Machining process of NPR steel bar wire rod

A processing technology and steel bar technology, applied in the field of NPR steel bar round processing technology, can solve the problems of not meeting the national green environmental protection requirements, time-consuming and labor-consuming, and inability to complete online digital production, so as to meet the green environmental protection requirements and avoid surface scratch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

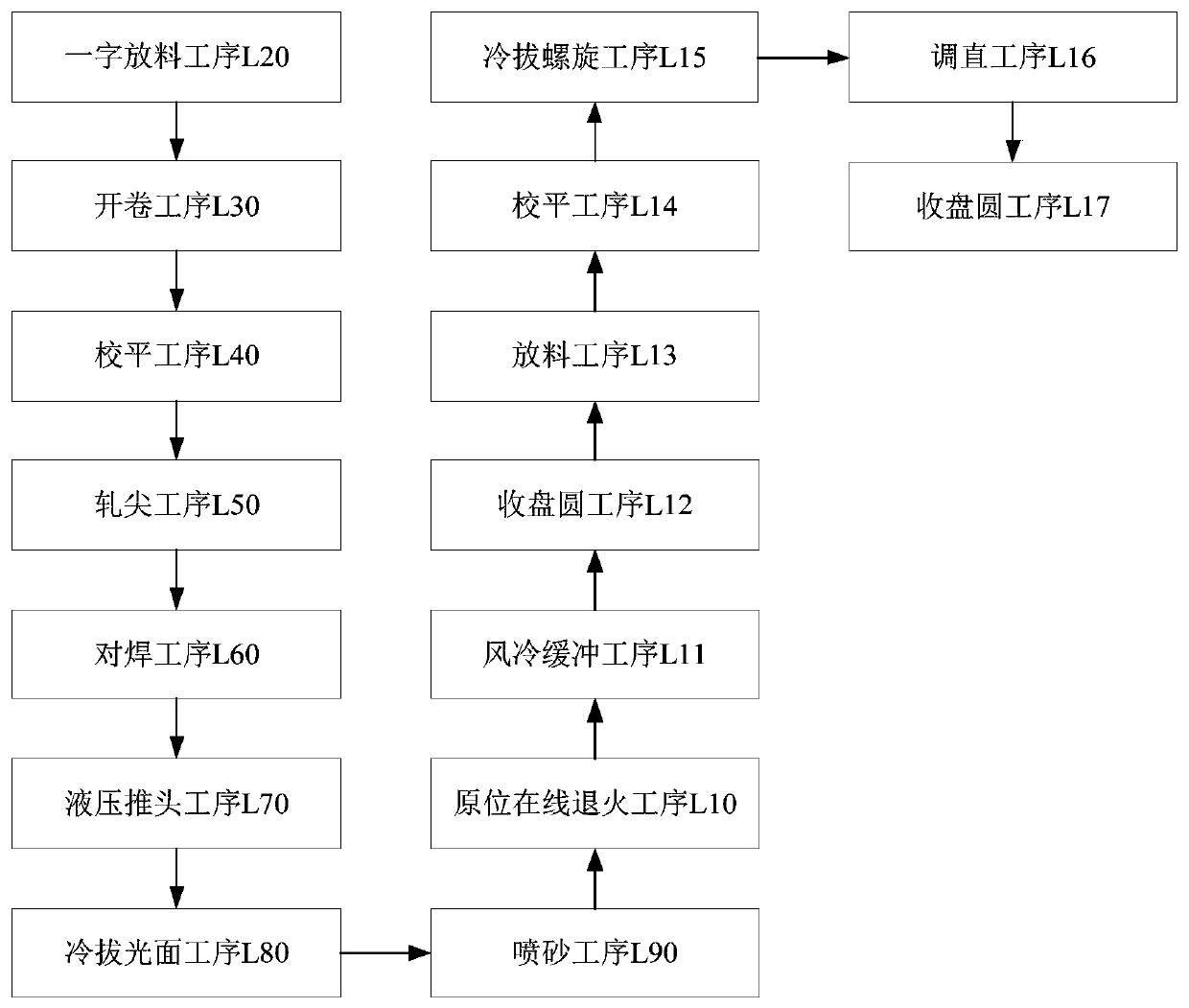

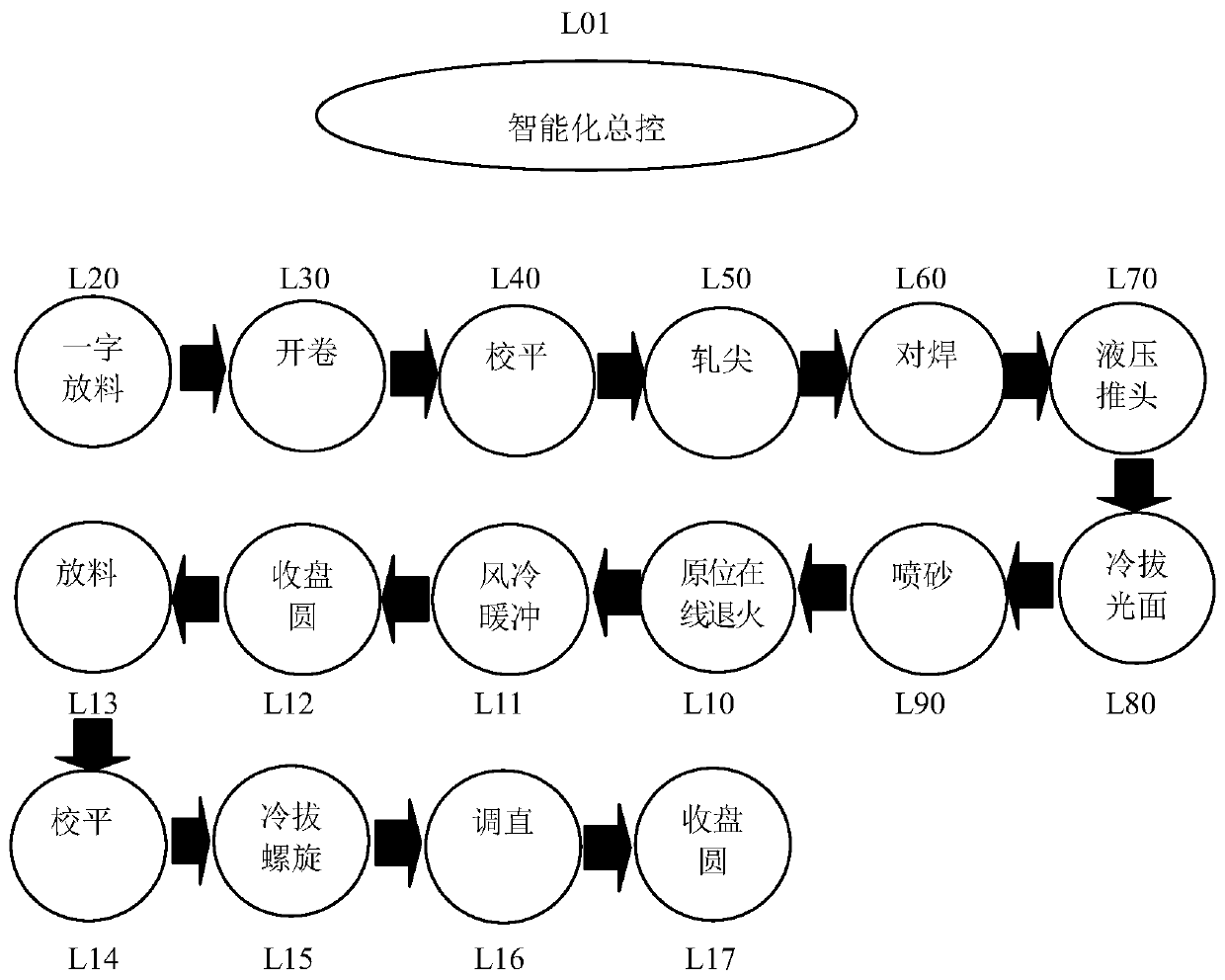

[0024] see figure 1 As shown, according to the embodiments of the present invention, a kind of processing technology of NPR steel bar circle is provided, is processed by fully automatic intelligent NPR cold-rolled (cold drawn) steel bar circle production line, and described NPR steel bar is cold-worked state, so The yield strength of the NPR steel bar is 800MPa-950MPa, the tensile strength is 900MPa-1100MPa, and the maximum force elongation is ≥20%; the steps of the processing technology include:

[0025] Intelligent general control process L10: The intelligent general control system is connected to a remote computer server through an optical fiber network cable, and the remote one-key automatic start and stop can be realized through the server. Check the running status and production...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com