Planeness detection and correction all-in-one machine and detection and correction method

A flatness detection, all-in-one technology, used in measuring devices, instruments, optical devices, etc., can solve the problems of unqualified product correction, high manual detection cost, low accuracy, etc., to improve production efficiency, avoid surface Scratch, reduce scrap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

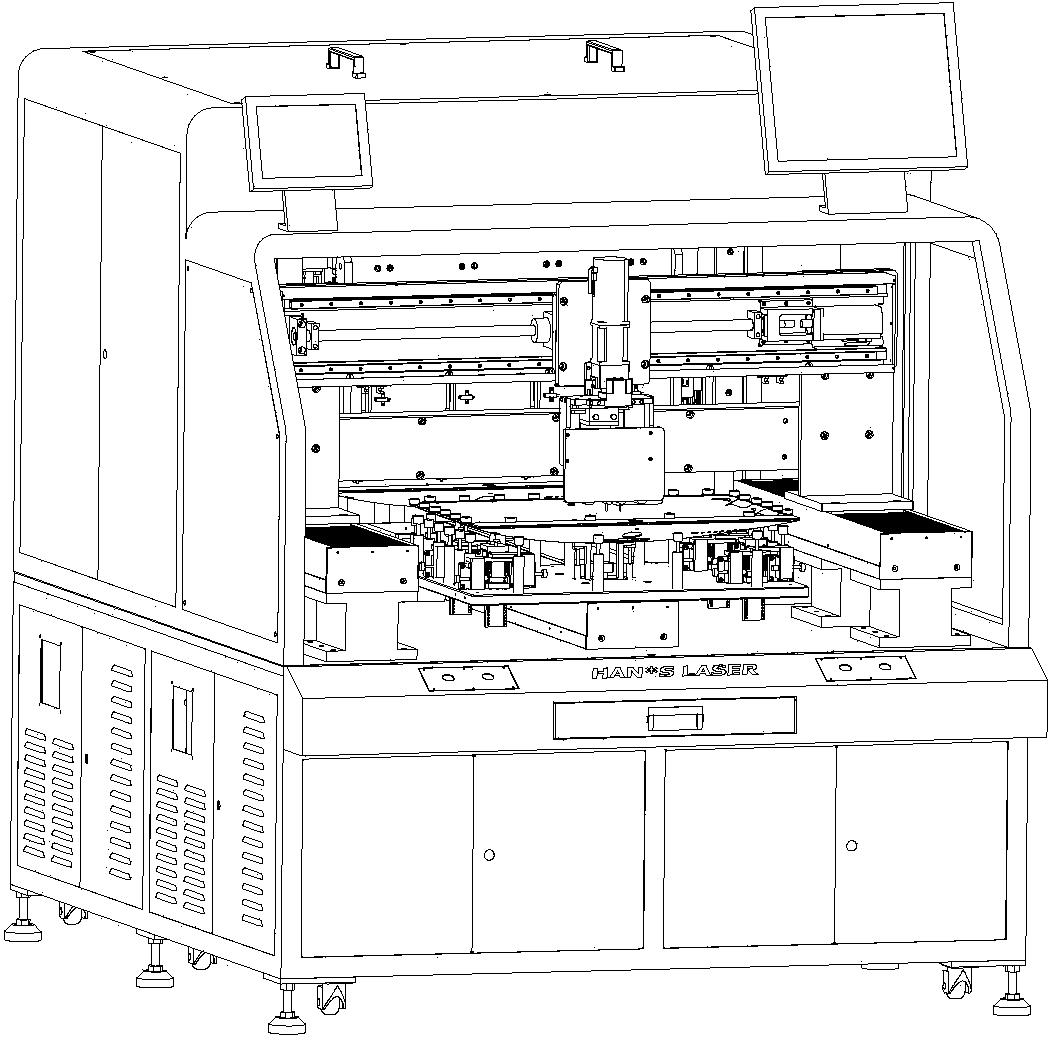

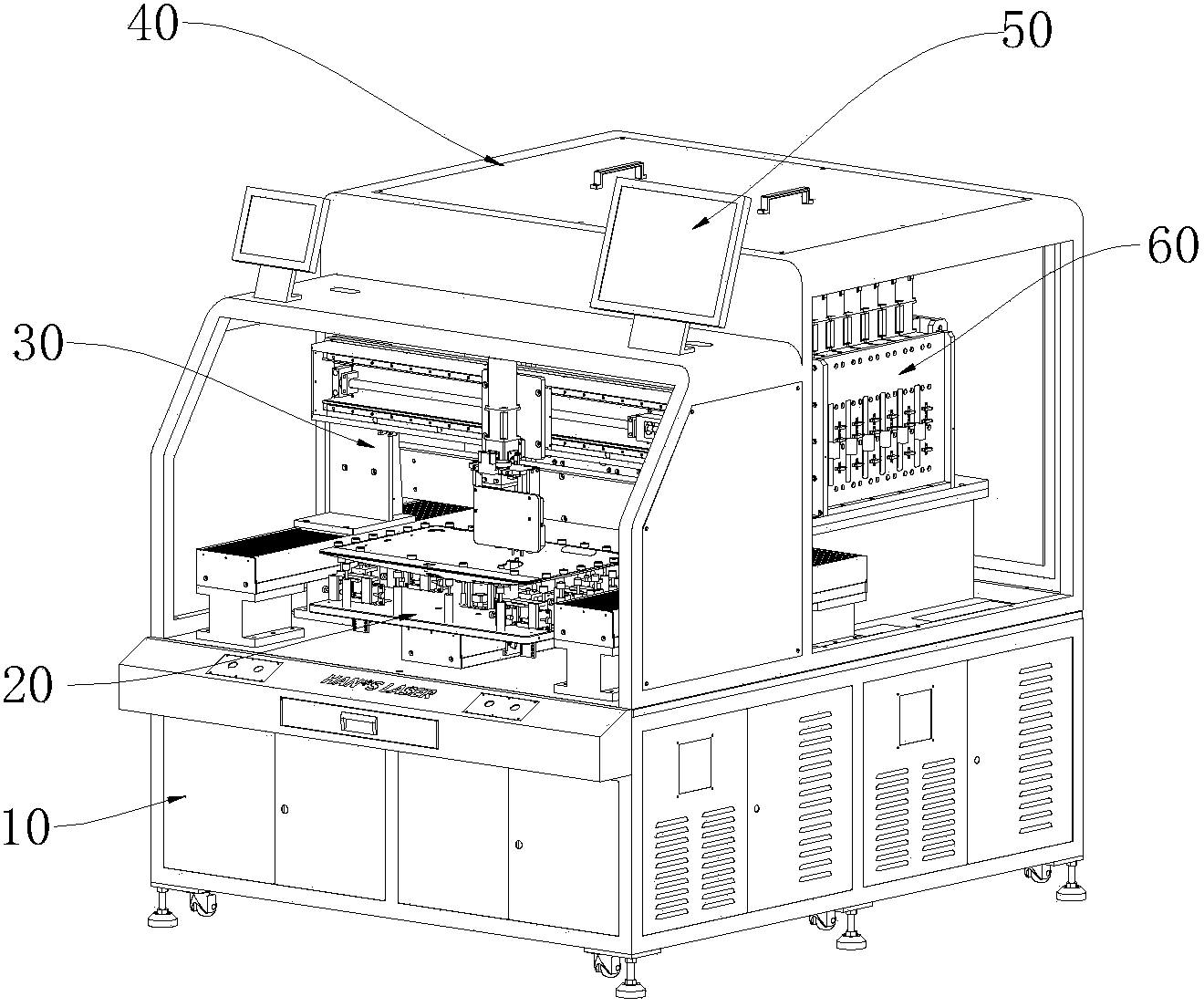

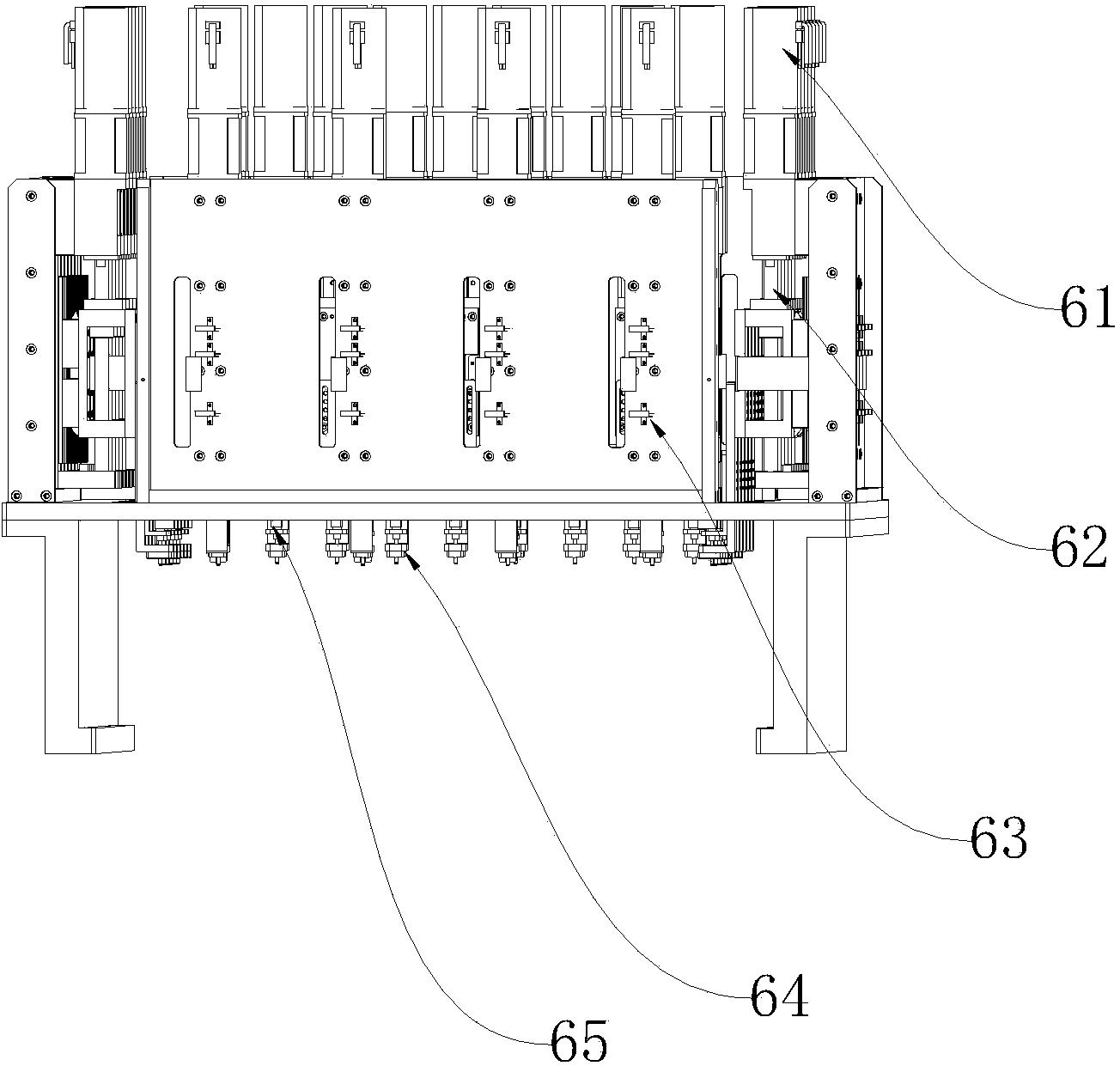

[0029] see figure 1 , figure 2 As shown, the embodiment of the present invention provides a flatness detection and correction integrated machine, including a cabinet assembly 10, a clamp assembly 20 for clamping a modification to be inspected, a control assembly 50 for controlling inspection and correction, and a detection assembly 30. Correction assembly 60 and upper cover assembly 40 . The detection component 30 and correction component 60 are connected with the control component 50 for information exchange to realize the detection and correction of flatness. The detection assembly 30 includes a gantry assembly and a laser displacement sensor 34 for moving in X, Y, and Z axes.

[0030] Such as figure 1 , 2 or 4, the cabinet assembly 10 according to the embodiment of the present invention includes casters 11, foot cups 12, rear outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com