Gas supply unit, substrate processing apparatus, and supply gas setting method

a substrate processing and gas supply technology, applied in water supply installation, process and machine control, instruments, etc., can solve the problems of complicated piping structure of gas supply system, increasing the cost of apparatus control system, etc., to achieve simple piping configuration and reduce the cost of controlling flow rate , the effect of reducing the spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

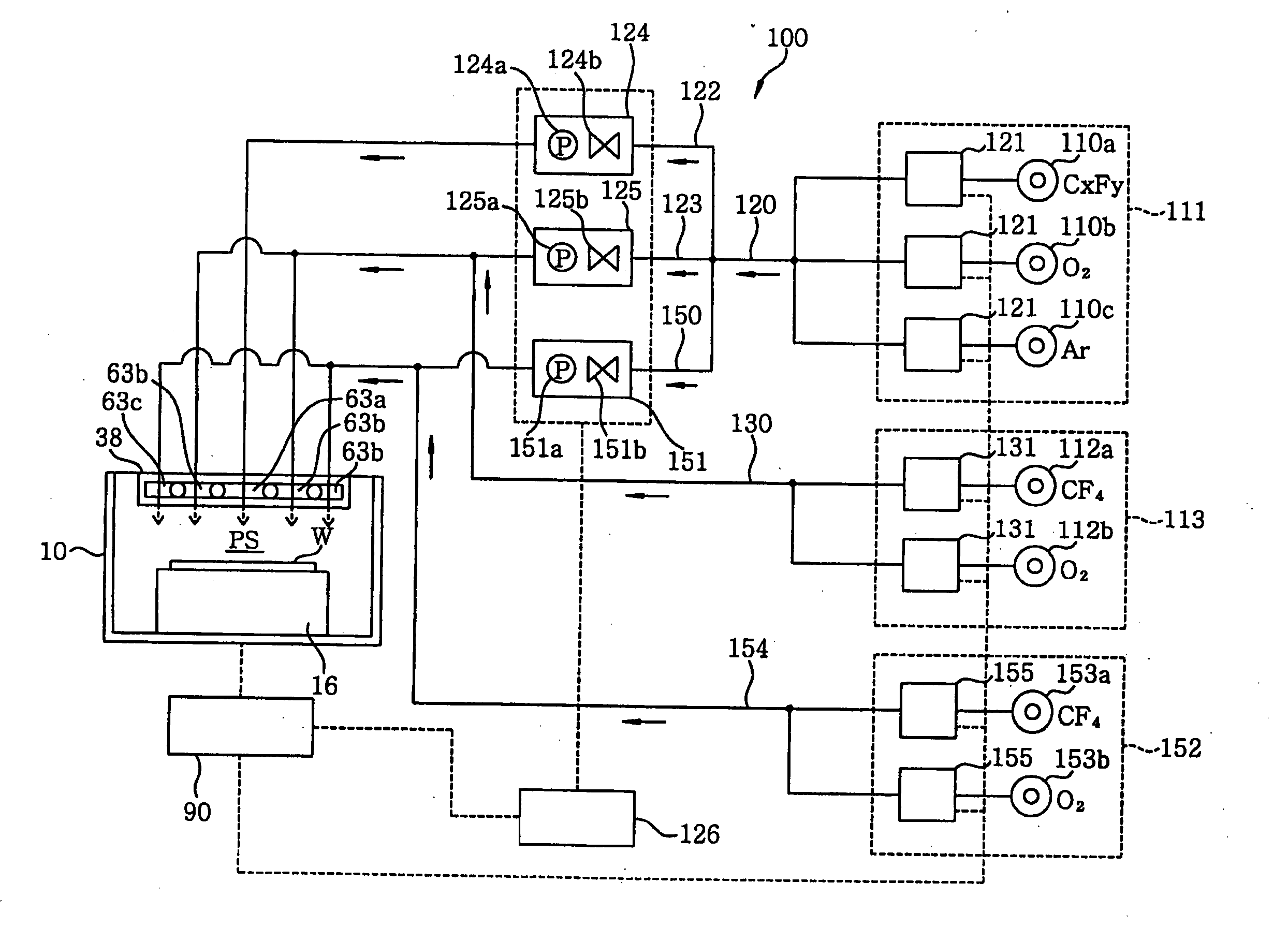

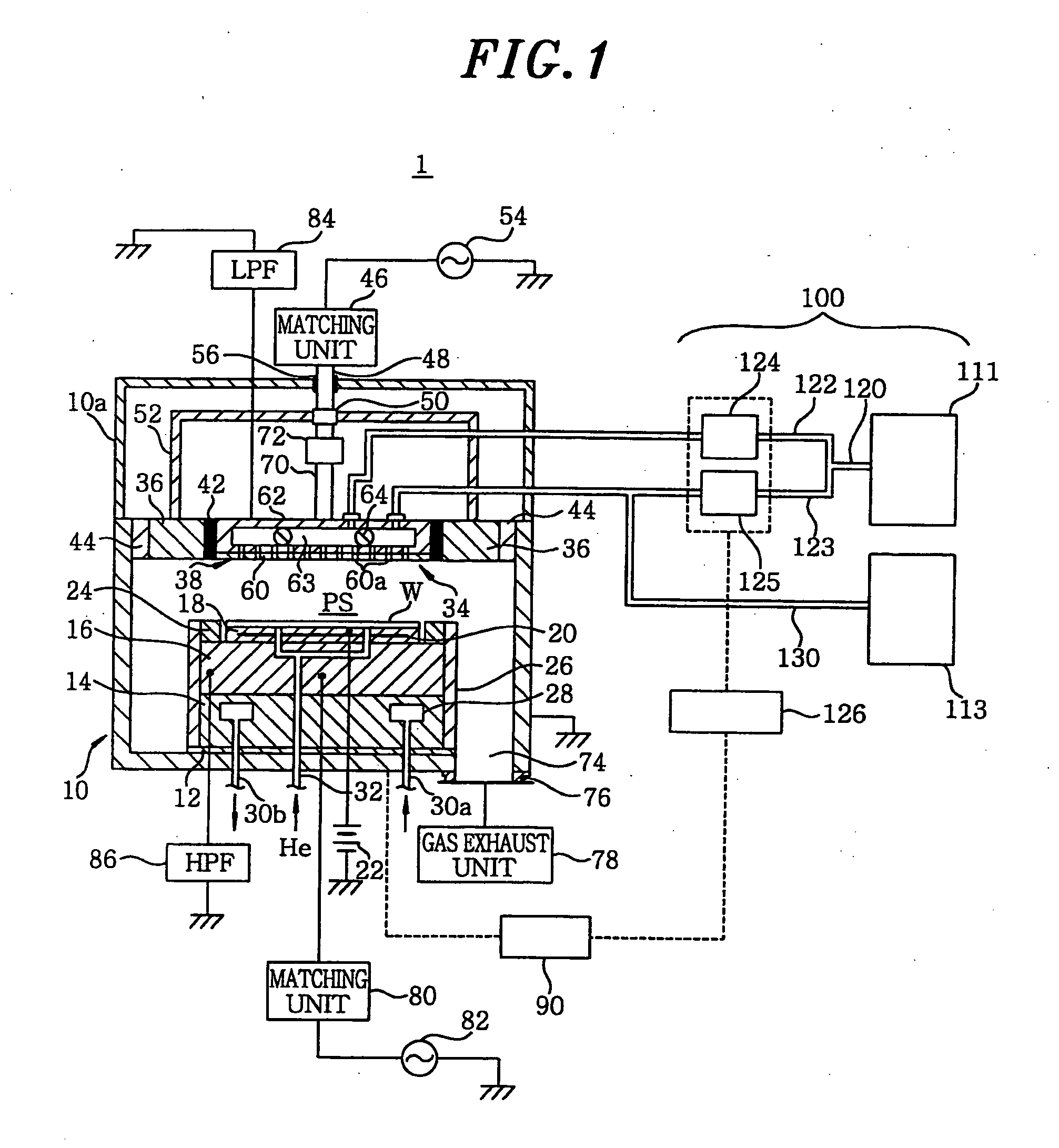

[0023] Hereinafter, a preferred embodiment of the present invention will be described. FIG. 1 is a longitudinal sectional view showing a schematic configuration of a plasma etching apparatus 1 serving as a substrate processing apparatus including a gas supply unit in accordance with the preferred embodiment of the present invention.

[0024] The plasma etching apparatus 1 is a capacitively coupled plasma etching apparatus having a parallel plate type electrode structure. The plasma etching apparatus 1 includes an approximately cylindrical processing chamber 10 that is grounded. The processing chamber 10 is formed of, e.g., aluminum alloy and the inner wall surface thereof is covered by an alumina film or an yttrium oxide film.

[0025] A cylindrical susceptor supporting table 14 is disposed in a central bottom portion of the processing chamber 10 via an insulating plate 12. A susceptor 16, serving as a mounting table, for mounting thereon a wafer W, i.e., a substrate, is disposed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com