Glass alignment positioning system for the ultra-thin glass on-line automatic sheet-fetching

An ultra-thin glass, centering and positioning technology, which is applied in the directions of positioning objects, thin material processing, pile separation, etc., can solve the problem of unusable glass original sheets, avoid surface scratches, improve yield and packaging quality, accurate The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

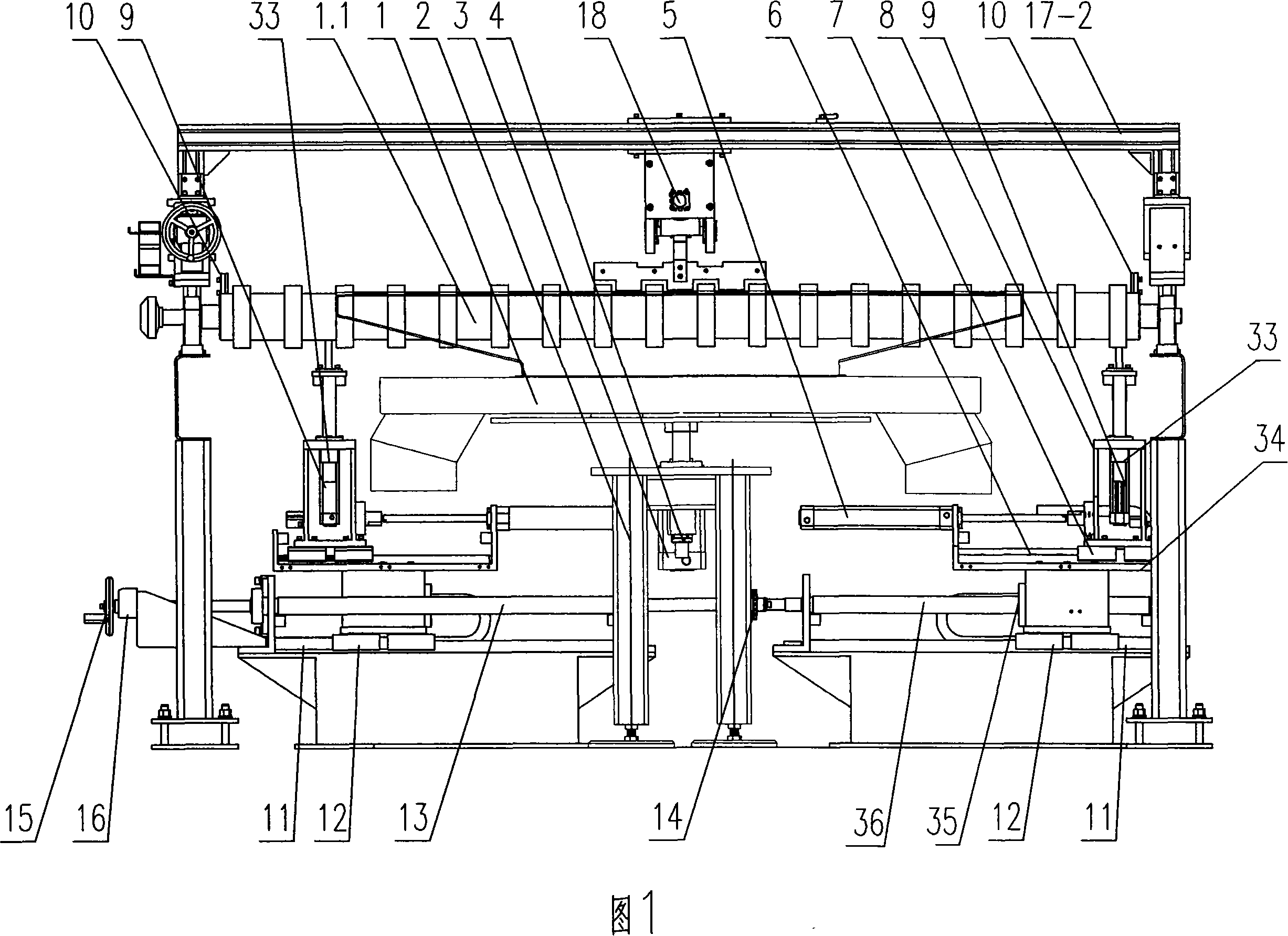

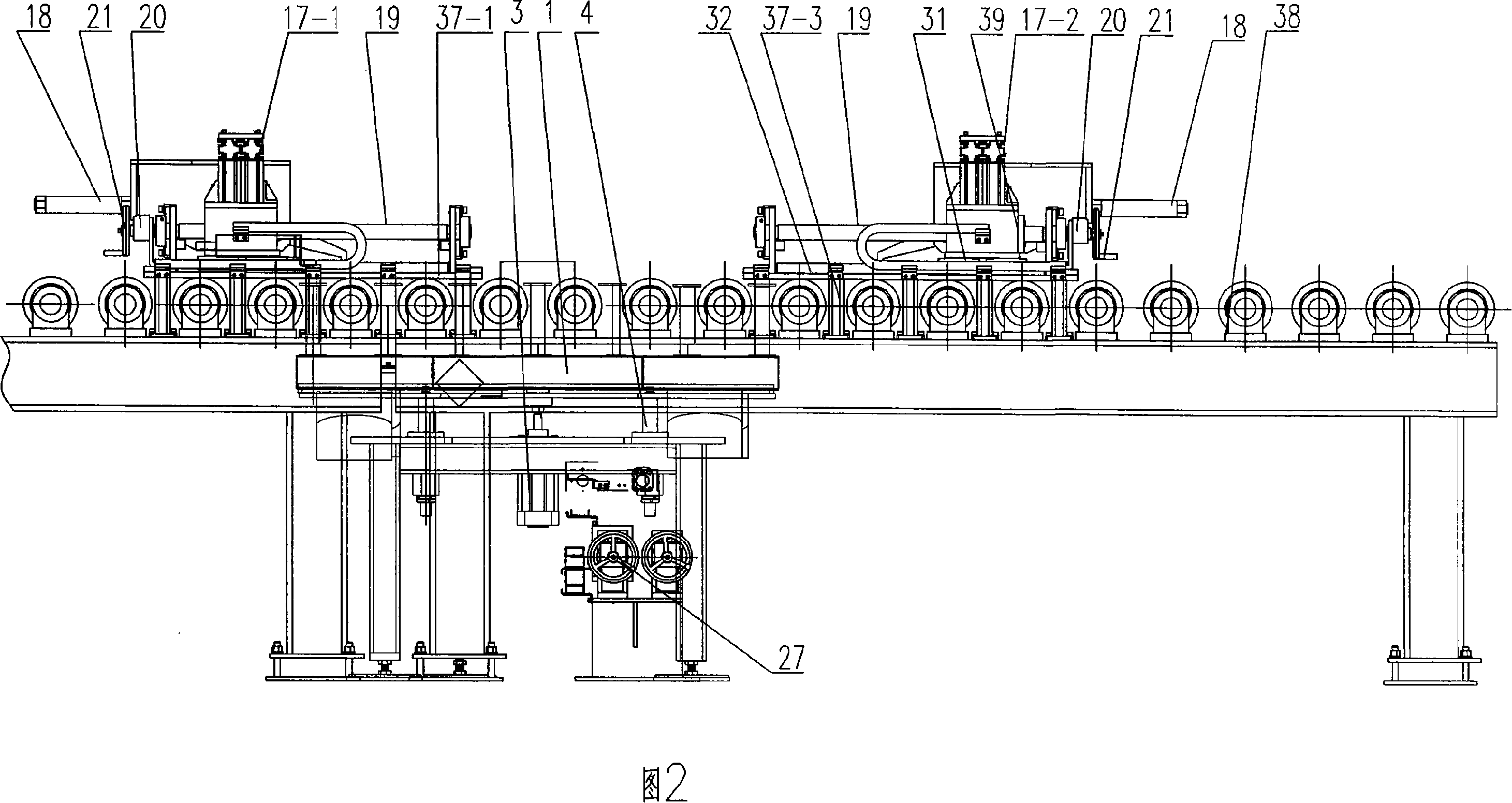

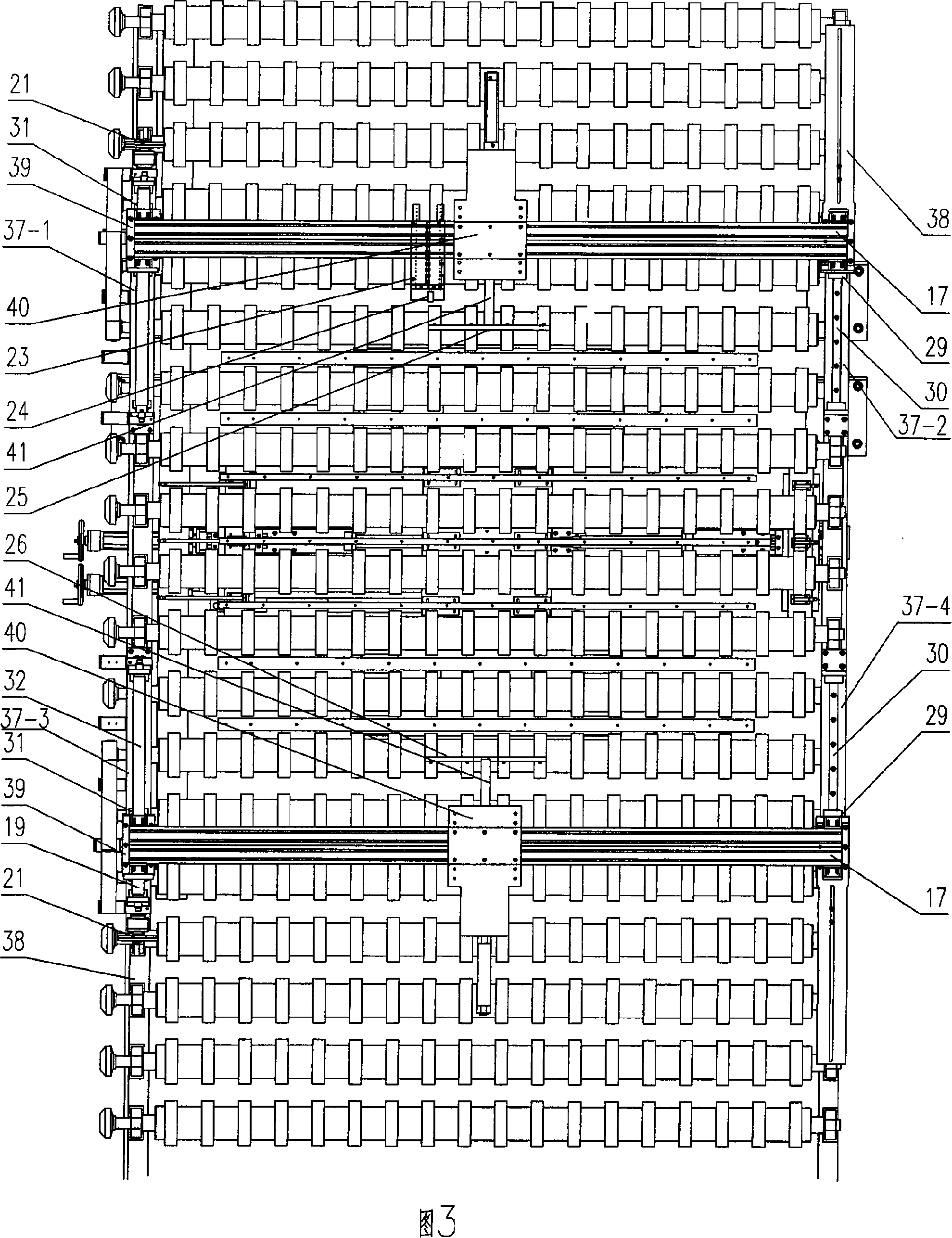

[0016] Specific embodiments of the present invention are described with reference to the accompanying drawings.

[0017] As shown in accompanying drawings 1, 2, 3, and 4: the present invention includes a front and rear centering device for front and rear positioning of glass, a left and right centering device for left and right positioning of glass, and an air flotation device for a wind collecting box. The front and rear centering devices are arranged on On the upper part of the glass conveying line 38, the air flotation device of the wind collecting box is arranged under the glass conveying branch line 38 between the front and rear centering devices, and the left and right centering devices are arranged on both sides of the air flotation device of the wind collecting box. The bellows blow air, and at the same time the bellows move upwards, and the glass is blown up. The front and rear centering devices clamp the glass front and back, and the left and right centering devices m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com