Central frequency adjustable substrate integrated waveguide filter and manufacturing method thereof

A substrate-integrated waveguide and center frequency technology, applied in the filter field, can solve the problems of large loss, low integration, and no small filter modules, etc., to achieve reduced loss, high reliability, increased convenience and possibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

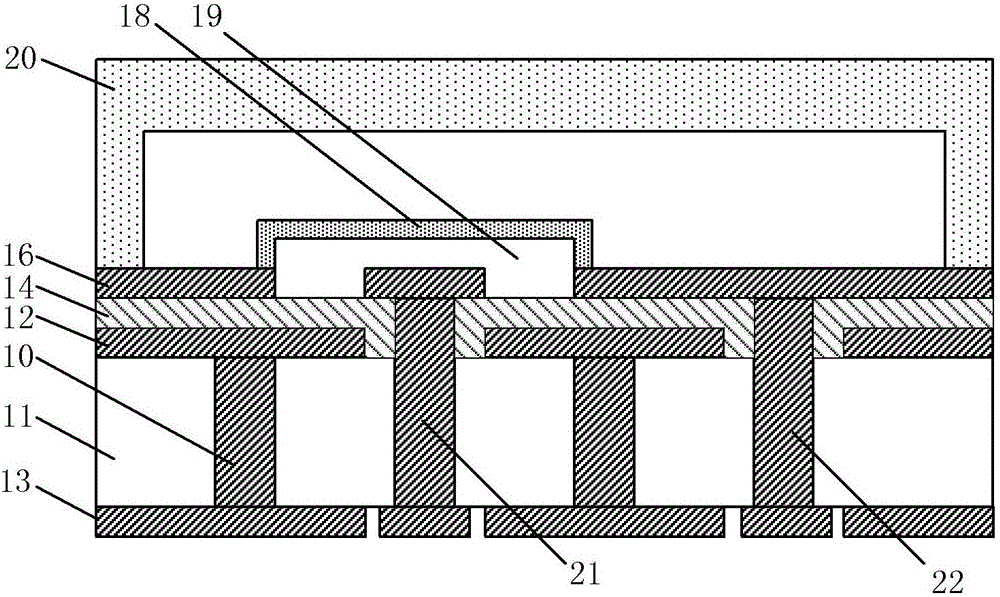

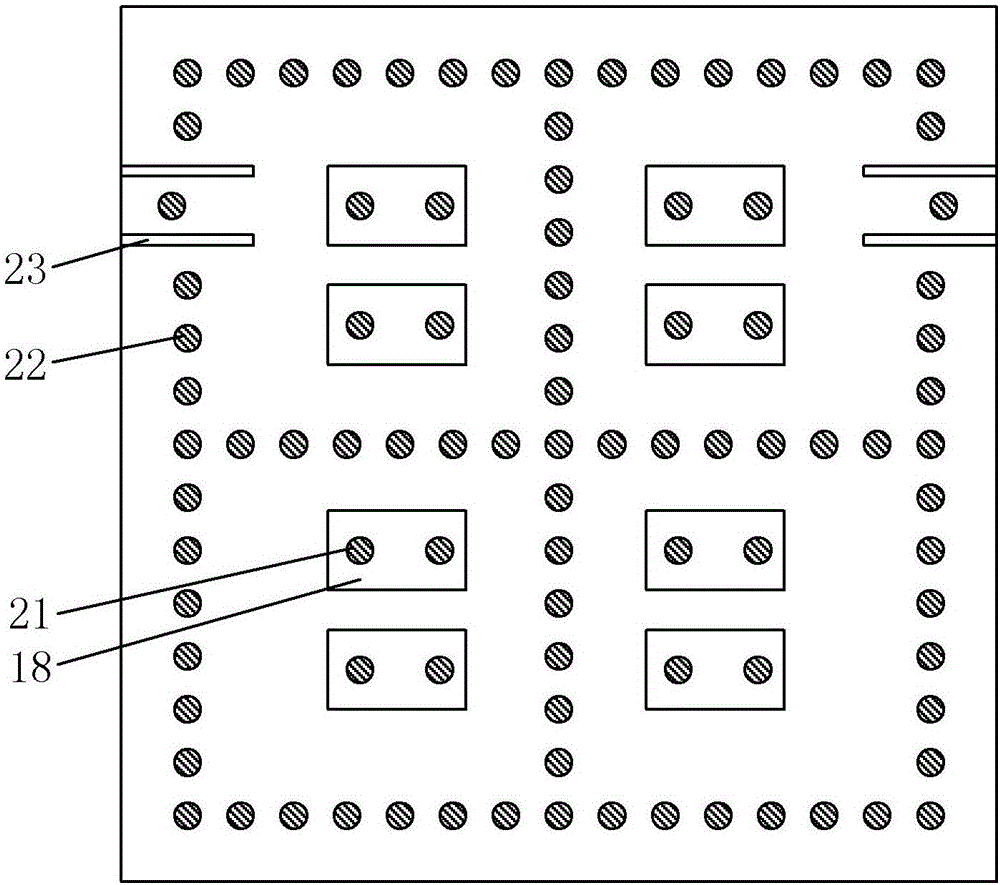

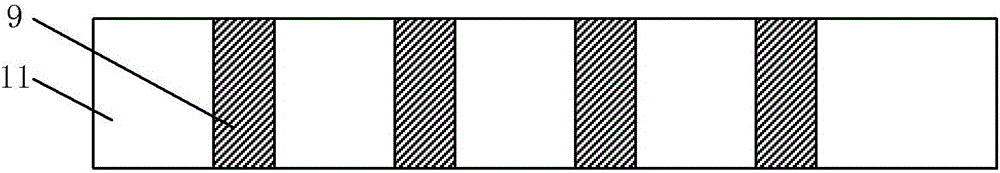

[0028] In general, the present invention proposes a substrate-integrated waveguide filter with adjustable center frequency. According to the method of electrical adjustment of the waveguide resonant frequency, the conductive column is loaded in the filter resonant cavity, and the switch of the conductive column is realized through the conductive film bridge to realize the disturbance of the resonant frequency of the resonant cavity, thereby realizing the substrate integrated waveguide filter The adjustment of the center frequency of the filter greatly increases the application range and calibrability of the filter.

[0029] In terms of the manufacturing method, the present invention utilizes the MEMS process to manufacture the conductive film bridge, that is, the present invention uses the conductive film bridge switch to adjust the center frequency of the substrate integrated waveguide filter through the manufacturing method of the MEMS process and the wafer-level process. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com