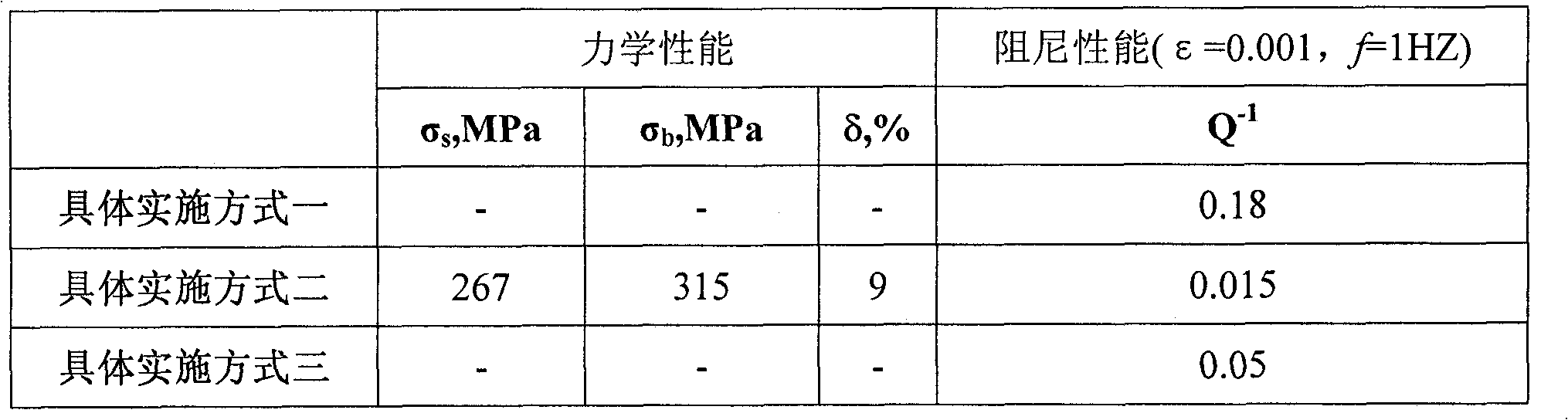

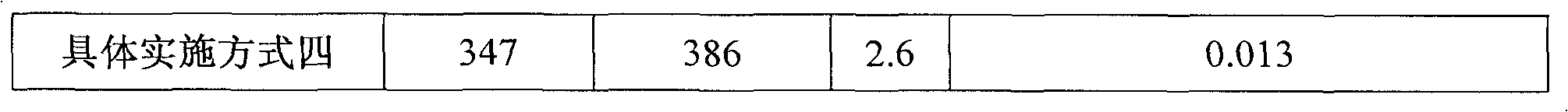

[0030] Embodiment 2: The smelted magnesium alloy ingot is subjected to homogenization treatment, and the process parameters are: temperature 380° C., time 15 hours. After the homogenization treatment, the magnesium alloy ingot is subjected to conventional hot extrusion, the extrusion temperature is 350° C., the extrusion ratio is 20-25, and the extrusion speed is constant. The properties of the magnesium alloy are shown in Table 1, where the damping performance refers to the room temperature damping performance of the alloy under the conditions of a strain amplitude of 0.001 and a vibration frequency of 1HZ.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 is that after pure magnesium is melted and heated to 700°C, according to the weight percentage Cu=2.4%, Mn=1.0%, Y=1.9%, Zn=4.7% Add alloying elements. The properties of the magnesium alloy are shown in Table 1, where the damping performance refers to the room temperature damping performance of the alloy under the conditions of a strain amplitude of 0.001 and a vibration frequency of 1HZ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com