Polymer microneedle preparation system and method

A preparation system and polymer technology, applied in the field of new micro-precision molding processing of polymer materials, can solve the problems of high manufacturing cost, difficult batch preparation, large skin irritation, etc., and achieve mild manufacturing conditions, expand the scope of use, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] (1) Preparation of hyaluronic acid solution

[0062] The hyaluronic acid powder was added to the aqueous solution containing 1% sodium chloride under stirring, and the aqueous solution of hyaluronic acid (molecular weight 1000 000) was prepared by dissolving, stirring for 2 hours to prepare a concentrated solution of 10% by mass, and ultrasonically oscillating to remove the solution residual air bubbles.

[0063] (2) Preparation of hyaluronic acid microneedles

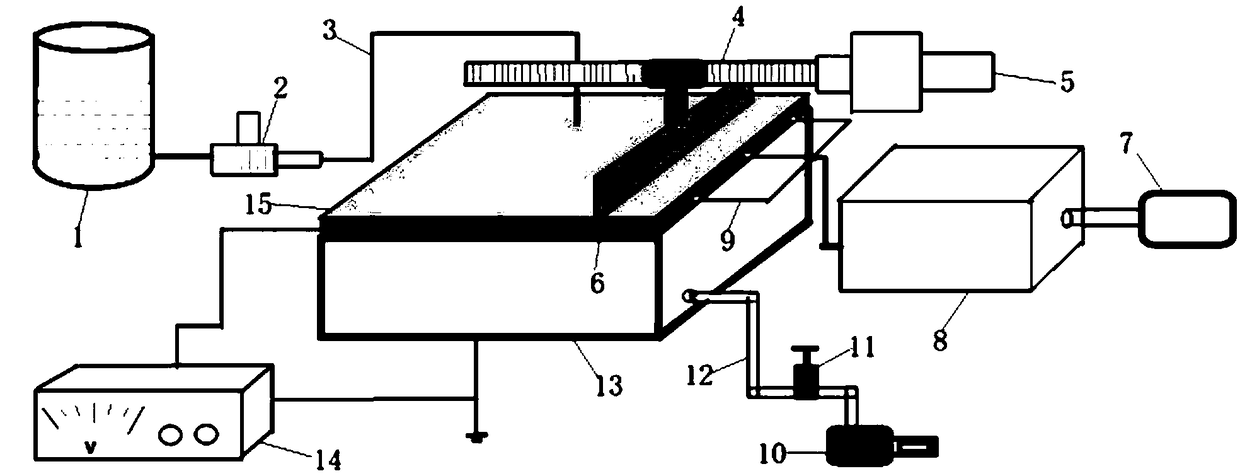

[0064] i. Add the prepared hyaluronic acid solution to the polymer solution storage tank of the polymer microneedle preparation system, turn on the metering delivery pump, and pump it into the microneedle plate mold.

[0065] ii. Turn on the scraper and adjust the height of the scraper, so that the scraper is driven by the motor to scrape the hyaluronic acid solution into a thin layer and evenly distribute it on the surface of the flat microneedle mold.

[0066] iii. Turn on the power of the high-voltage elect...

Embodiment 2

[0071] (1) Preparation of collagen solution

[0072] The collagen powder was added to an aqueous solution containing 0.5% acetic acid under stirring, and an aqueous solution of collagen (molecular weight 100 000) was prepared by dissolving, stirring for 2 hours to prepare a concentrated solution of 20% by mass, and ultrasonically oscillating to remove residual bubbles in the solution.

[0073] (2) Preparation of collagen microneedles

[0074] i. Add the prepared collagen solution into the polymer solution storage tank of the polymer microneedle preparation system, turn on the metering delivery pump, and pump it into the microneedle plate mold.

[0075]ii. Turn on the scraper and adjust the height of the scraper, so that the scraper is driven by the motor to scrape the collagen solution into a thin layer and evenly distribute it on the surface of the flat microneedle mold.

[0076] iii. Turn on the power of the high-voltage electric field generator, adjust the output voltage t...

Embodiment 3

[0081] (1) Preparation of chitosan solution

[0082] Add the chitosan powder to the 0.1% acetic acid aqueous solution under stirring, dissolve and prepare the chitosan (molecular weight 500 000) aqueous solution, stir for 6 hours, make a 15% mass percent concentrated solution, and remove the residual bubbles in the solution by ultrasonic vibration .

[0083] (2) Preparation of Chitosan Microneedles

[0084] i. Add the prepared chitosan solution into the polymer solution storage tank of the polymer microneedle preparation system, turn on the metering delivery pump, and pump it into the microneedle plate mold.

[0085] ii. Turn on the scraper and adjust the height of the scraper, so that the scraper is driven by the motor to scrape the chitosan solution into a thin layer and evenly distribute it on the surface of the flat microneedle mold.

[0086] iii. Turn on the power of the high-voltage electric field generator, adjust the output voltage to 40KV, establish a high-voltage e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com