Heat exchanging fluid return manifold for a liquid cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Many of the fastening, connection, manufacturing and other means and components utilized in this invention are widely known and used in the field of the invention are described, and their exact nature or type is not necessary for a person of ordinary skill in the art or science to understand the invention; therefore they will not be discussed in detail.

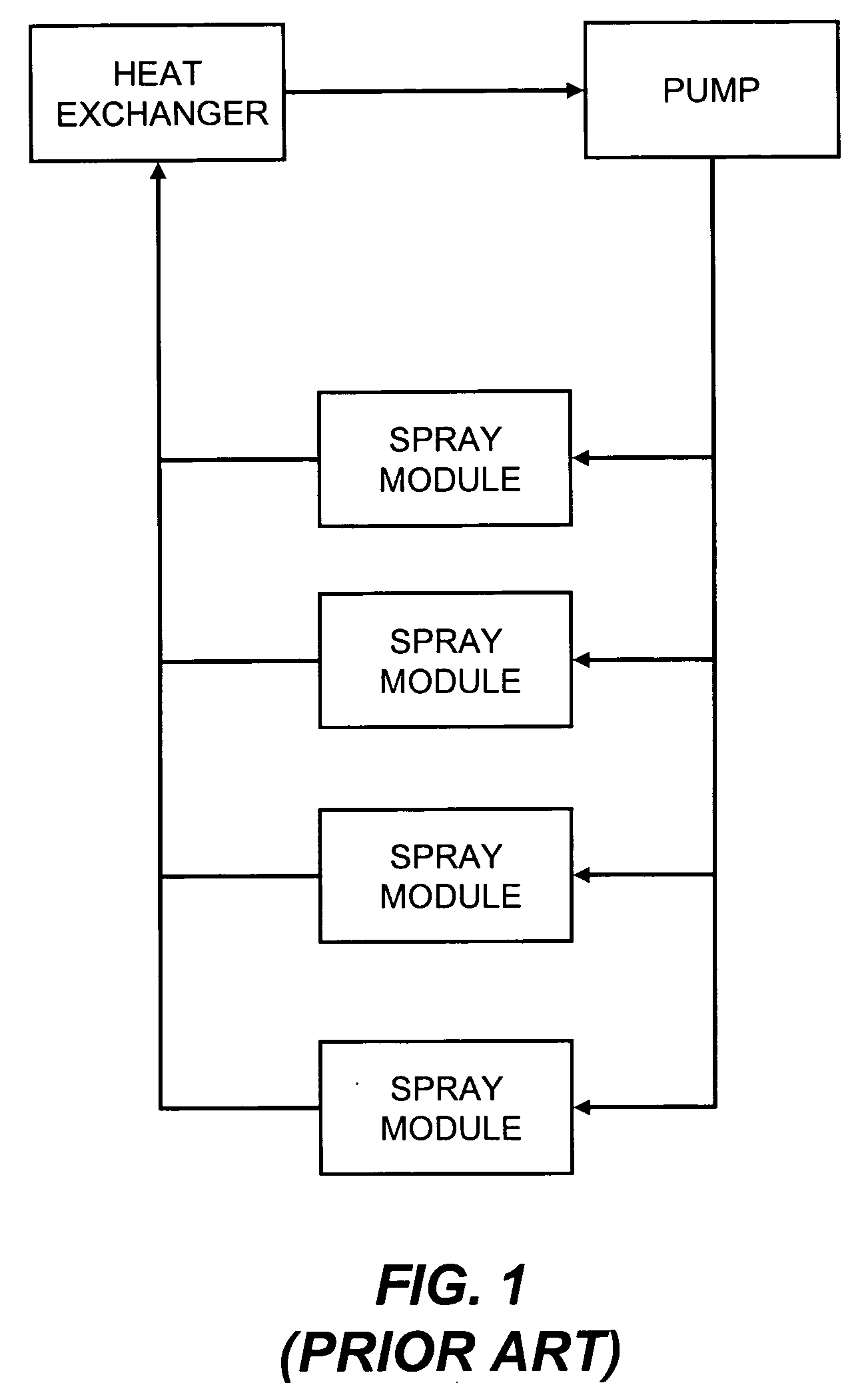

[0033]Applicant hereby incorporates by reference U.S. Pat. No. 5,220,804 for a high heat flux evaporative cooling system. Although spray cooling is herein described as the preferred method of two-phase cooling, the present invention is not limited to such a system. Spray cooling is only discussed in detail to provide a known preferred embodiment. In addition to two-phase spray cooling, the present invention is applicable to, but not limited to, single-phase cooling and refrigeration systems.

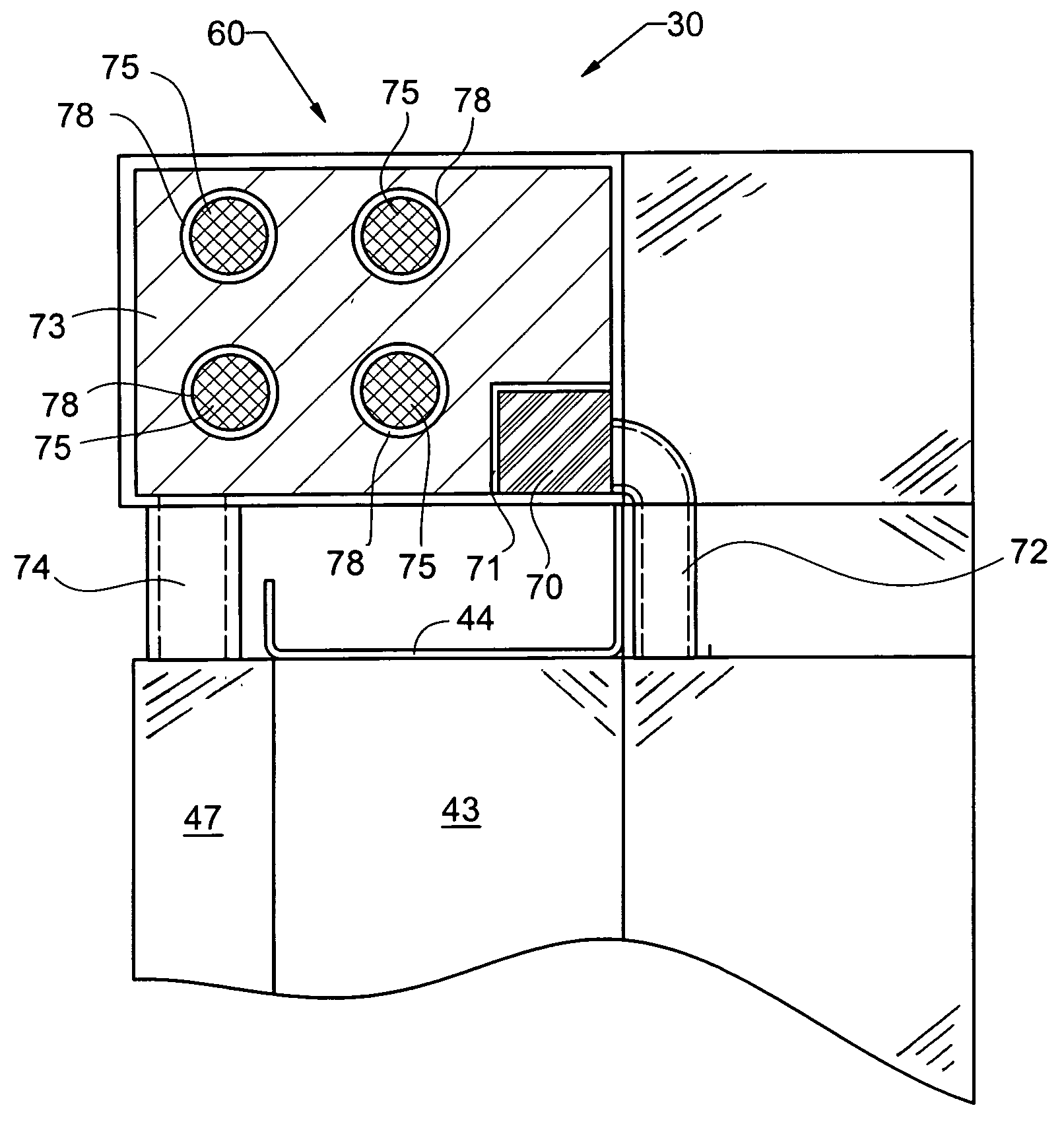

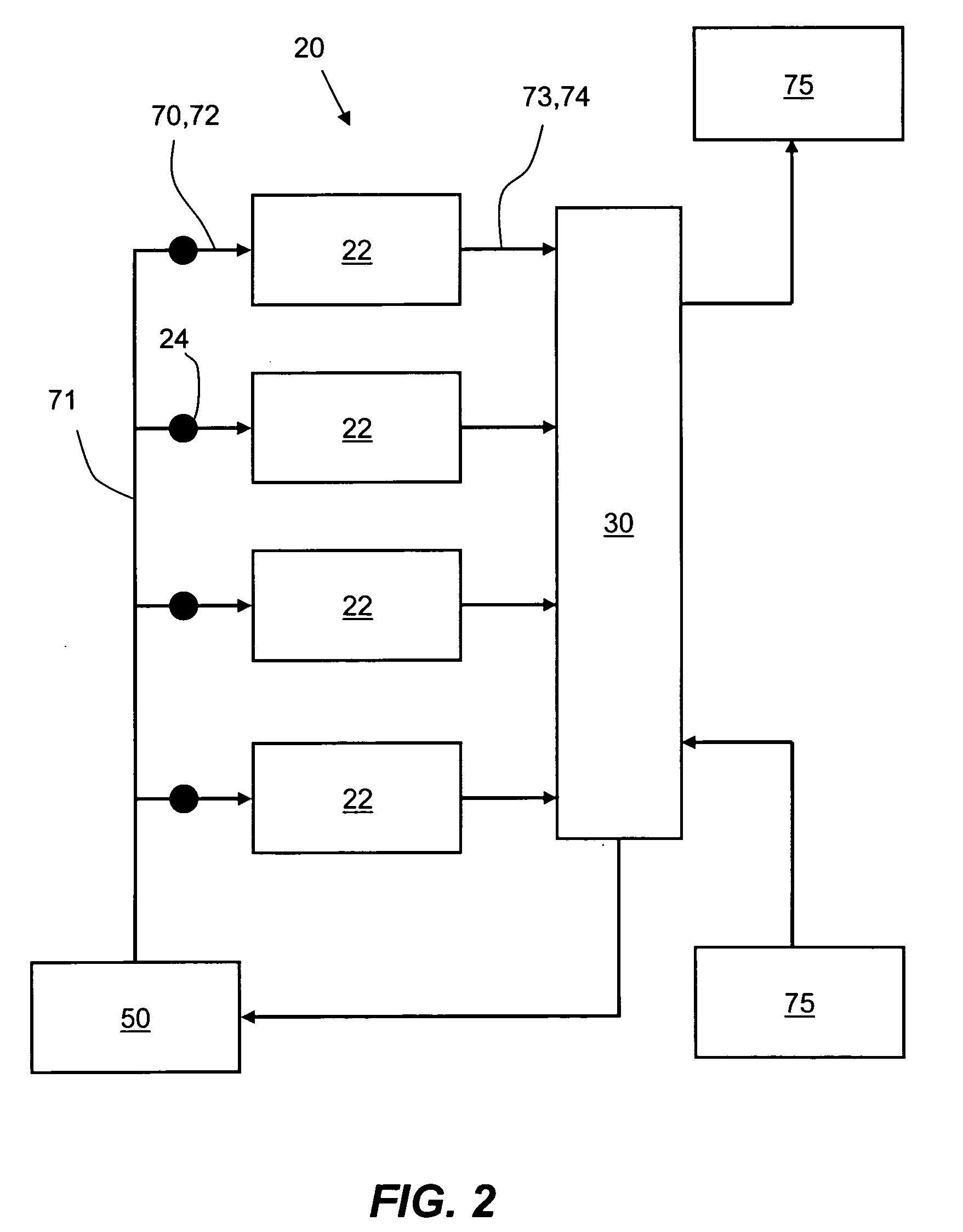

[0034]FIG. 2 shows a liquid cooling system 20, according to the present invention. A plurality of thermal management units 22, such as descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com