Leadless piezoelectric ceramics and method for preparing the same

A lead-free piezoelectric and ceramic technology, used in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

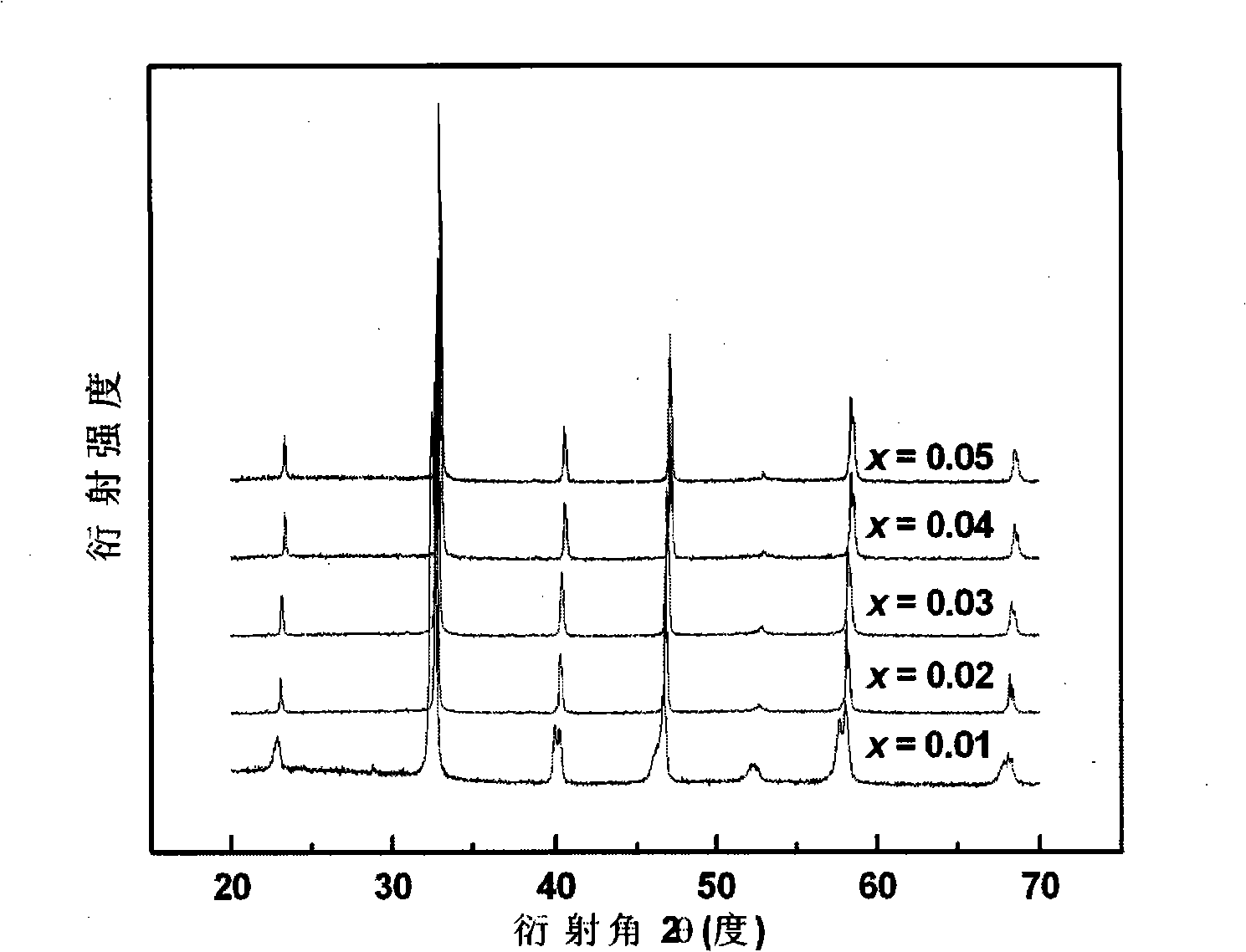

Embodiment 1

[0022] The first step: first determine the value of x, here x=0.01, 0.02, 0.03, 0.04, 0.05. According to the chemical formula 0.94BNT-(0.06-x)BT-xKNN, for each determined value of x, that is, each component, weigh the dried Bi with a purity greater than 99.0% 2 o 3 、Na 2 CO 3 、TiO 2 、BaCO 3 , Nb 2 o 5 and K with a purity of 98.0% 2 CO 3 Raw powder. After considering the purity, the weight of each original powder corresponding to each component is as follows (unit: gram):

[0023] Bi 2 o 3

Na 2 CO 3

TiO 2

BaCO 3

K 2 CO 3

Nb 2 o 5

x=0.01

10.0607

2.5223

7.9900

0.9967

0.0353

0.1329

x=0.02

10.0607

2.5489

7.9093

0.7973

0.0705

0.2658

x=0.03

10.0607

2.5754

7.8286

0.5980

0.1058

0.3988

x=0.04

10.0607

2.6020

7.7479

0.3987

0.1410

0.5317

x=0.05

10.0607

2.6285

7.66...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com