Large-size no-lining composite material storage tank mold and using method and application

A composite material and large-size technology, which is applied in the field of large-size non-lined composite material storage tanks, can solve the problems of difficult preparation, heavy weight, and high price, and achieve the effect of improving dimensional accuracy and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

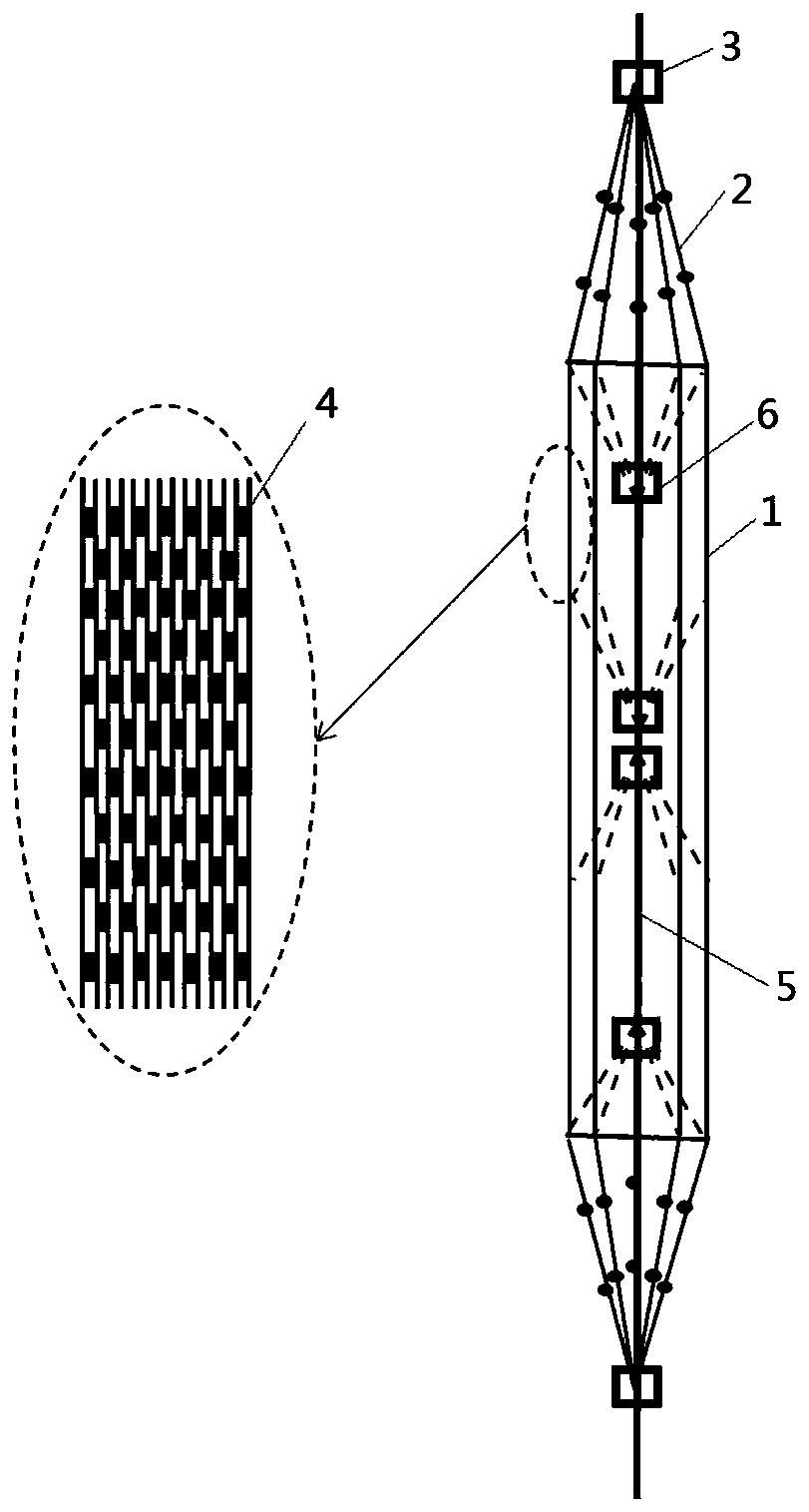

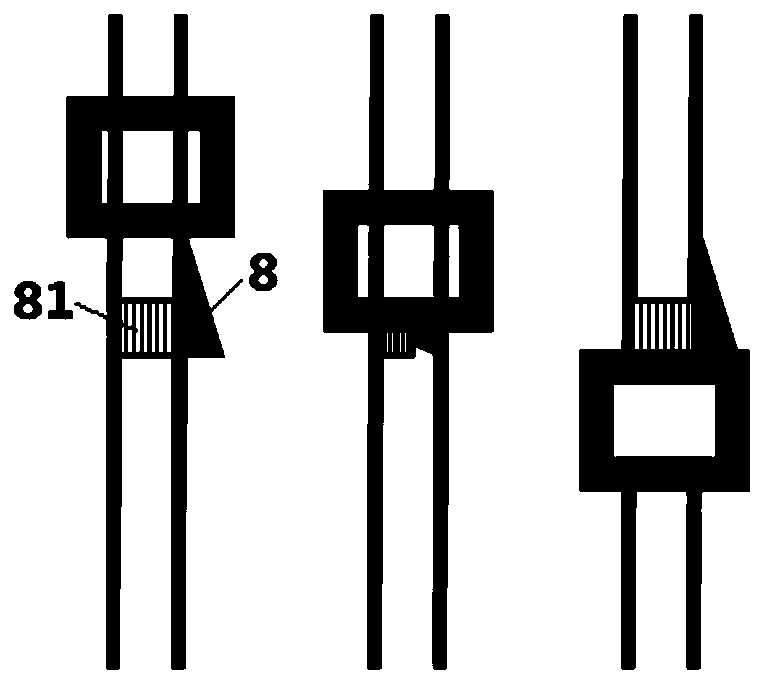

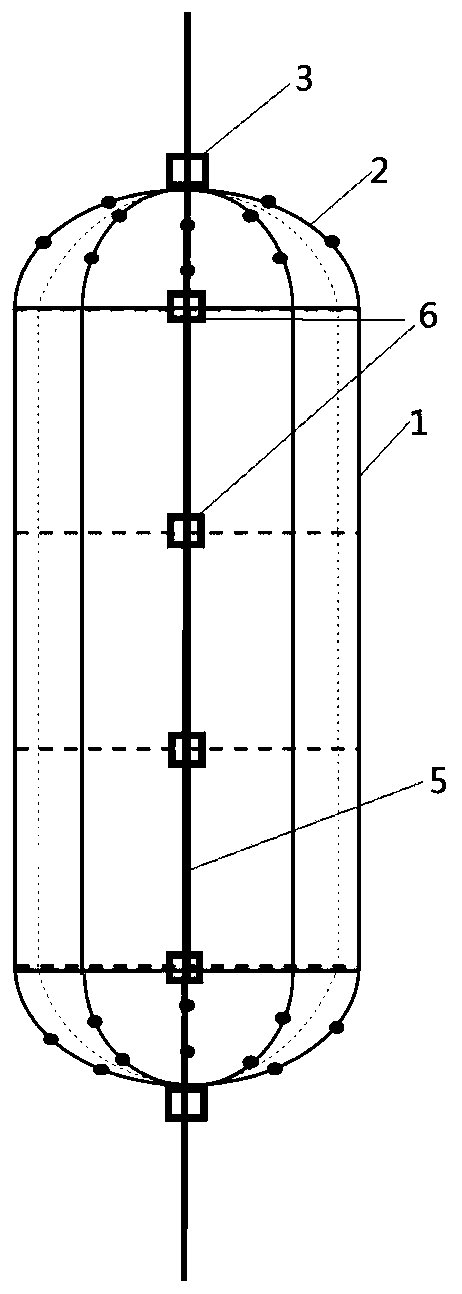

[0033] A mold for a large-size non-lined composite material storage tank, including a shell frame 1 and a head frame 2 connected to the two bottom surfaces of the shell frame 1, the shell frame 1 is covered with a honeycomb structure mesh 4, and the detachable cylindrical skeleton structure of the honeycomb structure mesh 4, the head skeleton 2 is a conical skeleton structure with the honeycomb structure mesh 4 covered on the side, and the honeycomb structure mesh 4 is detachable. The cone top of the head frame 2 is provided with a head shaft sleeve 3, the cone bottom of the head frame 2 is connected with the shell frame 1, and the central axis of the shell frame 1 and the head frame 2 is provided with a main shaft 5, and the main shaft 5 Through the head bushing 3, there are several barrel bushings 6 on the main shaft 5 located inside the barrel frame 1. The barrel bushings 6 and the side of the barrel frame 1 are connected by several brackets 7, and the brackets 7 are in the ...

Embodiment 2

[0040] The method for using the mold of a large-size non-lined composite material storage tank includes the following steps:

[0041]1) Connect all parts of the device through bolts, and apply force in opposite directions to the two head bushings, so that the head frame and the body frame are stretched at the same time, and the honeycomb structure of the honeycomb structure mesh is pulled apart, so that the seal The head bushing and barrel bushing are held in place by a spring locking device, at which point the device assumes the shape of a capsule;

[0042] 2) Paste a release cloth on the surface of the unfolded honeycomb structure mesh;

[0043] 3) Wrap fibers or lay prepreg tape on the surface of the mold with release cloth, and put it into the curing furnace together with the mold to heat and cure after molding;

[0044] 4) After the curing is completed, the spring locking device is opened, and the force in the opposite direction is applied to the two head bushings, and t...

Embodiment 3

[0047] For an unlined composite storage tank with a cylinder body length of 10m, a diameter of 4m, a hemispherical head, and a pole hole diameter of 1m:

[0048] 1. Mold assembly:

[0049] 1) The outer frame of the barrel frame 1 is composed of eight 6-meter-long steel bars. The middle position of each steel bar is evenly distributed with two connecting ears by welding, and the connecting frames are welded at both ends. A total of 2 sets are installed inside the barrel frame 1. Each set of supports 7 is composed of eight 2-meter-long thin steel bars, and each thin steel bar is welded with a connecting frame at both ends, and one end of the bolt is connected to the shaft sleeve 6 of the cylinder, and the other end is connected to the cylinder. On the frame of the outer frame of the body frame 1, the steel bars of the bracket can rotate freely at the bolt connection;

[0050] 2) There are two head skeletons 2 in the mold, and the outer outline skeleton of each head skeleton 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com