Method for preparing nano quantum dot level Fe3O4 superparamagnetic particles

A technology of superparamagnetic particles and nano-quantum dots is applied in the preparation of nano-quantum dot-level Fe3O4 superparamagnetic particles and the field of preparation of Fe3O4 superparamagnetic particles, which can solve the problem of high requirements for preparation conditions, long synthesis period and high price. and other problems, to achieve the effect of simple and mature process, short reaction period and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

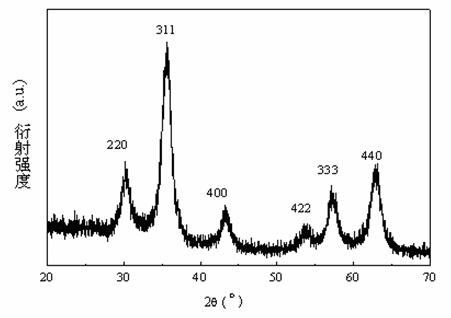

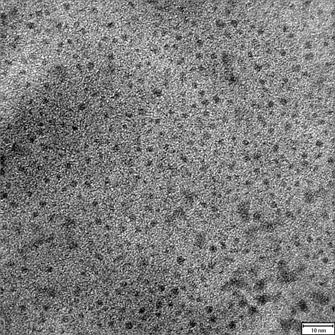

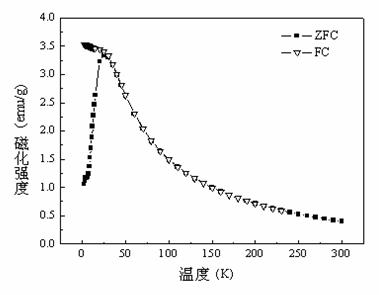

[0025] Weigh 0.4043 g metal precursor Fe(NO 3 ) 3 9H 2 O was added to a three-necked flask containing 100 mL of triethylene glycol, condensed and refluxed at 100 °C for 30 min, and continued to heat up to 250 °C and kept at this temperature for 30 min to obtain 2.8 nm Fe 3 o 4 colloid. From image 3 It can be seen that the obtained Fe 3 o 4 Quantum dots exhibit ferromagnetism below 25 K, and superparamagnetism when the temperature exceeds 25 K; from Figure 4 It can be seen that the obtained Fe 3 o 4 The magnetization curve of quantum dots crosses zero, the coercive force is zero, and the remanent magnetization is zero, indicating that it has superparamagnetism at room temperature.

Embodiment 2

[0027] Weigh 0.8080 g metal precursor Fe(NO 3 ) 3 9H 2 Add O into a three-necked flask containing 100 mL of diethylene glycol, condense and reflux at 100 °C for 30 min, continue to raise the temperature to 250 °C and keep at this temperature for 30 min to obtain Fe 3 o 4 colloid.

Embodiment 3

[0029] Weigh 1.2121 g metal precursor Fe(NO 3 ) 3 9H 2 O was added to a three-necked flask containing 100 mL of triethylene glycol, condensed and refluxed at a temperature of 100 °C for 30 min, continued to heat up to 230 °C and kept at this temperature for 60 min to obtain Fe 3 o 4 colloid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com