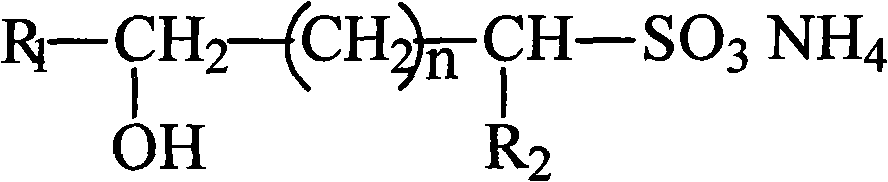

Nanometer silicon dioxide modified sulphonate oil-displacing agent and preparation method thereof

A nano-silica, silica technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of scaling in the ground injection system, unfavorable residual oil recovery, difficulty in crude oil demulsification, etc. High activity, easy biodegradation, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

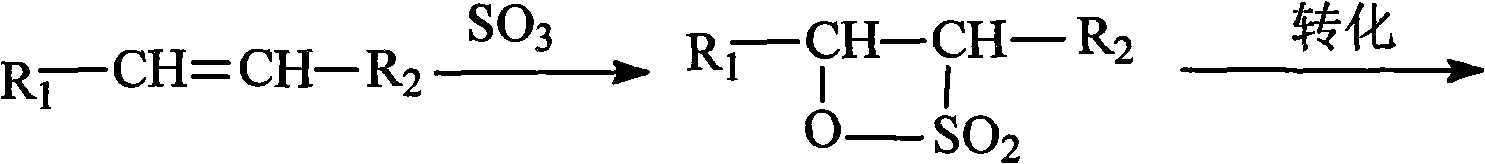

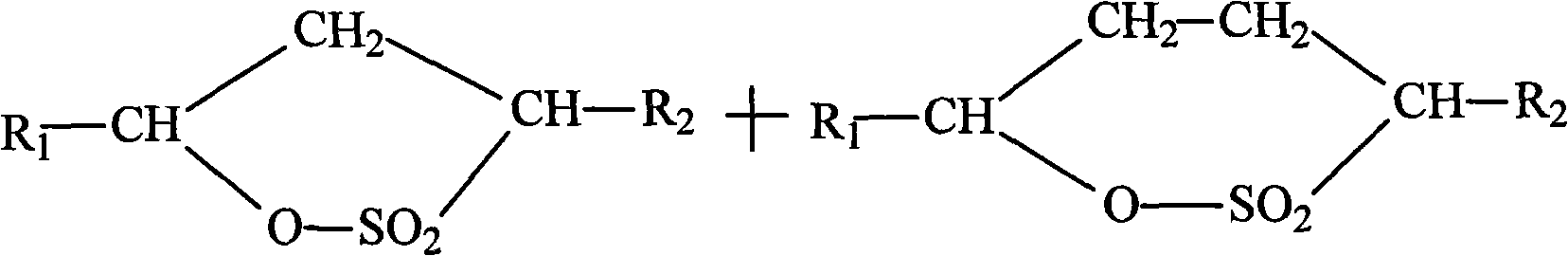

Method used

Image

Examples

Embodiment Construction

[0016] Preparation of the oil displacement agent of the present invention: Naphthenic oil and fuming concentrated sulfuric acid are added into the reaction kettle according to the mass ratio of 5:1 to 2.5:1, and the temperature is raised to 10°C to 80°C for sulfonation Reaction, the reaction time is 1 to 10 hours. After the sulfonation reaction is completed, neutralize the material with alkaline water until the material is weakly alkaline to obtain a naphthene sulfonate; according to the total mass parts of the naphthene sulfonate, the total mass part is 60-90, and the nanometer silicon dioxide accounts for the total mass part The number is 10-40, put into the reaction kettle; raise the temperature to 20°C-50°C, stir for 1-4 hours, and obtain the oil-displacing agent of the present invention.

[0017] Application of the oil-displacing agent of the present invention: the total mass fraction of the oil-displacing agent is 0.3-0.4, i.e. 4000mg.L -1 ; The oil-water system is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com