Drilling equipment used for machine parts

A technology for mechanical parts and drilling equipment, applied in drilling/drilling equipment, metal processing mechanical parts, metal processing equipment, etc., can solve problems such as metal chip scratches, and achieve the effect of simplifying the structure and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

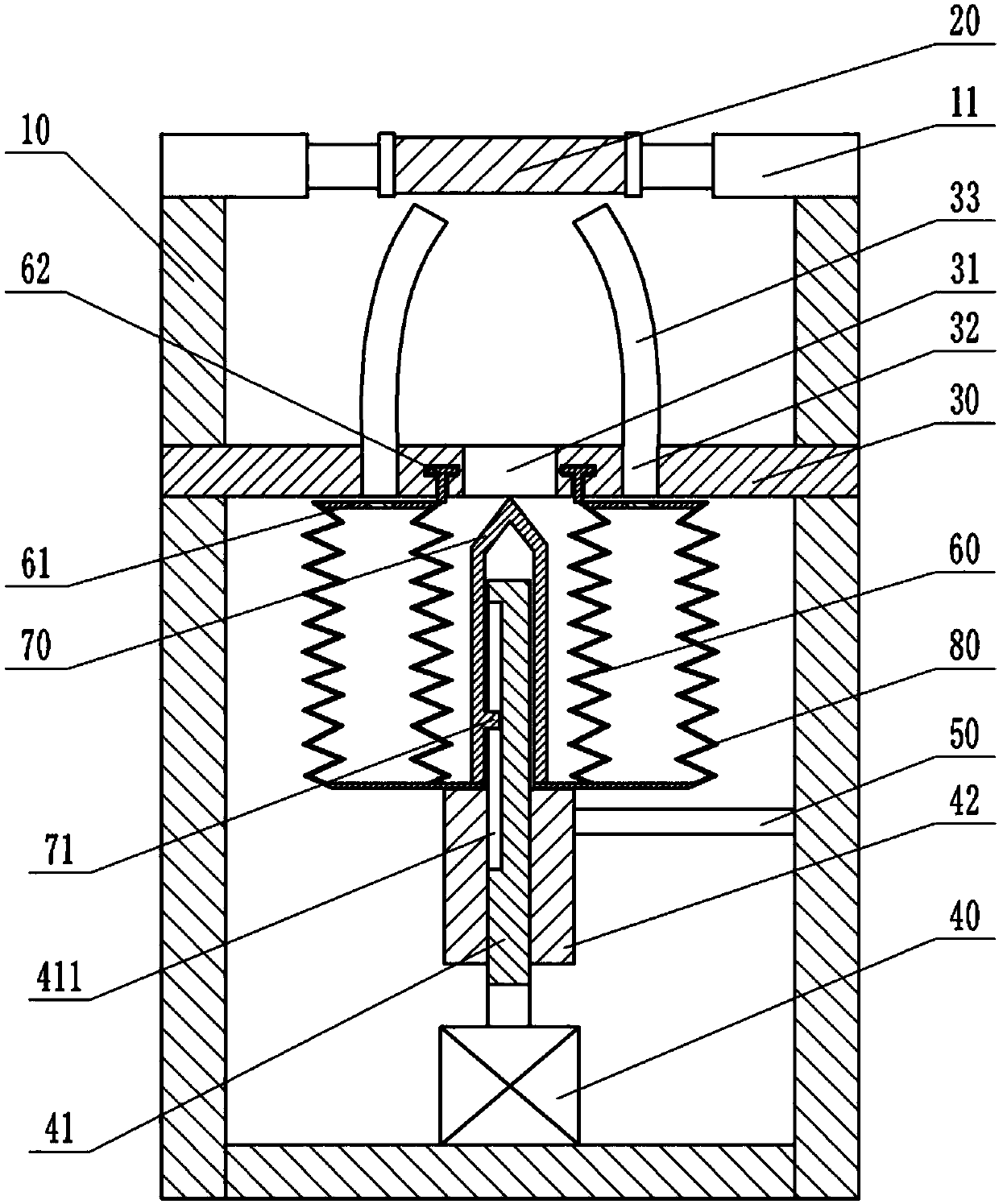

[0019] Instructions attached figure 1 The marks include: frame 10, clamping cylinder 11, mechanical parts 20, horizontal plate 30, through hole 31, vent hole 32, air guide pipe 33, motor 40, threaded rod 41, strip groove 411, push sleeve 42, limit Position bar 50, rigid corrugated pipe 60, sealing plate 61, clip 62, auger bit 70, protrusion 71, ring-shaped folding sleeve 80.

[0020] Such as figure 1 As shown, the drilling equipment for mechanical accessories includes a frame 10, a drilling unit and a clamping unit for clamping a mechanical component 20. The clamping unit is fixed on the frame 10 and located above the drilling unit. The clamping unit is two opposite clamping cylinders 11. When fixing the mechanical accessory 20, the mechanical accessory 20 is placed between the two clamping cylinders 11, and the clamping cylinder 11 is operated to make the piston rod of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com