A manufacturing system for large-diameter steel-plastic winding pipe flanges

A manufacturing system and winding pipe technology, which is applied in the system field of manufacturing large-diameter steel-plastic wound pipe flanges, can solve the problem of inability to manufacture large-diameter steel-plastic wound pipe flanges, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

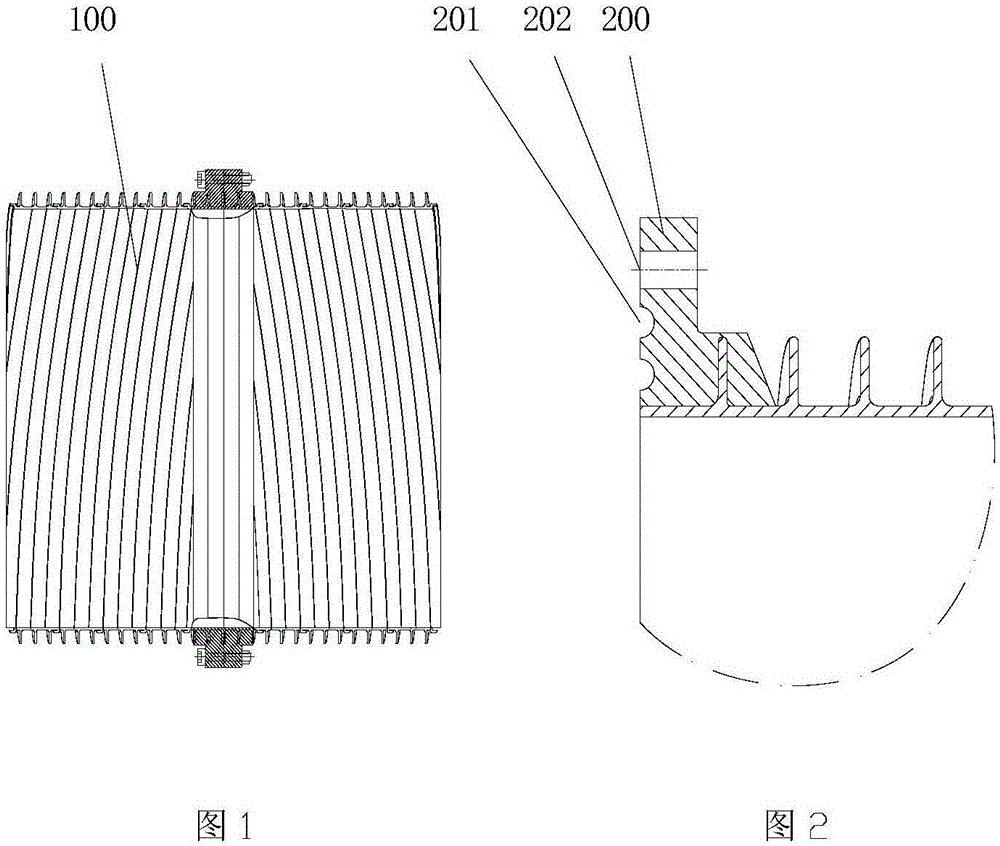

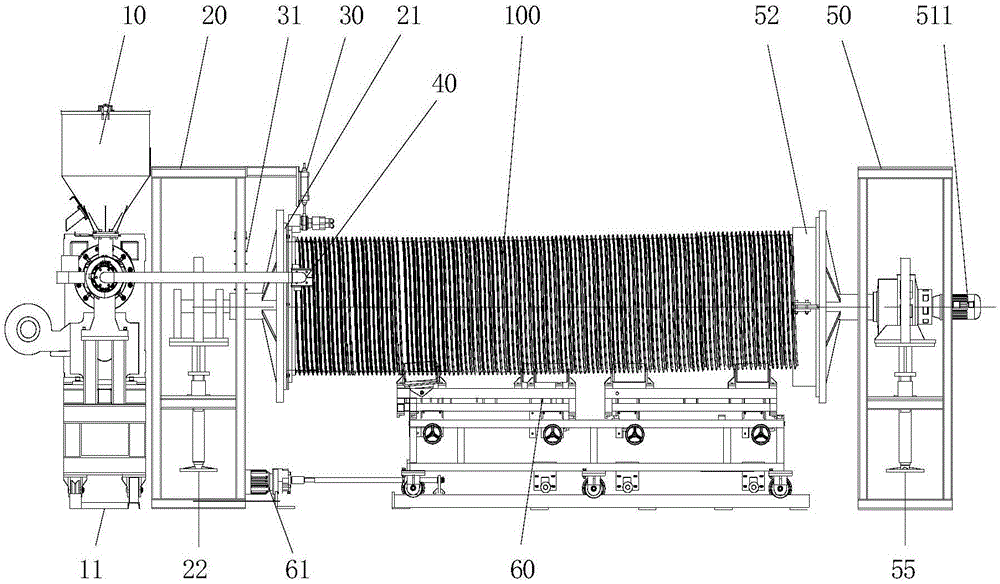

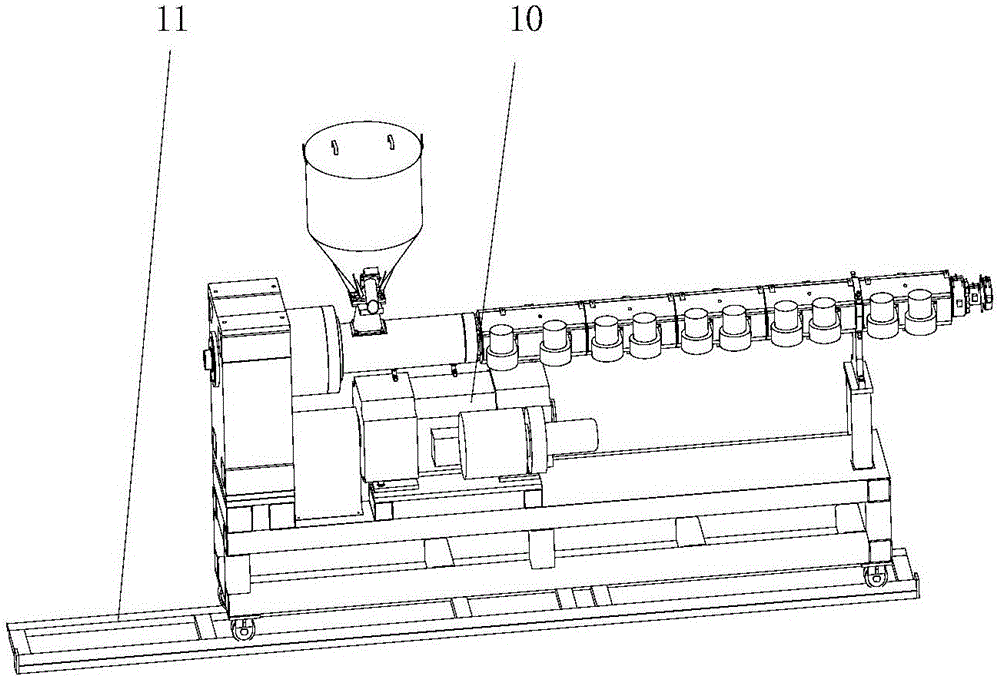

[0040] Such as Figure 3 to Figure 12 As shown, the manufacturing system of the large-diameter steel-plastic winding pipe flange of the present invention includes plasticizing extrusion equipment, a rotating power mechanism 50, a positioning mechanism 20, a pressure roller mechanism 30, a cooling device output pipe 33 and a bracket 60.

[0041] The plasticizing extrusion equipment includes an extruder 10 and a die 40 connected to the extrusion end of the extruder 10 . The extruder 10 plasticizes and melts the solid plastic particles, and extrudes them through the die 40 to form a melt sheet with a certain width and thickness.

[0042] Die 40 is known in the art. Such as Figure 5 to Figure 7 As shown, the mold 40 includes an upper mold 41 and a lower mold 42 that cooperate with each other. The upper mold 41 includes a mold cavity 411 , and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com