High-performance seamless flux-cored wire for copper and aluminum containing rare earth elements and manufacturing method of high-performance seamless flux-cored wire

A technology of seamless flux-cored welding wire and rare earth elements, which is used in manufacturing tools, welding equipment, welding media, etc., can solve the problems of capillary fusion of strength welding materials, general performance, and unsatisfactory plasticity, so as to improve plasticity and toughness, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

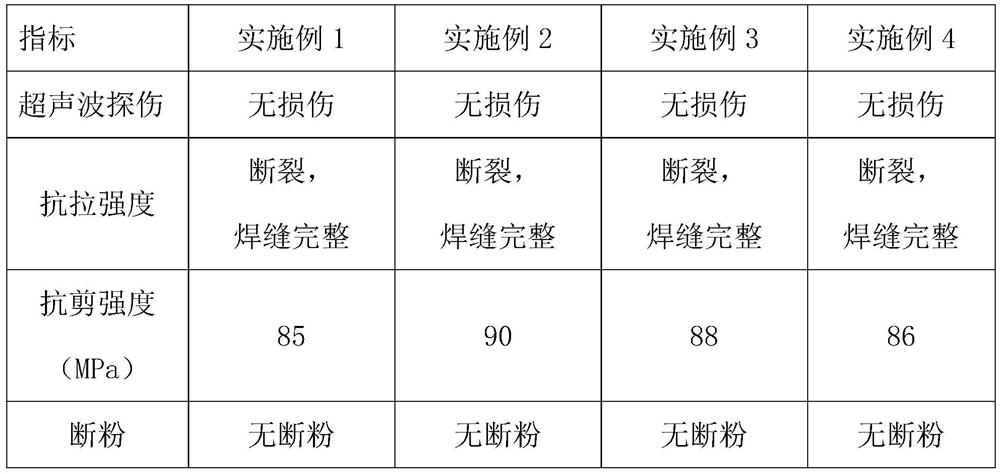

Examples

Embodiment 1

[0020] A seamless flux-cored welding wire for high-performance copper-aluminum containing rare earth elements, comprising the following components by weight:

[0021] Aluminum 1.9%, copper 0.2%, silver 2.3%, samarium 0.05%, cerium 0.05%, lanthanum 0.01%, europium 0.02%, gallium 0.02%, aluminum silicon alloy 0.6%, titanium alloy 0.1%, flux 18%, the rest are Zinc and inevitable impurities.

[0022] The total mass of cesium fluoroaluminate and potassium fluoroaluminate is calculated as 10, and the ratio thereof is cesium fluoroaluminate:potassium fluoroaluminate=8:2. The titanium alloy is a nickel-titanium alloy.

Embodiment 2

[0024] A seamless flux-cored welding wire for high-performance copper-aluminum containing rare earth elements, comprising the following components by weight:

[0025] Aluminum 2.2%, copper 0.5%, silver 2%, samarium 0.08%, cerium 0.05%, lanthanum 0.02%, europium 0.02%, gallium 0.02%, aluminum silicon alloy 0.8%, titanium alloy 0.1%, flux 23%, the rest are Zinc and inevitable impurities.

[0026] The total mass of cesium fluoroaluminate and potassium fluoroaluminate is calculated as 10, and the ratio thereof is cesium fluoroaluminate:potassium fluoroaluminate=9:1. The titanium alloy is a nickel-titanium alloy.

Embodiment 3

[0028] A seamless flux-cored welding wire for high-performance copper-aluminum containing rare earth elements, comprising the following components by weight:

[0029] Aluminum 2%, copper 0.3%, silver 2.1%, samarium 0.08%, cerium 0.05%, lanthanum 0.03%, europium 0.03%, gallium 0.02%, aluminum silicon alloy 1.1%, titanium alloy 0.1%, flux 20%, the rest are Zinc and inevitable impurities.

[0030] The flux is all cesium fluoroaluminate, and the titanium alloy is nickel-titanium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com