High-haze colored ultra-thin high-frequency cover film and preparation method thereof

一种高雾度、覆盖膜的技术,应用在化学仪器和方法、印刷电路制造、层压等方向,能够解决不易做到等问题,达到防止表面刮伤、不易腐蚀、提高硬度及机械强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

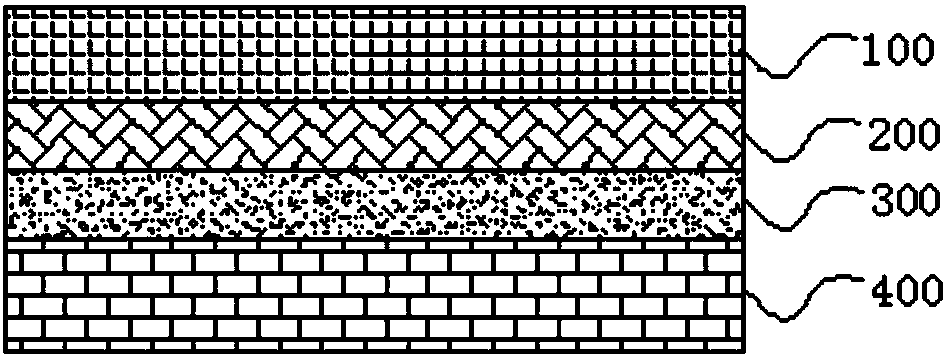

[0064] Embodiment 1: A kind of high-haze colored ultra-thin high-frequency cover film, such as figure 1 Shown, comprise colored ink layer 200 and high-frequency adhesive layer 300, described colored ink layer 200 is positioned at the top of described high-frequency adhesive layer 300, and described colored ink layer is provided with at least one layer;

[0065] The hardness of the colored ink layer is HB-5H;

[0066] The glossiness of the colored ink layer is 0-60% (60°);

[0067] The roughness of the colored ink layer is 50-1000nm;

[0068] The thickness of the colored ink layer is 1-10 μm, and the thickness of the high-frequency adhesive layer is 3-25 μm.

[0069] In this embodiment, the colored ink layer has a single layer, and the sum of the thicknesses of the colored ink layer 200 and the high frequency adhesive layer 300 is 4-35 μm.

[0070] Preferably, the hardness of the colored ink layer 200 is 2H-5H.

[0071] Preferably, the thickness of the colored ink layer 200...

Embodiment 2

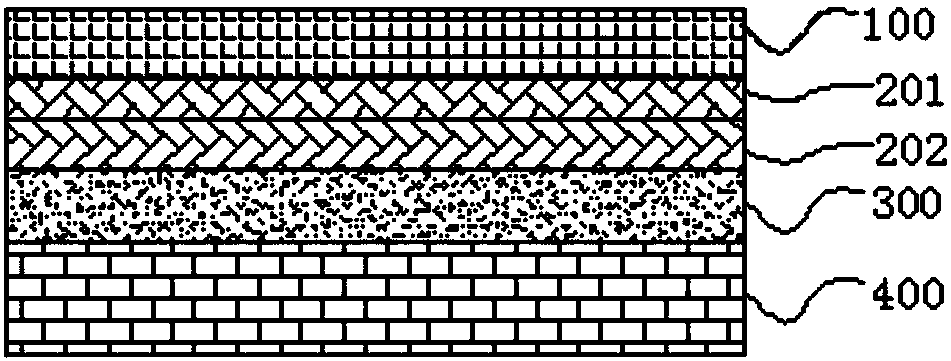

[0087] Embodiment 2: as figure 2 As shown, the others are the same as in Example 1, except that the colored ink layer is provided with two layers, which are respectively the first colored ink layer 201 and the second colored ink layer 202, and the first colored ink layer 201 Located on the upper surface of the second colored ink layer 202, the second colored ink layer 202 is located on the upper surface of the high frequency adhesive layer 300;

[0088] The thicknesses of the first colored ink layer 201 and the second colored ink layer 202 are both 2-3 μm.

[0089]The resin material in the auxiliary adhesive layer is epoxy resin, acrylic resin, urethane resin, silicone rubber resin, parylene resin, bismaleimide resin, polyamide amide At least one of imine and the polyimide-based resin.

Embodiment 3

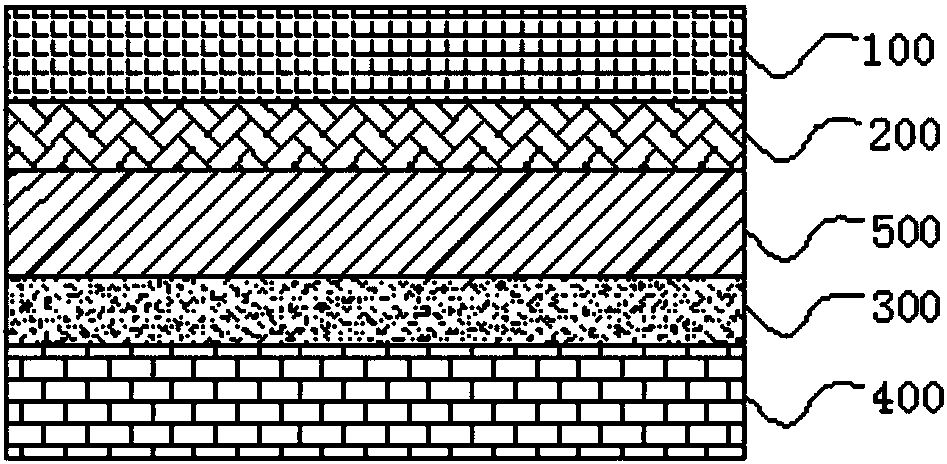

[0090] Embodiment 3: as image 3 As shown, the others are the same as in Embodiment 1, except that: the colored ultra-thin high-frequency cover film also includes an auxiliary adhesive layer 500, and the auxiliary adhesive layer 500 is located between the colored ink layer 200 and the high-frequency adhesive layer. between the agent layers 300, and the thickness of the auxiliary adhesive layer 500 is 3-25 μm.

[0091] The present invention also provides a kind of preparation method of the colored ultra-thin high-frequency covering film of described high haze, and described preparation method is a kind of in following method:

[0092] Method one (applicable to embodiment 1): proceed as follows:

[0093] Step 1. Coating colored ink raw materials on the lower surface of the upper release layer, curing at a low temperature of 50-180°C to form a colored ink layer;

[0094] Step 2, forming the high-frequency adhesive layer on the lower surface of the colored ink layer by coating m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com